The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

21/02/2025 admin

A 2″-3″ stone power making machine, commonly known as a stone crusher or rock crusher, is designed to reduce large stones into smaller pieces, typically for use in construction, landscaping, or other industrial applications.

The entry point for the raw materials (stones) to be processed.

Jaw Crusher

Uses compressive force for breaking down the stones. The two jaws (one fixed and one movable) create a V-shaped chamber where the stones are crushed.

Impact Crusher

Uses impact force to break down the stones. A high-speed rotor with hammers impacts the stones, breaking them into smaller pieces.

Cone Crusher

Uses a rotating cone inside a stationary bowl to crush the stones by compressing them between the cone and the bowl.

Typically powered by an electric motor or diesel engine, providing the necessary force to crush the stones.

Where the crushed stone exits the machine. It can be adjustable to control the size of the output material.

Operates the machine and adjusts settings like the size of the output material.

Stones are fed into the feed hopper, which directs them into the crusher unit.

Depending on the type of crusher, the stones are crushed using compressive, impact, or shear forces.

The crushed material is discharged through the bottom of the crusher. The size of the output material can be adjusted by changing the settings on the crusher unit.

A 2″-3″ stone power making machine can process a variety of materials. The most common materials include:

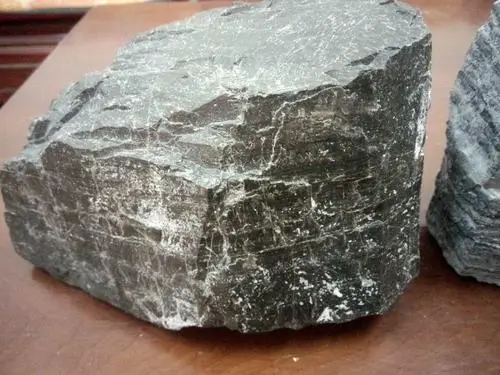

Granite:

Hard and durable, often used for construction aggregates, road bases, and decorative stones.

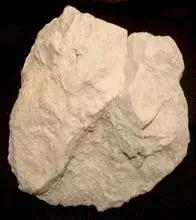

Limestone:

Softer than granite, commonly used for cement production, building materials, and road base.

Sandstone:

Medium-hardness rock used for building stone, road bases, and decorative stone.

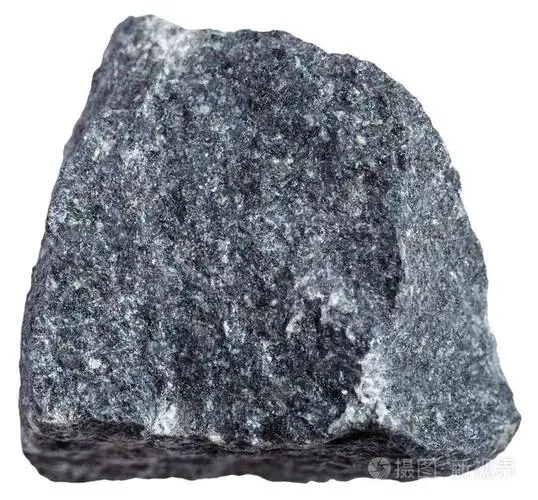

Basalt:

Very hard and dense, used in construction aggregates and road base.

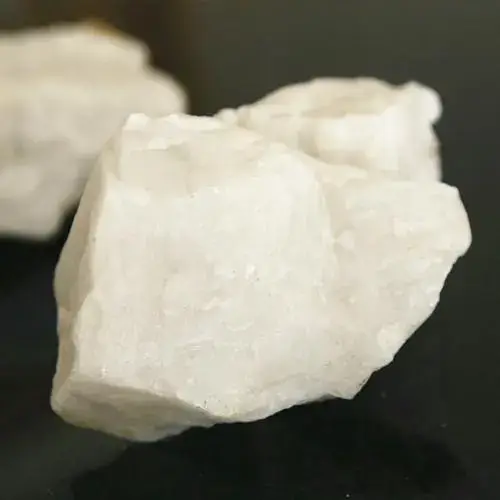

Marble:

Softer stone often used for decorative purposes and in the production of calcium carbonate.

Concrete and Asphalt:

Recycled materials from demolition sites can be processed into reusable aggregates.

Slate:

Fine-grained, used for roofing, flooring, and decorative purposes.

Iron Ore:

For mining operations to extract the mineral content.

Quartzite:

Hard and abrasive, used for construction aggregates and decorative stone.

Dolomite:

Similar to limestone, used in the production of cement and as a building material.

Coal:

For energy production and other industrial uses.

Gypsum:

Used in the production of plaster, wallboard, and cement.

Bauxite:

The primary ore of aluminum, used in aluminum production.

Phosphate Rock:

Used in the manufacture of phosphate fertilizers.

Clay:

Used in the production of bricks, ceramics, and cement.

Glass:

Recycled glass can be processed into cullet for reuse in new glass products.

Brick and Mortar:

Demolition debris can be crushed for reuse in construction.

Copper Ore:

Used in the extraction of copper for electrical wiring and other products.

Lead Ore:

Used in the production of lead and lead-based products.

Zinc Ore:

Used in the extraction of zinc for galvanizing steel and other applications.

Silica:

Used in the production of glass, ceramics, and as a sandblasting material.

Salt:

Rock salt can be crushed for use in de-icing and industrial applications.

Peat:

Used in gardening and as a fuel source.

Shells and Corals:

Used in the production of calcium carbonate and decorative materials.

Talc:

Used in the production of talcum powder, cosmetics, and as a filler in various products.

Graphite:

Used in the production of pencils, lubricants, and batteries.

Perlite:

Used in horticulture, construction, and as a lightweight aggregate.

Vermiculite:

Used in insulation, horticulture, and as a lightweight aggregate.

Mica:

Used in electrical insulators, cosmetics, and as a filler in plastics and paints.

Fluorite:

Used in the production of hydrofluoric acid and as a flux in steelmaking.

Barite:

Used in drilling mud for oil and gas wells and as a filler in paints and plastics.

Kaolin:

Used in the production of paper, ceramics, and as a filler in plastics and rubber.

Pyrite:

Used in the production of sulfuric acid and as a source of sulfur.

Manganese Ore:

Used in steel production and as a component in batteries.

Nickel Ore:

Used in the production of stainless steel and other alloys.

Platinum Group Metals (PGMs):

Used in catalytic converters, electronics, and jewelry.

Chromite:

Used in the production of ferrochrome and stainless steel.

Rare Earth Elements:

Used in electronics, magnets, and other high-tech applications.

Lithium Ore:

Used in the production of lithium-ion batteries.

Feldspar:

Used in the production of ceramics, glass, and as a filler in paints and plastics.

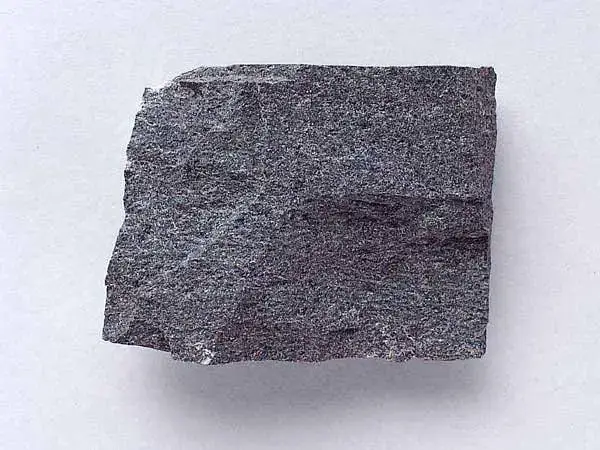

Gabbro:

Used in construction as a crushed stone or aggregate.

Tuff:

Used in construction and as a decorative stone.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.