We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorised as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyse the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customised advertisements based on the pages you visited previously and to analyse the effectiveness of the ad campaigns.

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

16/09/2021 admin

Basalt stone crusher machine can crush basalt into small particles and is widely used in the construction industry. The basalt crusher has stable working performance, simple operation, convenient maintenance, high wear resistance, long service life, and low cost. Very suitable for crushing harder ores, such as quartz, granite, marble, feldspar, etc.

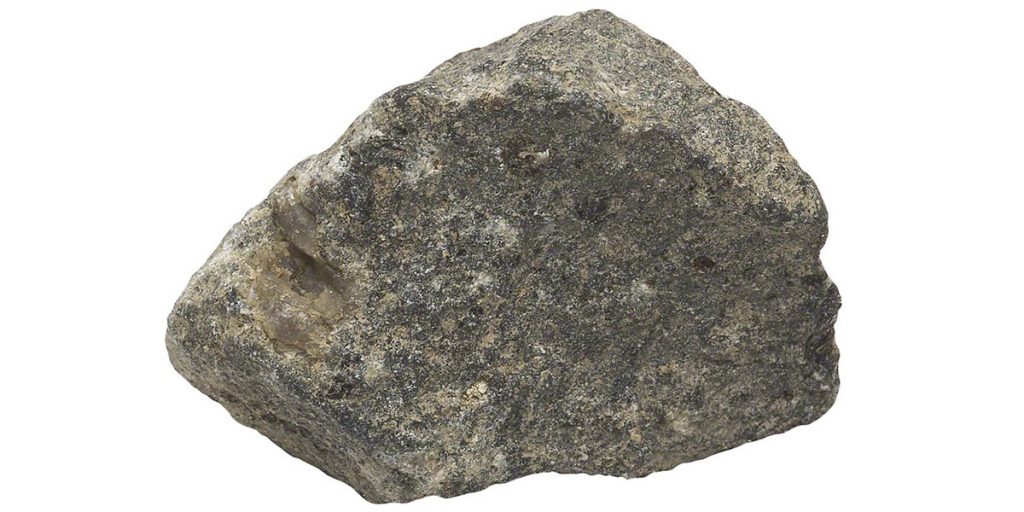

Basalt is dark in color, generally black, sometimes grayish-green, and dark purple, etc., showing a porphyritic structure. The bulk density is 2.8~3.3g/cm3, and the compact one has a high compressive strength, which can be as high as 300MPa. Basalt is very durable, has many joints, and is brittle, so it is not easy to mine large stones.

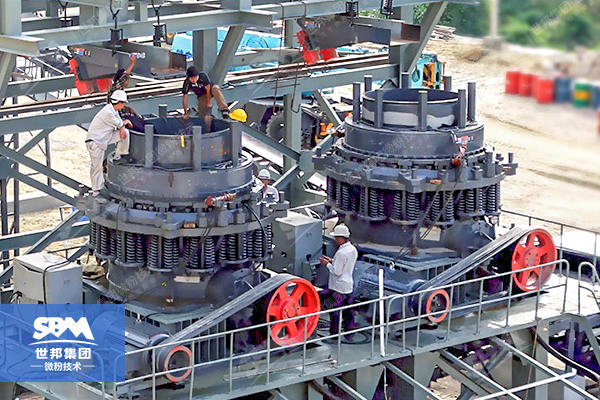

The Mohs hardness of basalt reaches 5-7, and the content of SiO2 is 45%-52%. Therefore, the impact crusher is generally not used for basalt crushing, and the cone crusher is more used for the second and third stage medium and fine crushing operations.

Because basalt has strong hardness and rich silicon content, this leads to serious wear of the jaw plate, hammer, impact plate, and other wear parts in the crushing operation of basalt. This greatly increases the crushing cost of basalt. Therefore, for the special properties of basalt, crushing equipment using the lamination principle should be selected as much as possible when crushing to reduce the loss of wear-resistant parts. The basalt cone crusher is the equipment that must be used in the basalt crushing production line.

Stage 1: Primary coarse crushing

The large basalt that has just been mined is sent to the jaw crusher by the vibrating feeder through the silo for coarse crushing, and the materials after the coarse crushing are transported to the next process by the conveyor.

Stage 2: Medium and fine crushing treatment

The conveyed materials are evenly fed into the cone crusher by the vibrating feeder for medium and fine crushing of the materials.

Stage 3: Material screening

The materials crushed by the cone crusher are screened by the circular vibrating screen, the materials that meet the requirements of the sand making particle size are sent to the sand making machine, and the materials that do not meet the requirements are transported to the cone crusher by the conveyor Broken again in the machine.

Stage 4: Sand making

The materials that meet the requirements of sand-making granularity enter the sand-making machine for crushing and shaping.

For many stone yards that do not have high requirements on the size of the stone, it is recommended to use a jaw crusher and a hydraulic cone crusher to build a production line. Because jaw crushers and hydraulic cone crushers are crushing equipment using the lamination principle, this type of equipment has relatively little wear on the wear parts, so the production cost is relatively low.

However, due to the principle of lamination, the cracks in the broken stone will be more serious. In addition, the particle size of the stone is not very good, and the content of the needle-like stone is relatively high, which makes it unable to achieve the mechanical properties of the multi-sided cubic stone in the building with the original smooth stone in nature. This is unwilling to accept high-grade buildings, so the price of this type of stone is relatively much cheaper.

The process configuration of jaw crusher→single-cylinder cone crusher→full hydraulic cone crusher→reaction crushing is adopted. After the basalt is crushed with high efficiency and low loss, small-grained stones are reshaped by impact crushing. It can make up for the shortcomings of machine-made stones after being laminated and broken so that the quality of the stones is the same as that of natural sand and gravel. Therefore, the use of impact crushers or impact crushers to shape the conical crusher crushed stone has become a common method for machine-made sand and gravel.

Compact and simple

Stable performance

Large discharge opening adjustment range

Larger broken ratio

Energy-saving of equipment

The strong wear resistance of parts

Uniform product size

Easy maintenance

Low consumption of wearing parts, low operating cost, reasonable structure, reliable operation, and all parts of the crusher are protected against wear

Thin-oil lubrication, reliable and advanced, improve the service life

Large crushing ratio and high production efficiency

Hydraulic protection and hydraulic cavity clearing, high degree of automation, reducing downtime

The shape of the product is cubic and the grain is good

The discharging particle size can be adjusted to simplify the crushing process

High chromium plate hammer, impact resistance, abrasion resistance, and high impact force

Keyless connection, convenient maintenance, economical and reliable

Compact structure and strong machine rigidity

Mixing station, highway, bridge construction, and other fields

Production fineness: 0-5-18mm

Basalt is an excellent material used in the construction of roads, railways, and airport runways. It has the advantages of strong compression resistance, low crushing value, strong corrosion-resistance, and high asphalt adhesion.

Used in the building materials industry

Production fineness: 0-5-18mm

Basalt has excellent compressive and flexural performance, good abrasion resistance, and low water absorption. It is also a very good building decoration material and can be widely used for indoor and outdoor decoration.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.