Raymond mill is a high-efficiency pulverizing mill that replaces ball mill to process ore powder.It has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance.

Discharge fineness: 80-500 mesh

Feed size: <35 mm

Output: 1-35 t/h

Materials: Quartz, feldspar, barite, carbonate calcite, limestone, talc, ceramics, iron ore, emery, bauxite, phosphate rock, coal and other materials, a total of

Product features: Raymond mill has a small footprint, environmental protection and energy saving. The production of the production has fine texture, uniform particles, less impurities, and the screening rate is as high as 99%

Barite is a non-metallic mineral, mainly composed of barium sulfate. Barite is a very important non-metallic mineral raw material, with stable chemical properties, insoluble in water and hydrochloric acid, non-magnetic and toxic. It can be used in industrial production, such as rubber, cement, paint, mortar, concrete, etc. Barite is widely distributed, and the barite grinding line is a promising development project.

Raymond flour mill is the core equipment for barite processing. The finished product size can be processed between 80-500 meshes. Raymond flour mill occupies a small area and is environmentally friendly and energy-saving. The product has fine texture, uniform particles, less impurities and a screening rate of 99%.

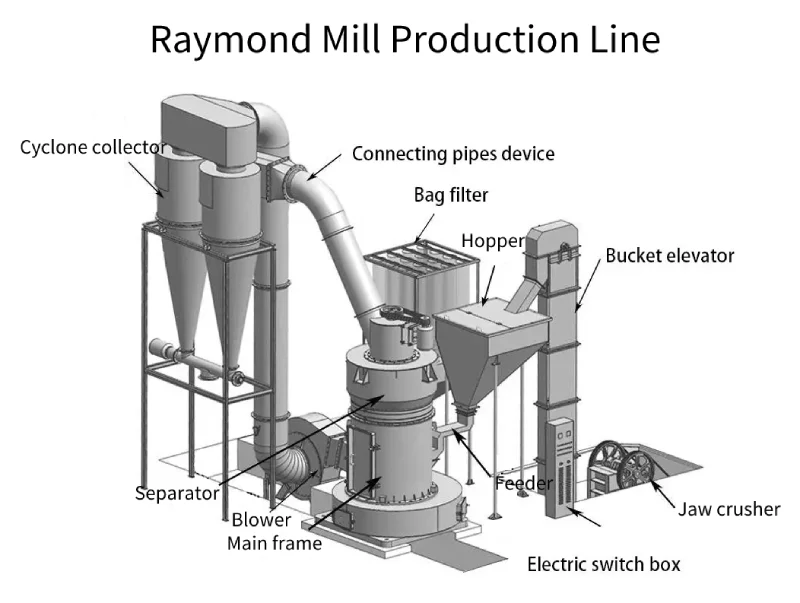

The equipment required for barite grinding mainly includes jaw crusher, Raymond mill and vibrating screen.

The jaw crusher is mainly used for crushing barite, breaking large pieces of materials into small particles, which is convenient for processing by Raymond mill. Jaw crusher has simple structure, convenient operation, large crushing ratio, stable operation process, high yield and strong safety performance. It is a common equipment in the mining processing production line.

The whole working process of the barite Raymond mill (the process of grinding the barite material): after the massive barite material is crushed to the required particle size by the jaw crusher, the material is sent to the storage hopper by the elevator, and then sent to the main machine grinding room of the barite Raymond mill for grinding uniformly, quantitatively and continuously by the vibration feeder. The powder after grinding is taken away by the fan airflow. Classified by the analyzer, the fine powder flows through the pipeline into the cyclone collector for separation and collection, and then is discharged through the powder tube as barite powder.

1. High fineness of finished products and high screening rate

Raymond mill mesh can reach 325 mesh, high fineness of finished products; And the screening rate can reach 98%.

2. Low investment cost and stable operation

The driving device of Raymond mill adopts sealed gear box and pulley, which ensures stable and reliable operation; Under the condition of the same fineness, the initial input is less than that of air flow mill, and the return period is shorter.

3. Low energy consumption per unit time, economic and environmental protection

The important accessories of Raymond mill are made of high manganese steel. The wear resistance of vulnerable parts is enhanced, and the sealing performance is better. With the same fineness and power consumption of finished products, the output of Raymond mill is more than 45% higher than that of air flow mill and stirred mill. Besides, there is less dust during operation, which is economic and environmentally friendly.

4. Safe and reliable operation in grinding chamber, long service life

There is no rolling bearing or screw in the grinding chamber of Raymond mill, so there is no problem that the bearing and other seals are easy to wear. At the same time, the damage to the machine due to the loosening of the screws can be avoided. The operation safety in the grinding chamber is improved, and because each part is made of high-quality wear-resistant materials, it is durable and has a longer service life.

| Model | Roller | Ring | Main Shaft Speed(r/min) | Feeding Size(mm) | Finished fineness (Mesh) |

Motor(kw) | Capacity(t/h) | ||

|---|---|---|---|---|---|---|---|---|---|

| Qty(pcs) | Size(mm) | External Dia(mm) | Height(mm) | ||||||

| CLRM9720 | 3-4 | Φ320*200 | 1077 | 200 | 145 | <20 | 80-500 | 45*15*37 | 1-7 |

| CLRM1280 | 3 | Φ370*240 | 1280 | 240 | 125 | <20 | 80-400 | 75*15*55 | 2-12 |

| CLRM1300 | 4 | Φ410*280 | 1390 | 280 | 112 | <20 | 80-400 | 110*22*90 | 3-15 |

| CLRM1620 | 4 | Φ450*300 | 1620 | 300 | 102 | <20 | 80-400 | 160*30*132 | 5-20 |

| CLRM1700A | 4 | Φ510*300 | 1700 | 300 | 102 | <30 | 80-325 | 185*37*160 | 6-25 |

| CLRM1720 | 4 | Φ510*300 | 1850 | 300 | 92 | <35 | 80-325 | 250*45*185 | 6-25 |

| CLRM1900A | 4 | Φ600*300 | 1900 | 300 | 92 | <35 | 80-325 | 250*45*220 | 8-32 |

| CLRM2150 | 4 | Φ600*300 | 2150 | 300 | 85 | <35 | 80-325 | 315*45*280 | 12-35 |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.