The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

22/07/2021 admin

Compared with dry ultrafine pulverization, because water itself has a certain degree of grinding aid effect, the powder is easy to disperse during wet pulverization, and the density of water is higher than that of air, which is conducive to fine classification. Therefore, the wet ultrafine pulverization process has the characteristics of high crushing efficiency, fine product particle size, and narrow particle size distribution.

Therefore, in terms of ultrafine grinding operations alone, wet processing is more efficient than dry processing, and the energy consumption per unit product is lower. In addition to colloidal mills and high-pressure jet mills, non-metallic ore wet ultra-fine pulverization mostly uses media grinding ultra-fine pulverization equipment such as stirring mills and sand mills.

Because the colloid mill and high-pressure jet mill process configuration are relatively simple, the following focuses on the introduction of the agitating mill, sand mill, and other media grinding ultra-fine grinding processes.

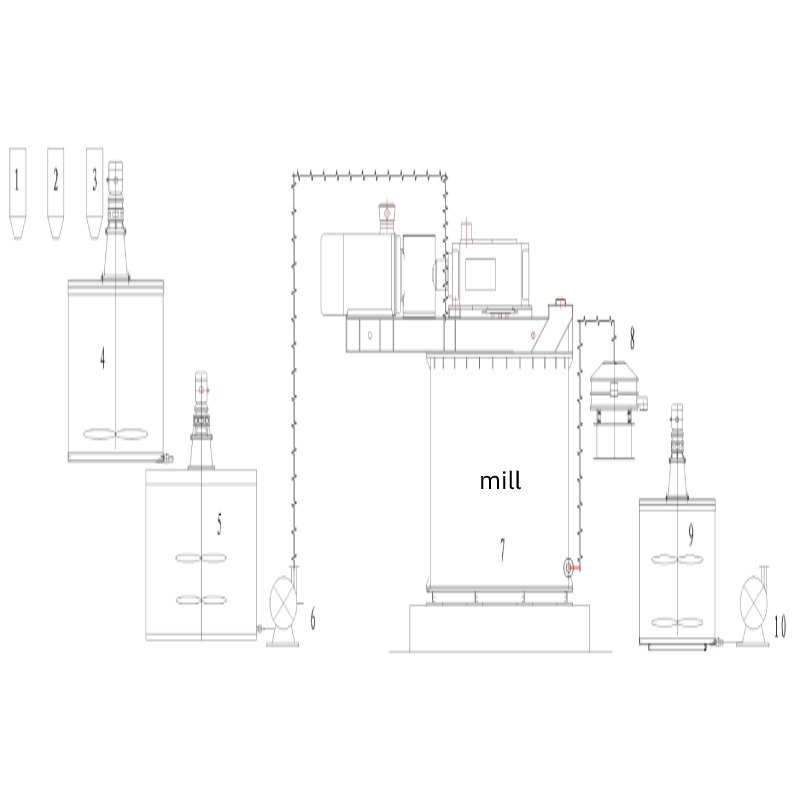

The ultrafine pulverization process of the wet stirring mill is mainly composed of the wet stirring mill and its corresponding slurry tank. The raw material (dry powder) is mixed into a slurry with a certain concentration or solid-to-liquid ratio by adding water and dispersant in the slurry tank and then fed into the slurry tank pumped into the stirring mill through the slurry tank for grinding. The number of grinding stages depends on the feed size and the requirements for product fineness.

One stirring mill (one-stage grinding) can be selected in practice, or two, three, or more stirring mills can be used for tandem grinding. The ground slurry enters the slurry tank and is concentrated after removing iron pollution and iron-containing impurities by a magnetic separator.

If the production line is built close to the user, it can be directly delivered to the user through a pipeline or tank. If it is far away, the concentrated slurry will be dried and dehydrated, and then depolymerized (particle agglomerates generated during the drying process) and packaging.

The main process factors that affect the ultra-fine pulverization of the wet stirring mill are the particle size and distribution of the raw materials, the density, diameter, and filling amount of the medium. The rotational speed or linear speed of the stirring mill. The residence time of the material in the stirring mill. The slurry concentration and the variety and dosage of the grinding aid or dispersant, etc.

(1) The density, diameter, and filling amount of the medium

The density and particle size of the medium affect the particle size of the product and the energy utilization rate of the mill. Studies have shown that when using a stirring mill to grind talc, the high-density zirconia balls (6.31g/cm3) have a higher crushing efficiency than the low-density glass balls (2.5g/cm3). At the same time, the small diameter glass ball (3 mm) has a better grinding effect than the large-diameter glass ball (5 mm). However, under certain product fineness requirements, the best medium density and medium diameter are related to the type of material to be ground, the size of the feed material, the slurry concentration, and the speed of the mill.

The filling amount of the medium influences the fineness of the product and the output. Within a certain range and under the premise of certain material throughput, an appropriate increase in the filling amount can increase the grinding strength and increase output and fineness. However, when the medium filling amount is too large, the energy consumption increases, and the energy utilization rate decreases.

(2) Rotating speed of the mill

The rotation speed or stirring speed of the mill greatly influences the fineness of the product, the output, and the energy utilization rate. The test on the horizontal stirring mill shows that increasing the stirring speed can increase the output of fine-grained grades.

The higher speed increases the proportion of fine-grained materials in the product. But from the perspective of energy utilization, it is not that the higher the speed, the better. Studies have shown that the input power of the mill increases with the increase in the speed of the mill, and the excessively high-speed results in a decrease in the energy utilization rate. The energy utilization rate is higher at a relatively low speed.

Therefore, the stirring speed of the stirring mill should not be too high. However, in the continuous pulverization process, too low agitation speed is likely to cause part of the materials to be discharged without sufficient grinding and pulverization, which makes the particle size distribution of the product coarser.

(3) Residence time of materials in the mill

When the equipment and other process conditions are constant, the residence time of the material in the mill has a significant impact on the fineness and output of the product. To ensure a certain product fineness, a certain residence time must be ensured. The residence time is related to the concentration of the slurry (or solid-liquid ratio), feeding speed, mill speed, height (vertical) or length (horizontal) of the mill barrel, and the degree of dispersion of materials.

Generally speaking, the longer the residence time of the material in the mill, the finer the product particle size, but the lower the output; on the contrary, the coarser the particle size will increase the output.

(4) Slurry concentration

In the ultra-fine grinding process of the stirring mill, the slurry concentration is a very important process parameter or a factor that affects the ultra-fine grinding effect and energy utilization rate.

Properly increasing the slurry concentration will help increase the quantity of -10μm granular materials and increase the energy utilization rate. However, as the slurry concentration increases, the viscosity of the system increases and the fluidity of the slurry deteriorates. The material to be ground is easy to adhere to the surface of the medium to weaken the grinding and impact of the medium on the material. Therefore, too high slurry concentration often leads to reduced pulverization efficiency and energy utilization, coarser product size, or reduced output.

The best slurry concentration is related to the medium density, diameter, required product fineness, grinding aids, material types and feed size, etc. It can be selected by referring to industrial production examples of similar materials or through experiments.

(5) Grinding aid or dispersant

Grinding aids or dispersants mainly affect or increase product fineness, output, or reduce unit product energy consumption by reducing the strength of granular materials, reducing the viscosity of the slurry, improving the dispersibility of the material, and promoting the fluidity of the slurry.

Generally speaking, only when the slurry concentration reaches a higher value can the dispersant be used to have a significant effect. That is, by adding a dispersant or grinding aid, the slurry concentration in the ultrafine grinding of the wet stirring mill can be increased.

The ultra-fine wet stirring mill can be used to grind calcium carbonate, soft and hard kaolin, coal water slurry, mica, barite, gypsum, rare earth, magnesium oxide, aluminum oxide, iron oxide red, and magnetic materials. The product fineness can reach the micron and sub-micron levels.

Sand mills are mainly used for wet grinding. Taking the horizontal sand mill as an example, the grinding process generally includes slurry preparation-dispersion (pretreatment)-grinding-sieve analysis, etc. According to the series of horizontal sand mills, it can be divided into one machine with one tank, one machine with two tanks, and multiple machines (more than 3 sand mills) in the series of ultra-fine grinding processes.

The slurry is circulated and ground in a sand mill and a storage tank until the fineness of the product meets the requirements. This technological process is simple, the equipment is small, the floor space is small, and the operation method is simple.

However, because the ground slurry returns to the storage tank and is easy to mix with the original slurry, and the existence of “dead corners” leads to an uneven particle size of the ground product, it is only suitable for occasions where the product particle size distribution is not strict.

The slurry is cyclically ground in one sand mill and two storage tanks. Although this process is more complicated than the one-machine-one-tank process, the cyclic grinding level is clear, and the product size is uniform.

The ultra-fine grinding process of continuous grinding with 3 closed sand mills and 2 storage tanks in series. In this process, the three sand mills connected in series use different speeds and grinding media respectively. From the first machine, it gradually decreases, and the discharge particle size is getting finer.

The three-machine series process can shorten the grinding time and improve the grinding efficiency; the grinding product has a fine and uniform particle size. However, there are more equipment and a larger area.

Process design and equipment selection principles

(1) Meet the product guidelines (product quality and quantity)

This is the first principle to be followed in process design and equipment selection. The product program includes quantity (annual output) and specifications (quality), and product quality requirements include product fineness (particle size and particle size distribution), particle shape, surface properties, and purity.

(2) Save investment

The amount of investment directly affects the future economic benefits of the factory. Therefore, under the premise of meeting the aforementioned design product guidelines, investment should be saved as much as possible. For process design, the equipment investment is the main component of the investment. Therefore, it is necessary to choose technology with less investment on the basis of meeting the product program and comparison of comprehensive performance indicators.

(3) Reduce energy consumption

Energy consumption is one of the most important production cost components of ultrafine powder processing plants, which directly affects the market competitiveness of future products and the economic benefits of enterprises. Therefore, on the basis of ensuring the product program and investment, comprehensive analysis, and comparison of benefits, it is necessary to select high-efficiency and low-energy-consumption equipment and simplify the process as much as possible to reduce the total installed capacity (total installed power) of the entire production line and reduce the unit product Energy consumption.

(4) Reduce wear

In the addition of ultrafine powder, the wear of crushing and classification equipment and the consumption of grinding media are inevitable. This attrition not only increases the production cost but also pollutes the material, resulting in a decrease in the purity of the pulverized material, which affects the quality of the final powder product. Therefore, in the design of ultra-fine grinding technology and equipment selection, attention must be paid to minimize the wear and grinding media consumption.

(5) Meet environmental protection laws and regulations

Environmental protection regulations and standards are mandatory, such as the Air Pollution Prevention and Control Law, the Water Pollution Prevention and Control Law, and the Noise Pollution Prevention and Control Law. Therefore, environmental protection measures must be taken in the design of the ultra-fine crushing process and equipment selection, otherwise, the only end is shutdown.

(6) Meet the requirements of labor safety and health regulations

Labor safety and hygiene regulations, such as building design fire protection codes and lightning protection codes, industrial enterprise design hygiene standards and lighting design standards, heating and ventilation, and air conditioning design codes, are also mandatory. Therefore, it must be considered at the same time in the design of the ultrafine grinding process and the selection of equipment.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.