The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

23/09/2022 admin

Calcite is a calcium carbonate mineral that is generally white or colorless. Calcite is usually used as a filler after being ground into powder, and is widely used in artificial floor tiles, natural rubber, synthetic rubber, coatings, plastics, composite new calcium plastics, cables, paper, toothpaste, cosmetics, glass, medicine, etc.

The price of calcite powder often depends on its calcium content, whiteness, fineness and particle uniformity. Therefore, in addition to the calcium content and whiteness of the calcite raw material itself, the whiteness of the calcite after being ground into powder mainly depends on the grinding machine.

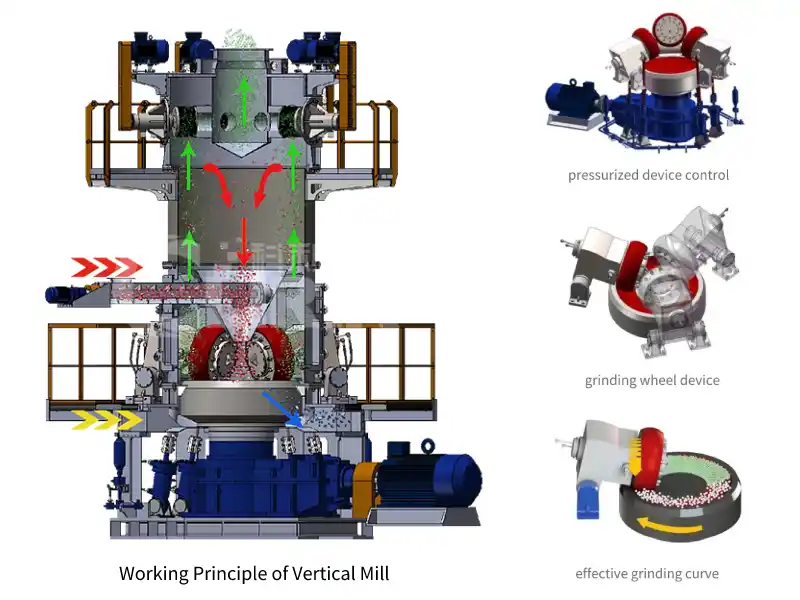

The CLUM vertical mill independently developed by our company, its grinding rollers and grinding discs are made of high wear-resistant materials. The powder particles come out in good shape.

The calcite powder ground by CLUM vertical mill has a fineness of D97 up to 3000 mesh and a content of 2μm up to 70%. The powder has high whiteness, no impurities, high purity, narrow particle size distribution and good particle sphericity. It is a high-quality calcite powder, used as a filler in high-end fields, so the price is also higher. So, our CLUM vertical mills have a higher return on investment and can be used in high-volume, high-quality calcite powder production lines.

CLUM series vertical roller mill is a new type of superfine crushing equipment that integrates powder grinding, grading, conveying, secondary powder selection, and finished product packaging.

The fineness of the finished powder can be freely adjusted between 150-3000 mesh, the output is 1-20t/h, the operation is stable, the operation is intelligent, energy saving and environmental protection, and the accessories have a long service life.

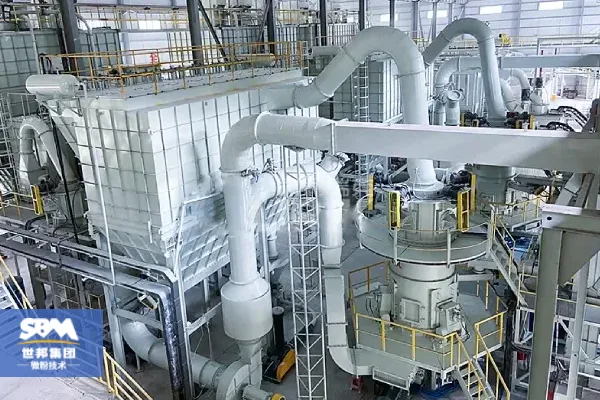

The primary crushing system mainly includes raw material crushing, raw material transportation, ultra-fine crushing and classification, finished product collection, finished product transportation, finished product storage, and auxiliary equipment.

The secondary powder selection system is mainly composed of multi-rotor ultrafine powder separator, fan, pulse dust collector, elevator, discharge valve, screw conveyor, finished product tank, etc.

Stage 1: Broken

The large pieces of calcite are evenly sent to the crusher by the vibrating feeder through the silo for crushing. The crusher is equipped with a processing dust collector, and the crushed calcite is sent to the second crusher (impact crusher or cone crusher) by the belt conveyor. Crusher) for further crushing to the fineness (15mm-50mm) that can enter the mill.

Stage 2: Grinding

The crushed calcite small pieces are sent to the silo by the elevator, and then sent to the grinding chamber of the CLUM vertical mill evenly and quantitatively by the vibrating feeder for grinding.

Stage 3: Grading

The pulverized material is classified by the powder separator, and the unqualified powder is classified by the powder separator and then returned to the main engine for re-grinding.

Stage 4: Gathering Powder

The powder that meets the fineness enters the dust collector through the pipeline with the airflow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is uniformly packed by a powder tanker or an automatic baler.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.