The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

05/08/2021 admin

The calcite industrial ultrafine powder grinder is highly energy-efficient, stable, and environmentally friendly, and can grind calcite into superfine powder (300-3000 mesh). In addition to calcite, it can also grind more than 100 other ores into powder. Such as talc, limestone, dolomite, bentonite, marble, gypsum, etc.

Calcite is a calcium carbonate mineral with a very wide distribution. It occupies more than 40% of the total earth’s crust, with no less than 200 species. It is most common in natural calcium carbonate.

The crystal shapes of calcite are various, and their aggregates have clusters of crystals, and there are also granular, massive, fibrous, stalactite, earthy, and so on.

Because the impurities contained in calcite are different, its color is also different. For example, when it contains iron and manganese, it is light yellow, light red, brown-black, and so on. But generally, it is white or colorless.

Generally, calcite is used as industrial raw material such as chemical industry and cement.

Calcite is used as a flux in the metallurgical industry. Used in the construction industry to produce cement and lime.

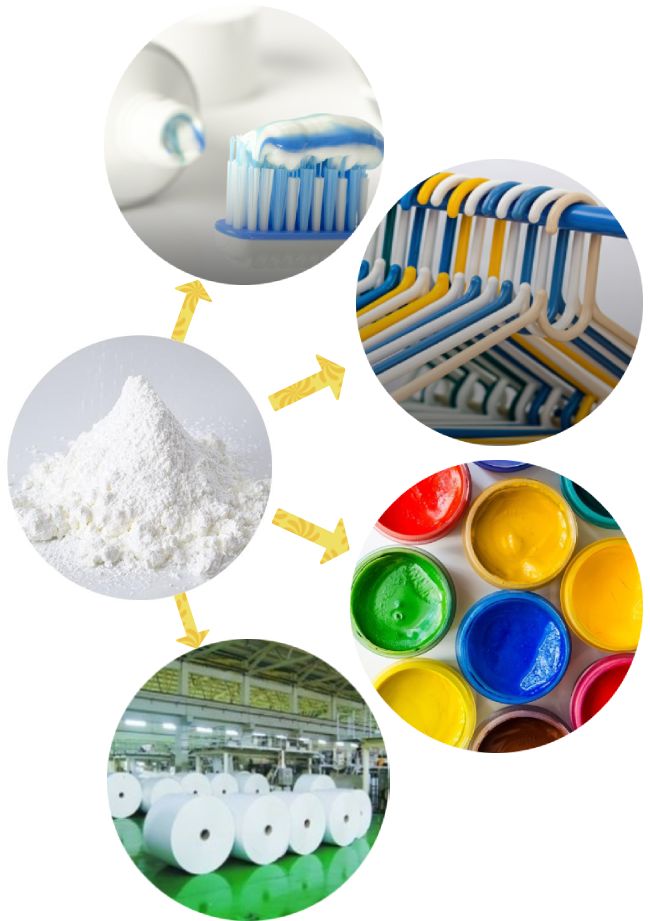

It is also used to make high-quality putty powder, plastic, paper, toothpaste. In food, it is used as a filling additive.

In glass production, adding calcite, the resulting glass will become translucent, which is especially suitable for making glass lampshades.

In China, calcite is still a common Chinese medicine. It can treat osteoporosis, prevent arteriosclerosis, memory loss, eliminate odor and moisture.

Calcite, widely distributed, hardness 2.7-3.0, specific gravity 2.6-2.8, also called stalactite, stalagmite white marble, and so on. The main component of calcite is calcium carbonate, and its main purpose is to make heavy calcium powder and light calcium powder. Calcite powder of different fineness is widely used in many fields such as papermaking, medicine, chemical industry, and agriculture.

1. Crushing stage:

Large pieces of calcite are evenly fed into the crusher by the vibrating feeder for crushing, and the crusher is equipped with a processing dust removal machine. The crushed calcite is sent to the second crusher (impact crusher or cone crusher) by belt conveyor for further crushing.

2. Screening stage:

The crushed calcite is sent to the vibrating screen by a belt conveyor for screening. Several different sizes and specifications of calcite are screened out, and the calcite that meets the particle size requirements is sent to the finished product pile by the finished product belt conveyor.

3. Grinding stage:

The feeding system sends the calcite in the finished product pile uniformly and quantitatively to the grinding chamber of the calcite industrial ultrafine powder grinder and grinds it into powder in the grinding cavity.

4. Classification stage:

The ground calcite powder is classified by the separator along with the system airflow, and the unqualified powder is returned to the main machine’s grinding cavity for re-grinding.

5. Powder collection stage:

Calcite powder that meets the fineness enters the powder collection system through the pipeline with the airflow, and the gas and powder are separated. The finished product powder is sent to the finished product silo by the conveying device. Finally, it is packed with a powder tanker or automatic packing machine.

Calcite can be ground into powder by industrial milling equipment, and calcite powder has a wide range of uses. Common calcite powder has 3000 mesh, 2500 mesh, 2000 mesh, 1000 mesh, 1500 mesh, 1250 mesh, 800 mesh, and so on. They are applicable to different fields. The following two SBM industrial grinding mills are independently developed and produced based on our 30+ years of experience. They can produce 300-3000 mesh ore powder, which can meet the processing of ultrafine calcite powder. Of course, if you need to produce calcite powder below 300 mesh, we also have YGM Raymond mill, which can grind 80-600 mesh calcite powder.

For all the equipment of the calcite production line and more calcite knowledge, welcome to visit: calcitegrindingmill.com

As an industrial ultrafine powder mill for the calcite industry, this equipment has the advantages of small footprint, simple operation, convenient maintenance, high grinding efficiency, environmental protection, and low investment.

Finished product fineness: 300-2500mesh.

Capacity: 0.2-45t/h.

HGM ultrafine grinding mill can also be used to grind non-metallic minerals such as talc, mica, barite, graphite, and carbon black.

CLUM ultra fine vertical mill has higher output and better powder shape than the HGM series powder grinder. It is more suitable for processing industries with high-quality requirements.

As a calcite industrial ultrafine powder grinder, it can produce up to 3000 mesh calcite powder. The production efficiency is high, the service life is long, and it has a certain drying function.

This equipment can be widely used in chemical, metallurgy, non-metallic mining, and other industries. Especially in the field of ultra-fine grinding and processing of white non-metallic minerals, with outstanding performance. It can provide high-quality fillers and additives for papermaking, coatings, plastics, rubber, PVC, ink, and other industries.

Rubber industry

Heavy calcium carbonate powder for rubber-rubber: 400 mesh, whiteness: 93%, calcium carbonate: 96%.

Calcium carbonate is one of the largest fillers used in the rubber industry. It can increase the volume of rubber products and save expensive natural rubber, thereby greatly reducing costs.

Filling calcium carbonate in rubber can obtain higher tensile strength and tearing strength than pure rubber vulcanizates. Crack strength and abrasion resistance.

Plastic industry

Heavy calcium carbonate powder (heavy calcium powder) 400 mesh for plastic masterbatch and color masterbatch. The whiteness should not change after high-temperature heating. The ore structure is large crystalline calcite, calcium carbonate content: 99 %, whiteness: 95%.

Calcium carbonate can play a role as a skeleton in plastic products and has a great effect on the dimensional stability of plastic products.

Paint industry

Heavy calcium powder paint for paint industry – heavy calcium carbonate (heavy calcium powder) 800 mesh or 1000 mesh for latex paint, whiteness: 95%, calcium carbonate: 96%.

Calcium carbonate is also used in the paint industry. For example, the amount in thick paint is more than 30%.

Paper industry

Heavy calcium powder for paper industry – heavy calcium carbonate (heavy calcium powder) for papermaking: 325 mesh, whiteness requirement: 95%, calcium carbonate content: 98%.

Calcium carbonate plays an important role in the paper industry. It can ensure the strength and strength of paper. Whiteness, and low cost.

Calcite can be used as medicine. It has the effects of clearing heat and dampness, clearing the veins and detoxification, and has a therapeutic effect on chest fever, thirst, jaundice, and other symptoms.

Calcite can reduce capillary permeability.

Calcite can inhibit fluid extravasation and edema.

Calcite can inhibit nerve stress function.

Calcite can treat osteoporosis, prevent arteriosclerosis, memory loss, eliminate peculiar smell and moisture.

Beautiful stones are called jade. Calcite is a mineral such as white marble, which is calcium carbonate. Using calcite as jewelry is a recent thing, it is neither good nor harmful to the human body.

170+

Our products are exported to more than 170 countries and regions around the world.

30+

More than 30 overseas branches and business organizations.

30+

More than 30 overseas branches and business organizations.

10

Ranked No. 1 in China’s mining machinery industry for ten consecutive years.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.