The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

10/10/2022 admin

The clay ultra-fine grinding mill adopts advanced grinding technology, which is more targeted and professional. It adopts a three-dimensional structure design and occupies a smaller area. It adopts a unique electrical centralized control system, and the finished product has high purity and uniform particle size.

As a ceramic raw material, clay has a complex mineral composition. It is mainly sandy clay composed of hydromica, kaolinite, montmorillonite, quartz and feldspar, and its color is often light gray, yellow, and purple. The clay has moderate water absorption, adsorption and water plasticity, good freeze-thaw resistance, light pollution resistance, good sound absorption, and strong air permeability and water permeability. At the same time, it has good weathering and corrosion resistance, good drying and sintering properties, and can be used as a raw material for pottery manufacturing. It is mainly used for firing pottery, earthenware, porcelain, floor tiles, and can also be used for exterior wall painting, and its application prospect is extremely impressive.

Uses of clay powder:

● Paper and coatings can replace some of the expensive titanium dioxide.

● Paints, water-based latex coatings.

● Rubber and special cable reinforcement, industrial plastic functional filler, ink, cosmetic filler.

● High whiteness porcelain and special ceramic raw materials.

● The clay has a strong suspending effect when used in pesticides.

In order to better realize the comprehensive utilization value of clay, it is necessary to grind it in depth. According to the characteristics and application of clay, we have developed and produced a clay grinder, which has extraordinary structure and performance advantages, and the price is particularly economical and quite affordable. It is liked by users and enjoys a good reputation in domestic and foreign markets.

Ceramic milling processes can be roughly divided into two types: wet and dry. Compared with wet production, dry production saves more than 80% of thermal energy consumption, more than 35% of electricity consumption, more than 80% of emissions, and also saves additives such as water-reducing agent and ball stone. In addition, the wet method is gradually eliminated due to the pressure of environmental protection.

Clay ultra-fine grinding mill + granulator

Mainly, the ceramic raw materials are directly ground with a mill, then humidified and granulated with a dry granulator, and then dried with a fluidized bed to control the moisture content of the powder at 7%, and then enter the compression molding process. The drying time is short, the drying is fast, and the output is high.

Ball mill wet mill + dryer

The ceramic raw material is transported to the ball mill, and then 30~40% water is added to grind it into a slurry, and then dried in a drying tower to make a powder with a moisture content of 7%. The drying time is long, the drying is slow, and the yield is low.

The clay grinding process is generally divided into three types of clay coarse powder processing (0-3MM), fine powder processing (20 mesh-400 mesh), and ultra-fine powder processing of clay (400 mesh-3250 mesh).

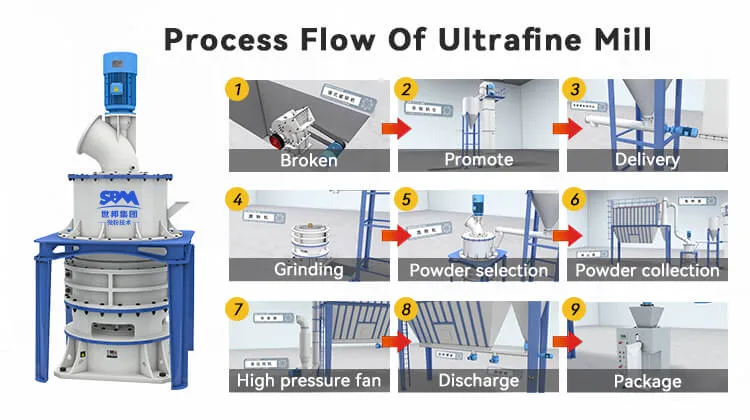

Stage 1: Broken

The large pieces of clay are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

Stage 2: Grinding

The crushed small pieces of clay are sent to the silo by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the vibrating feeder for grinding.

Raymond mill and YGM high pressure mill are generally used for fine powder processing; CLUM ultra-fine vertical mill and HGM ring roller micro-powder mill is generally used for superfine powder processing; European version coarse powder mill is used for coarse powder processing.

It can grind solid materials with Mohs hardness less than 9, and the fineness of finished products can be adjusted directly and freely between 80-600 mesh.

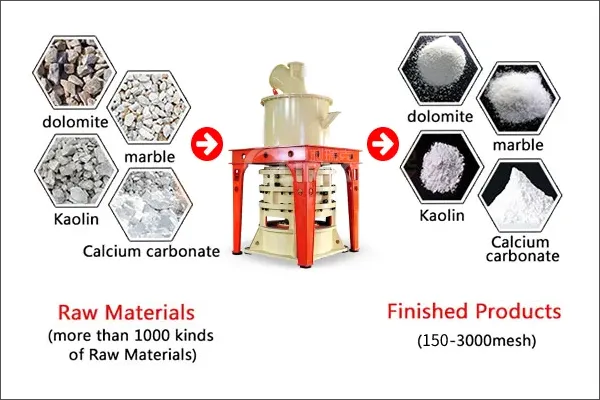

It can grind non-metallic ores with Mohs hardness less than 7, and the fineness of finished products can be freely adjusted between 150-2500 mesh. Small footprint, high efficiency and low consumption, environmental protection and no dust pollution…

It can grind non-metallic ores with Mohs hardness less than 7, and the fineness of finished products can be freely adjusted between 300-3000 mesh. Large output, high powder purity, energy saving and environmental protection…

Stage 3: Grading

The pulverized material is classified by the powder separator, and the unqualified powder is classified by the powder separator and then returned to the main engine for re-grinding.

Stage 4: Gathering Powder

The powder that meets the fineness enters the dust collector through the pipeline with the airflow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is uniformly packed by a powder tanker or an automatic baler.

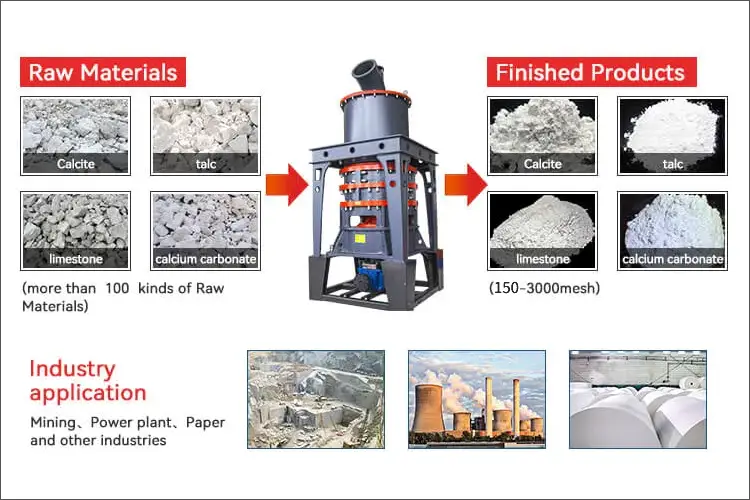

It is mainly suitable for non-flammable and explosive materials such as calcite, calcium carbonate, dolomite and talc with Mohs hardness below 7 and humidity below 6%.

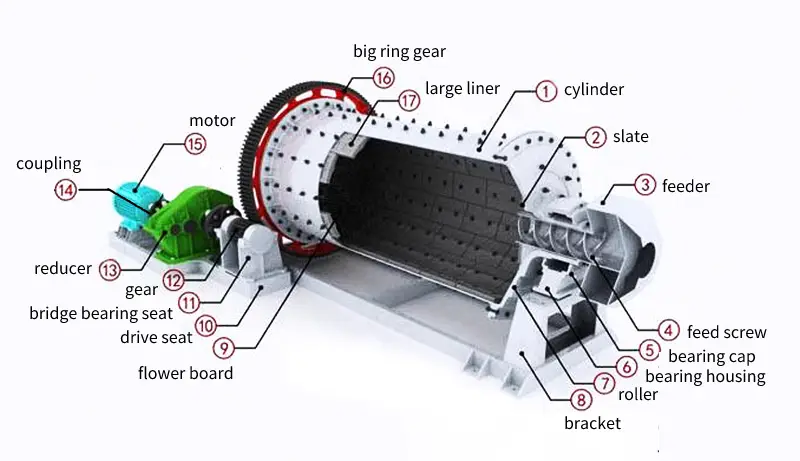

The complete set of equipment includes hammer crusher, bucket elevator, storage bin, electromagnetic vibrating feeder, main engine, powder separator, diffusion double cyclone powder collector, pulse dust collector, high pressure fan, and muffler.

● Stable, reliable and environmentally friendly

There are no rolling bearings and screws in the grinding chamber, which avoids the problems that the bearings are easily damaged and the screws are loosened and the equipment is damaged. The equipment adopts pulse dust collector, equipped with muffler and muffler room, which reduces dust and noise pollution and has good environmental protection effect.

● Low loss and high fineness

Wear parts are made of wear-resistant materials, with a service life of more than one year, and the final fineness of the finished product can reach D97≤5μm at one time.

● Low investment and high efficiency

Wear parts are made of wear-resistant materials, with a service life of more than one year, and the final fineness of the finished product can reach D97≤5μm at one time.

The motor of the main engine drives the main shaft and each layer of turntables to rotate through the reducer, and the turntable drives dozens of ring rollers to roll and rotate in the grinding ring raceway through the pin.

The bulk material is crushed into small particles by the crusher and then sent to the storage bin by the elevator, and the electromagnetic vibrating feeder evenly sends the material to the middle of the upper turntable. Under the action of centrifugal force, the material is scattered to the periphery of the circle and falls into the raceway of the grinding ring to be punched, rolled, ground and pulverized by the ring roller. After the first layer is pulverized, the material falls into the second and third layers.

The suction effect of the high-pressure centrifugal fan sucks the outside air into the machine and brings the coarse powder after the third layer pulverization into the classifier. The vortex flow generated by the rotating worm wheel in the powder separator makes the coarse particles fall back for regrinding, and the fine powder enters the cyclone powder collector with the airflow and is discharged from the discharge valve at the lower part. The airflow with a small amount of fine dust is purified by the pulse dust collector and discharged through the fan and the muffler.

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

How to choose the right model?

There are 5 models of HGM series ultra-fine grinding mills. The following video explains how to choose the most suitable ultra-fine mill for your production line.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.