1. Material Feeding:

The quicklime enters the mill via a controlled feeder system. This setup ensures the steady flow of material, preventing any operational interruptions.

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

11/03/2025 admin

In above quicklime grinding plant case, the customer using our HGM grinding mill as a stone dust making machine to process quicklime (calcium oxide) and calcium carbonate into a fine, 325 mesh powder.

Quicklime, due to its chemical properties, is in high demand for various industrial applications, including water treatment, chemical manufacturing, and construction.

The video linked shows the entire process of transforming raw quicklime into fine powder, detailing how each step contributes to producing a consistent, high-quality product.

The HGM Ultrafine Grinding Mill showcased in the video is specifically designed to handle quicklime efficiently, reducing it to 325 mesh. The HGM mill’s advanced grinding technology, featuring rotating rollers and a stationary grinding ring, allows it to achieve high precision and consistency in particle size.

The mill’s adjustable classifier plays a vital role in ensuring only particles that meet the 325 mesh standard pass through, while coarser particles are returned for further grinding.

The quicklime enters the mill via a controlled feeder system. This setup ensures the steady flow of material, preventing any operational interruptions.

Inside the mill, rotating rollers apply shear and compression forces to break down the quicklime particles, producing fine powder. The video highlights this grinding action, showing how the rollers and grinding ring work in unison.

As seen in the video, the classifier mechanism separates particles based on size. Only the fine 325 mesh powder exits the system, while oversized particles are redirected back into the grinding chamber.

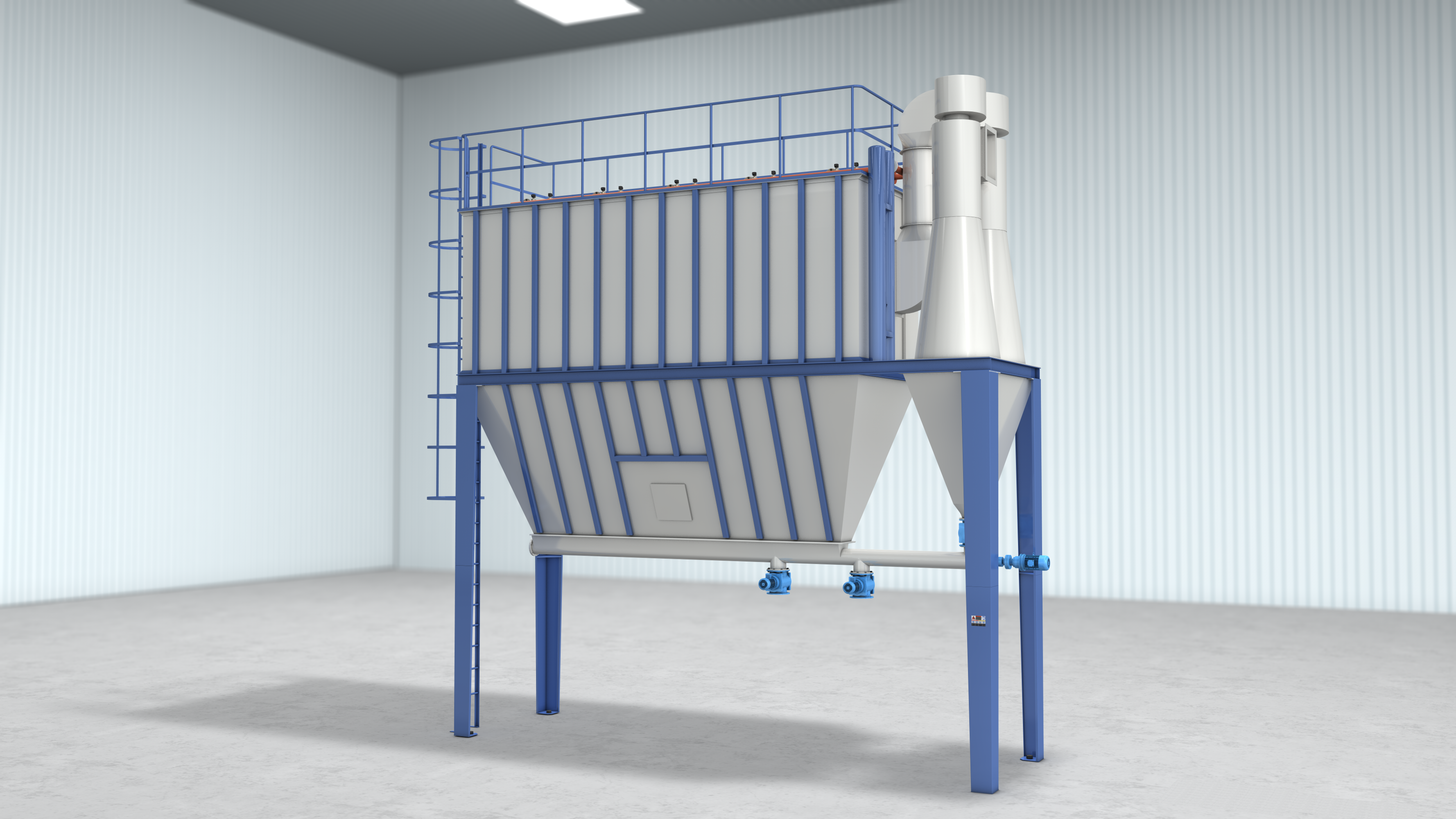

The video illustrates the importance of the dust collection system integrated into the quicklime grinding plant.

With components like a cyclone separator and bag filter, the system captures any dust generated during the grinding process, ensuring a clean environment and a high-purity product. This setup minimizes air pollution and improves safety, essential when handling reactive materials like quicklime.

One key highlight in the video is the consistency of the 325 mesh quicklime powder produced by the quicklime grinding plant. By adjusting operational parameters, the mill maintains a uniform particle size, meeting the specifications required for various end-use applications.

The 325 mesh quicklime powder produced by this quicklime grinding plant is valuable across multiple industries:

This video case study on the stone dust making machine for 325 mesh quicklime demonstrates the capabilities of the HGM ultrafine grinding mill in producing a high-quality, consistent fine powder. The machine’s advanced grinding, classification, and dust collection features make it an excellent choice for industries relying on precise and clean production of quicklime powder.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.