We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorised as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyse the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customised advertisements based on the pages you visited previously and to analyse the effectiveness of the ad campaigns.

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 0.075-0.4 mm

Feed size.: <25 mm

Output: 1-200 T/H

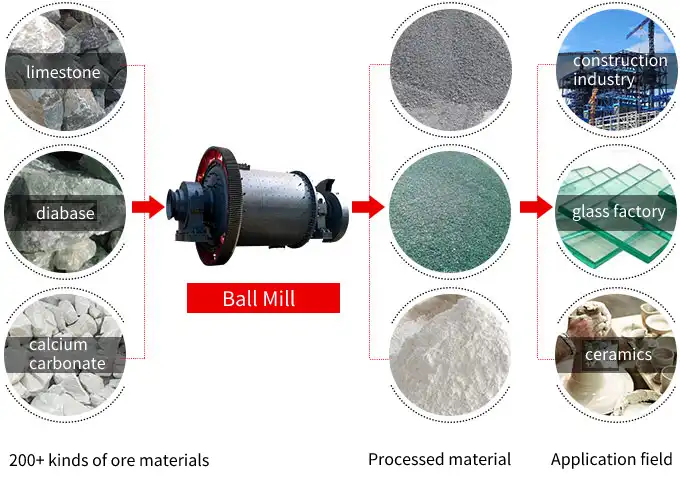

Applicable materials: various ores, gold-silver-copper-iron various metal beneficiation, cement, fertilizers, silicate products, refractory materials, glass, etc.

Product features: The ball mill has the characteristics of stable operation, reliable operation, large production capacity and long service life.

The ball mill is the key equipment for crushing the material after it is crushed. Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and non-ferrous metal beneficiation and glass ceramics and other production industries, dry or wet grinding of various ores and other grindable materials. The equipment has the characteristics of stable operation, reliable operation, large production capacity and long service life.

Note: In the case of no water addition, the ball mill grinds dry powder, also called dry ball mill, and water is added to grind the pulp during the beneficiation process, also called wet ball mill.

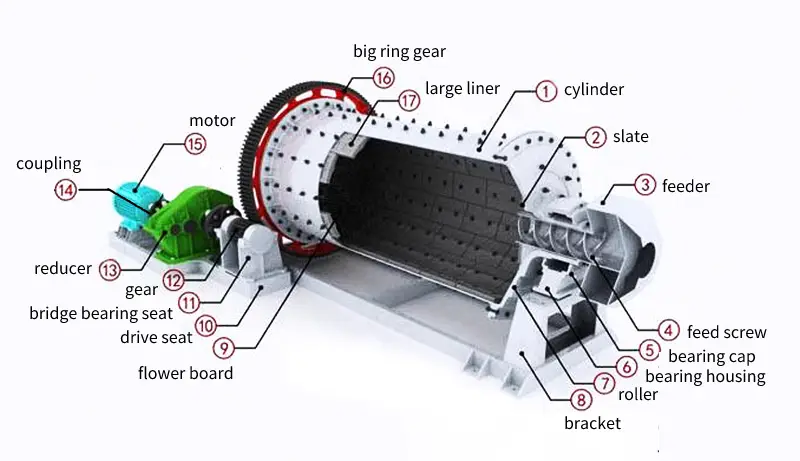

The ball mill is composed of main parts such as feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control). The hollow shaft is made of cast steel, the inner lining can be removed and replaced, the large rotary gear is processed by casting gear hobbing, and the cylinder is inlaid with a wear-resistant lining plate, which has good wear resistance. The machine runs smoothly and works reliably.

The main body of the ball mill includes a cylinder, which is inlaid with a lining made of wear-resistant materials, a bearing that carries the cylinder and maintains its rotation, and also has a driving part, such as a motor, and transmission gears, pulleys, V-belts, etc.

1. Cylinder: The cylinder is the main part of the ball mill. It is a circular device made of welded steel plates of a certain thickness. When working, it not only bears the static load of its own grinding medium, but also is affected by the alternating stress generated by the grinding medium impacting the rotation of the cylinder. Therefore, it must have sufficient strength and rigidity.

2. Bearing: The bearing is the supporting part of the ball mill, which carries the mass of the rotating part of the ball mill and the impact load of the grinding medium. Moreover, the rolling bearing is used instead of the sliding bearing, which has low running resistance and significant energy saving. It is also necessary to do a good job of lubrication and heat dissipation.

3. Transmission device: The ball mill is a heavy-duty, low-speed and constant-speed machine. Generally, the transmission device is divided into two forms: edge drive and center drive, including motor, reducer, drive shaft, edge drive gears and V-belts, etc.

4. Feeding and discharging device: The feeding and discharging device of the ball mill is mainly composed of an end cover with a hollow journal, a joint feeder, a fan-shaped liner and an inner sleeve of the journal.

(1) The main bearing adopts a large-diameter double-row spherical roller bearing instead of the original sliding bearing, which reduces friction and energy consumption, and the mill is easy to start.

(2) The structure of the end cover of the ordinary mill is retained, and the large-diameter inlet and outlet have a large processing capacity.

(3) The feeder is divided into two types: combined feeder and drum feeder, with simple structure and separate installation.

(4) There is no inertia impact, the equipment runs smoothly, and the downtime of the mill for maintenance is reduced, and the efficiency is improved.

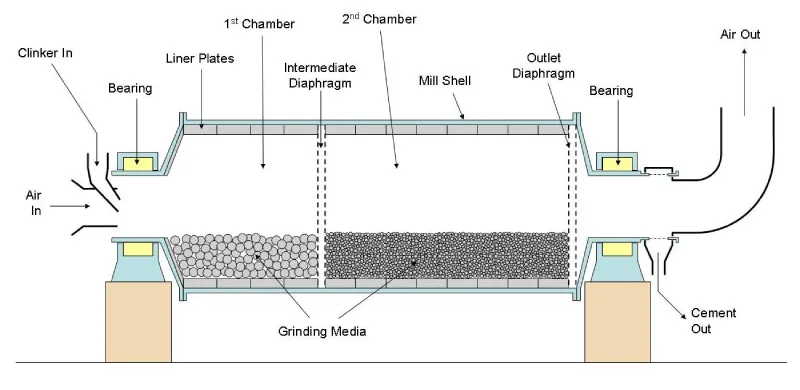

The material enters the first chamber of the mill evenly and spirally from the feeding device through the feeding hollow shaft. There are stepped lining plates or corrugated lining plates in the bin, and steel balls of different specifications are installed inside. The rotation of the cylinder generates centrifugal force, which brings the steel ball to a certain height and then falls, which has a heavy impact and grinding effect on the material.

After the material reaches the rough grinding in the first bin, it enters the second bin through the single-layer partition board. The silo is inlaid with a flat lining plate with steel balls to further grind the material. The powder is discharged through the discharge grate to complete the grinding operation.

1. Strong adaptability

The ball mill has strong adaptability, can grind most materials and mix them uniformly, and can adapt to the operation in different environments.

2. Meet different needs

It can operate continuously, and the production capacity can reach more than 200 tons per hour, which meets the needs of modern industrial large-scale production.

3. Strong sealing

The ball mill equipment has a good sealing device, strong sealing, and can be operated under negative pressure to prevent dust from flying.

4. The material has high wear resistance

The casting turning device is adopted, the hollow shaft is made of cast steel, the steel plate is planed, and the flanges at both ends of the cylinder are made of large CNC cylinder lathes. The special processing technology can fully meet the requirements of concentricity and has good wear resistance.

5. Low energy consumption

The ball mill adopts a wave-type annular lining plate, which increases the contact surface between the ball and the ore, strengthens the grinding effect, and has the ability to lift the ore, reducing energy consumption.

6. Long bearing life

The bearings used in the ball mill are not only advanced in material, but also refined in the manufacturing process, which increases the service life by about 15% compared with the traditional ball mill bearings.

| Model | Rotary speed(r/min) | weight(t) | Input size(mm) | Discharge size(mm) |

Capacity(t/h) | Motor power (kw) | Weight (t) |

|---|---|---|---|---|---|---|---|

| Ф900×1800 | 39 | 1.5 | ≤20 | 0.075-0.89 | 0.8-2 | 18.5 | 4.6 |

| Ф900×1800 | 39 | 2.7 | ≤20 | 0.075-0.89 | 1-4 | 22 | 5.6 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Ф1200×4500 | 32 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Ф1500×3000 | 27 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| Ф1830×3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| Ф1830×6400 | 24 | 21 | ≤25 | 0.074-0.4 | 7-16 | 210 | 34 |

| Ф1830×7000 | 24 | 23 | ≤25 | 0.074-0.4 | 8-18 | 245 | 36 |

| Ф2100×3600 | 23 | 19 | ≤25 | 0.074-0.4 | 10-36 | 210 | 46 |

| Ф2200×4500 | 21 | 27 | ≤25 | 0.074-0.4 | 12-23 | 280 | 48.5 |

| Ф2200×6500 | 21 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

| Ф2200×7000 | 21 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| Ф2200×7500 | 21 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 18-45 | 320 | 65 |

| Ф2400×8000 | 20 | 36 | ≤25 | 0.074-0.4 | 20-48 | 410 | 81 |

| Ф2700×3600 | 21 | 39 | ≤25 | 0.074-0.4 | 19-75 | 400 | 83 |

| Ф2700×4000 | 20 | 40 | ≤25 | 0.074-0.4 | 20-78 | 400 | 85 |

| Ф2700×4500 | 20 | 48 | ≤25 | 0.074-0.4 | 22-85 | 430 | 89 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 29-140 | 800 | 137 |

| Ф3200×5400 | 18 | 81.6 | ≤25 | 0.074-0.4 | 30-180 | 800-1000 | 146 |

| Ф3600×4500 | 17 | 88 | ≤25 | 0.074-0.4 | 35-210 | 1000 | 190 |

| Ф3600×6000 | 17 | 117 | ≤25 | 0.074-0.4 | 38-240 | 1250-1500 | 220 |

| Ф3600×8500 | 17 | 144 | ≤25 | 0.074-0.4 | 45-260 | 1800 | 260 |

The wearing parts of the ball mill mainly refer to the lining plate. The wear and service life of the lining plate are related to the use cost and production effect of the ball mill. So how to distinguish the pros and cons of the liner?

Mainly from three aspects, first look at the casting and smelting process of the lining plate, secondly look at whether the quenching and tempering treatment of the lining plate is qualified, and finally look at the material of the lining plate.

At present, the common lining materials on the market include high-chromium cast iron, low-alloy wear-resistant cast steel, high-manganese steel, etc. The linings of the three materials have good wear resistance.

Help customers to select equipment

Free arrangement of engineers to the site for actual survey and plan design

Strict implementation of quality standards, quality assurance of ex-factory products

Free logistics and transportation information, more choices for logistics and transportation

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

Free arrangements for engineers to guide the basic production of equipment

Provide free technical guidance for equipment installation and commissioning

The free on-site one-to-one operation, repair, maintenance, and other training

Professional after-sales service team, 24 hours response to customer needs

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

CE, ISO9001

factory sell directly

30 years experience, professional

Payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.