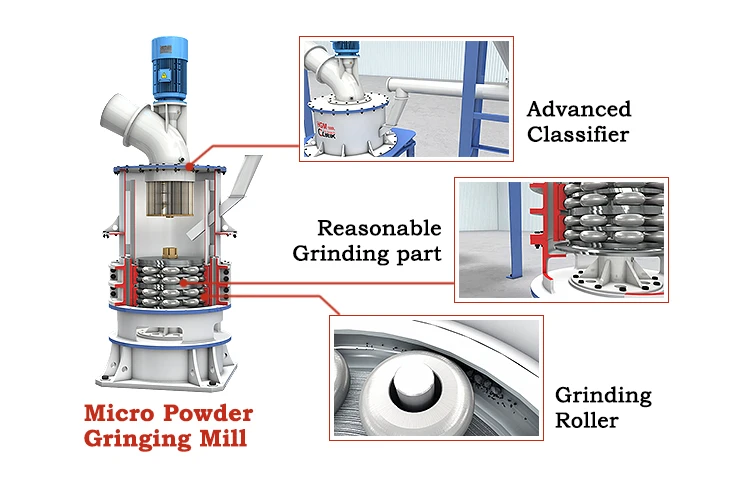

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Material: sulphoaluminate cement clinker, Portland cement, metakaolin, lime, gypsum, etc.

Feed particle size: <1mm

Moisture content: <5%

Purpose: Grouting and filling materials

Raw materials: sulphoaluminate cement clinker, Portland cement, metakaolin, lime, gypsum, etc.

Feed particle size: <1mm

Moisture content: <5%

Product use: Grouting and filling materials

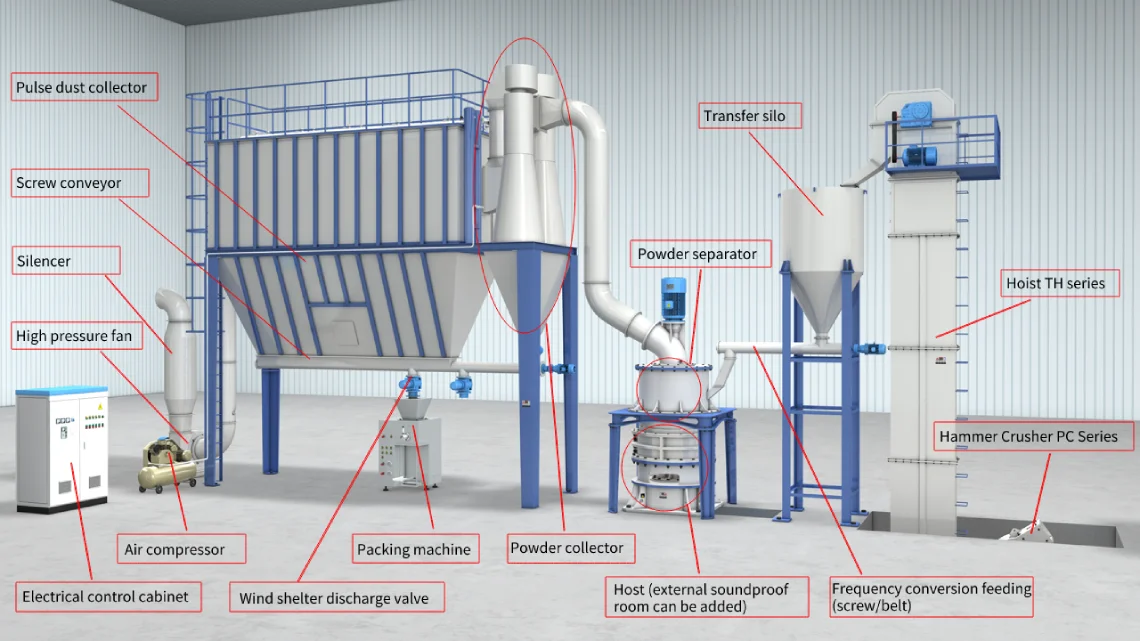

In this project, HGM1250 ultra-fine ring roller mill is used as the main equipment, and screw conveyor, powder packaging machine, pneumatic conveyor, etc. are used as auxiliary equipment. The whole set of anchoring agent production line can realize centralized control, automatic production, automatic troubleshooting and other processes in the production process, and has the advantages of simple operation and convenient maintenance.

Machinable materials: Non-flammable and explosive solid materials with Mohs hardness less than 7, such as marble, limestone, calcium carbonate, talc, barite and other non-metallic ores.

Output: 0.2-45t/h

Processing fineness: 150-3000 mesh, can be adjusted freely.

Advantages of the powder mill: small footprint, frequency conversion powder selection, high efficiency and energy saving, environmental protection and no pollution, simple operation, safe operation, continuous production for 24 hours without stopping, etc.

| Parameters of HGM series ultrafine mill | |||||||

|---|---|---|---|---|---|---|---|

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

The complete ring roller mill production line includes the crushing link (jaw crusher, cone crusher, etc., configured according to the characteristics and size of the material), the conveying link (screw conveyor, elevator, pneumatic conveyor, etc.), the grinding link (HGM Ultrafine mill, with powder classifier), powder collection link, packaging link and dust removal system, etc.

Our professional technicians will formulate the most suitable production line plan for customers according to the customer’s site environment and production needs and adapt measures to local conditions.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.