The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 1-20 T/H

Product features: High output, low energy consumption, high intelligent control system, wide adjustable range of fineness, high whiteness and good sphericity of the finished product

CLUM series activated carbon ultrafine vertical mill is an industrial ore pulverizer that integrates the functions of grinding, powder separation, secondary classification, and pneumatic conveying. It uses the principle of grinding machine to carry out ultra-fine grinding, avoiding the impact and wear between metals, and the metal wear is less.

Therefore, the ground activated carbon powder has high purity and is widely used in the pharmaceutical industry, fine chemicals, chemical raw materials, pharmaceutical intermediates, chemical raw materials, biopharmaceuticals, biochemical technology, decolorization, purification, refining and other fields of various preparation injections.

Adjustable fineness: 150-3000 mesh

Output: 1-20 t/h

Grindable materials: non-metallic ores with Mohs hardness less than 7, calcite, gypsum, barite, limestone, etc. It can also grind dry and hard materials such as shells, coconut shells, and cocoa shells.

CLUM ultrafine vertical mill has large output, low energy consumption and high grinding quality. It is suitable for the production of filler and coating grade calcium carbonate in large paper mills and large-scale ultra-fine powder processing enterprises.

The ultrafine powder products produced by CLUM ultrafine vertical mill are widely used in papermaking, plastics, rubber, PVC, wire and cable, artificial stone, paint and coatings and other industries.

CLUM ultrafine vertical mill production line consists of main machine, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc.

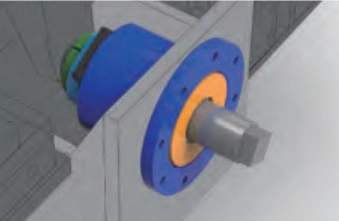

CLUM ultrafine vertical mill main machine is mainly composed of motor, reducer, body, grinding roller device, grinding disc device, pressure device, powder separator, lubrication station, hydraulic station and so on.

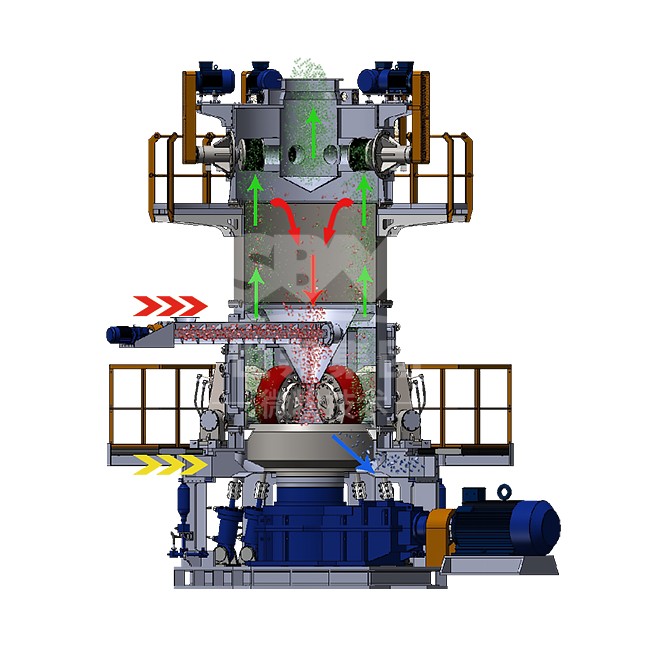

The motor drives the reducer to drive the grinding disc to rotate, and the materials to be ground are fed into the center of the rotating grinding disc by the feeding equipment. Under the action of centrifugal force, the material moves to the periphery of the grinding disc and enters the grinding roller table. Under the action of the pressure of the grinding roller, the material is crushed by extrusion, grinding and shearing.

At the same time, the wind is sprayed upwards evenly at a high speed from the air ring around the grinding disc, and the pulverized material is blown up by the high-speed airflow at the air ring, and the coarser material is blown back to the grinding disc for re-grinding.

The fine powder is brought into the classification machine by the wind for classification, and the qualified fine powder is milled along with the airflow, and collected by the dust collection equipment to be the product. The unqualified coarse powder falls back to the grinding table under the action of the blades of the classifying machine, and is re-ground together with the newly fed material. This cycle completes the whole grinding process.

The secondary classification system consists of ultra-fine classifiers, fans, dust collectors, silos, screw conveyors, pipes and other equipment. Powder classifier is its core equipment.

CLUM series ultrafine vertical mill is equipped with a classification system of secondary air separation, which has high powder selection efficiency and can effectively separate coarse powder and fine powder, and the separation fineness can reach 2μm.

High classification efficiency:

The classifier and fan are controlled by frequency conversion speed regulation. By adjusting the speed of the classifier and the impeller of the fan, the fineness of finished products of different specifications can be quickly obtained, and the classification efficiency is high.

Powder separator:

Single-head and multi-head powder separators can be used, and the fineness of the finished product can be adjusted freely.

The finished product has a wide range of fineness:

The fine particles of the material ground by the ultrafine vertical mill are sorted, and the fineness range of the sorting is 2um-45um. A vertical mill can produce products of different specifications, and can also produce products of the same fineness quickly and stably.

①

CLUM ultrafine vertical mill adopts the circulating air type grinding mill with its own high-efficiency classifier, which avoids the phenomenon of over-grinding, has high grinding efficiency and low energy consumption.

②

CLUM ultrafine vertical grinding system adopts advanced Siemens PLC automatic control system to realize intelligent and automatic control. During the production process, the equipment runs smoothly, and the ultrafine powder produced is of high quality and narrow particle size distribution.

③

The whole set of technological process is simple, the single-machine output is large, the sealing performance is good, the negative pressure operation is free of dust, the product quality control is fast, and the product replacement is flexible.

④

The conveying of finished products can be carried out in two ways: elevator conveying and pneumatic conveying, which are simple and convenient, and easy to operate and control.

⑤

CLUM ultrafine vertical mill runs stably and has little vibration, so the noise is low. The system is sealed as a whole and works under negative pressure, no dust spills, and the environment is clean.

⑥

The CLUM ultra-fine vertical grinding line is equipped with an expert automatic control system, which can realize the free switch between remote control and local control, which is easy to operate and save labor.

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Working Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 6 | 6 | 6 |

| Power of classifier (Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power (Kw) | 180-200 | 250-280 | 325-410 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output (t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output (t/h) | 3-4 | / | / |

Material: base on calcite

Particle size distribution: measured by microlayer diffraction particle size analyzer in British Malvern 3000 instruments

Model: CLUM

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.