The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 325-3000 mesh

Feed size: <20mm

Output: 1-20 T/H

Product features: 1. High Efficiency &High Quality of Finished Products. 2. Advanced Separation Technology & Energy Efficiency. 3. Intelligentized Control System & Stable Operation. 4. Environmentally-friendly.

Calcium carbonate ultrafine powder vertical mill is independently designed by SBM on the basis of years of mill production experience. Clum series calcium carbonate ultrafine powder vertical mill adopts the latest grinding roller technology from Taiwan and powder selection technology from Germany. The ultrafine vertical mill integrating ultrafine powder grinding, grading and conveying has become a better choice for the ultrafine powder grinding industry.

Calcium carbonate ultrafine powder vertical mill is widely used in Paper Making, Plastic, Rubber, Tire, PVC, Cable, Floor, Artificial Stone, Painting, Tooth, Agricultural Film, Cosmetics and many other fields because of its excellent properties.

Calcium carbonate ultrafine powder vertical mill is widely used in various industries due to its ability to produce high-quality, ultra-fine powder of various materials. Some common areas of application for ultrafine vertical mills are:

1. Papermaking: Calcium carbonate ultrafine powder vertical mill is widely used in the field of papermaking. Calcium carbonate is a common filler material used to increase the whiteness, gloss and optical properties of paper. In the papermaking process, calcium carbonate superfine powder is pulverized and finely ground by a vertical mill to control the particle size of the powder within a smaller range.

2. Pharmaceuticals: Calcium carbon ultrafine powder vertical mill is widely used in the pharmaceutical industry for the production of pharmaceuticals and other pharmaceutical products. It is used to grind active ingredients, excipients and other raw materials to form powders of consistent particle size and shape.

3. Ceramics: Calcium carbonate ultrafine powder vertical mill is used in the ceramic industry to produce fine powder of ceramic materials, such as alumina, zirconia, silica, etc. These powders are then used to manufacture high-quality ceramic products such as ceramic tiles, tableware and electronic components.

4. Pigment: Calcium carbonate ultrafine powder vertical grinding mill is used in the pigment industry to produce high-quality pigments with consistent particle size and color. These pigments are used in a variety of applications such as paints, coatings, inks and plastics.

5. Coatings: Calcium carbonate superfine powder vertical mill is used in the coatings industry to produce high-quality coatings with consistent particle size and thickness. These coatings are used in a variety of applications, such as automotive coatings, marine coatings and industrial coatings.

6. Adhesives: Calcium carbonate ultrafine powder vertical grinding machine is used in the adhesive industry to produce fine powder of adhesive materials such as resins and polymers. These powders are then used to create high-quality adhesives with consistent bond strength and viscosity.

7. Food and beverage: Calcium carbonate pulverized grind is used in the food and beverage industry to produce fine powder of various food ingredients, such as spices, flavors, extracts, etc. These powders are then used to enhance the flavor and aroma of foods.

8. Mining and minerals: Calcium carbonate ultrafine powder vertical mill is used in mining and mineral industry to produce ultrafine powder of gold, silver, copper and other minerals. These powders are then used in various applications such as ore processing and metallurgy.

1. Higher yield and better quality

In order to avoid the problems of long material residence time, repeated grinding, and high iron content in the grinding process of traditional mills, SBM specially designed a unique grinding curve for the roller shell and liner. This design makes it easier to generate material layers, and can achieve high output in one grinding, which can greatly improve the working efficiency of the mill and improve the whiteness and cleanliness of the finished product.

2. More energy-saving multi-head powder selection technology

SBM adopts PLC control system and multi-head powder selection technology in this mill, which completely solves the two problems of “high precision and accurate cutting powder diameter and quick switching of different production requirements”. Users can precisely control the working parameters of equipment such as grinding pressure and rotating speed. Compared with ordinary mills, the energy consumption of this mill is reduced by 30%-50%.

3. Double limit technology, more stable operation

In the calcium carbonate superfine powder vertical mill, the contact point between the grinding roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive effects caused by machine vibration (such as the direct crushing of the grinding roller and the grinding disc) ( Such as the grinding roller directly crushing the grinding disc). machine vibrations caused by mine explosions) and ensure operational stability.

4. Reversible structure makes maintenance more convenient

During the design process of calcium carbonate superfine powder vertical mill, SBM fully considered the possible maintenance problems caused by heavy grinding rollers, and finally developed and designed a reversible structure. Through this structure and hydraulic adjustment system, the operator can conveniently and quickly move the grinding roller out of the body for inspection, replacement of roller shell and liner and other maintenance operations, thereby reducing downtime losses.

5. Digital processing, higher precision

Calcium carbonate superfine powder vertical mill has dozens of lines of CNC machine tools. The cutting, bending, planing and milling, painting and other operations of the steel plate are all realized by numerical control. High processing precision, especially the core components.

6. Sufficient supply of spare parts for worry-free operation

SBM business covers production and sales, and is responsible for every machine produced by itself. We can provide customers with product technical services and original spare parts to ensure that customers have no worries.

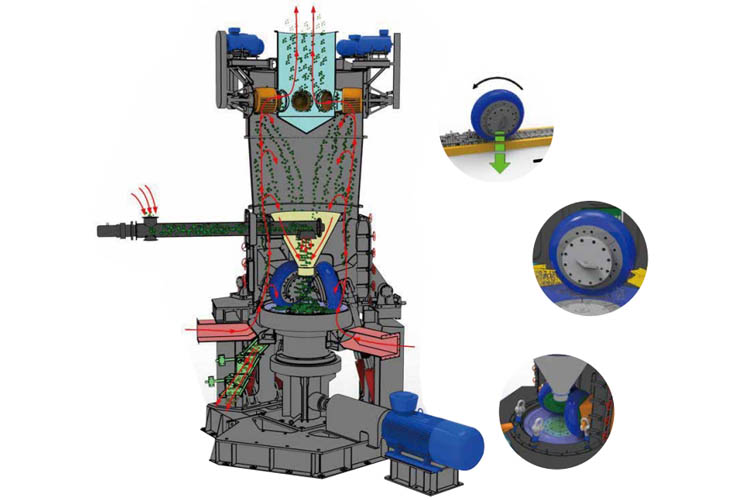

The ultrafine vertical mill is composed of several components, each of which plays a critical role in the operation of the machine. And they must work together in harmony to produce high-quality, ultra-fine powder. These components include: Grinding chamber, Agitator, Feed inlet, Discharge outlet, Motor, Control system, Cooling system.

Through spiral feeder, materials fall onto the center of grinding plate of calcium carbonate ultrafine powder vertical mill. Driven by the motor of host, the reducer rotates the grinding plate to form centrifugal force which forces materials to move towards the fringe of grinding plate.

While passing through the grinding area between roller and grinding plate, bulky materials are broken directly by the pressure of roller while fine materials form a layer where materials crush each other. Broken materials after grinding continue moving to the edge of grinding plate until they are brought away by the airflow and enter the powder selector.

Under the action of blades of selector, coarse particles which fail to meet standard of fineness drop to the grinding plate to have another grinding while powders meeting the standard enter the powder collector as finished products. For sundries like iron block in materials, when they move to the fringe of grinding plate, because of their heavier weight, they would drop to the lower cavity of grinding mill and next be sent into the discharging port by scarper installed at the bottom of grinding plate and finally be discharged out of the grinding mill.

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 6 | 6 | 8 |

| Power of classifier(Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power(Kw) | 180-200 | 250-280 | 325-355 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output(t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output(t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output(t/h) | 3-4 | / | / |

SBM Micropowder Technology Co., Ltd. located in PUDONG New district of Shanghai China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment. We have established a whole production chain. We still insist on communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always be on the industry front.

The main products include: ore stone crushers (jaw crushers, cone crushers, hammer crushers, etc.), ore grinding mills (ultrafine grinding mills, vertical mills, superfine wet mills, coarse powder mills, etc.), milling production line accessories (lifters, balers, silencers, dust bags, etc.), powder surface modifiers, etc.

If you want to know more information, you can leave us a message, our sales manager will get in touch with you later, looking forward to your inquiry.

Model: CLUM

Payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.