The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 1-300 μm

Feed size: <10mm

Output: 10-5000 kg/h

Product features: Innovative Design, Adjustable Fineness, Cooling System, Ease of Maintenance, High Efficiency Transmission, Superior Quality

The CLQM series Airflow Vortex Mill Powder Micronizer is designed for processing a wide range of materials, offering uniform particle sizes that can be adjusted according to specific requirements.

The CLQM airflow vortex mill powder micronizer is capable of grinding materials to micron and sub-micron levels, making it highly versatile and suitable for processing difficult-to-handle materials.

This flexibility enhances the quality and added value of the final product, leading to significant economic benefits.

The CLQM Vortex Mill is suitable for a variety of industries including chemical, mineral, pharmaceutical, tobacco, food, feed, pigment, dye, coating, pesticide, metallurgy, ceramics, glass glazing, marine products, inorganic salts, cellulose, biotechnology, and plastics (such as PS, EPS, XPS). It is particularly effective for materials with low to medium hardness.

The CLQM vortex mill is a vertical shaft impact mill equipped with a classification system within the grinding chamber. After grinding, the materials are collected through the classification system, which replaces traditional screens, allowing the machine to perform both micronization and classification in a single step. This design enhances grinding efficiency.

CLQM airflow vortex mill equipped with an airflow regulator and a stepless speed controller for the classifier wheel, the fineness of the output can be adjusted without stopping the machine. Fine powders are fully recoverable, reducing environmental pollution.

The CLQM vortex mill features air cooling to maintain low temperatures during grinding, making it ideal for heat-sensitive and fibrous materials. For special requirements, advanced water or cold air cooling systems can be added.

The CLQM vortex mill is designed for easy operation, cleaning, and maintenance, and offers high production capacity.

Utilizing a narrow V-belt drive system, the CLQM vortex mill delivers high transmission power, smooth operation, and high working efficiency.

The use of durable bearings and balanced components ensures the quality and durability of the machine. It can be installed on a flat cement floor or supported by vibration pads without the need for a foundation.

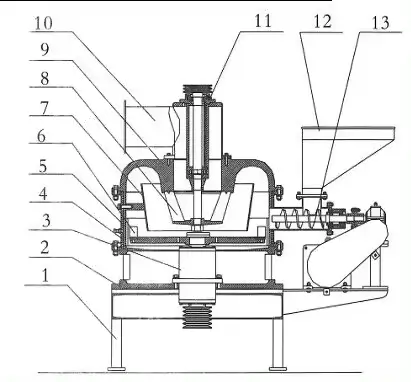

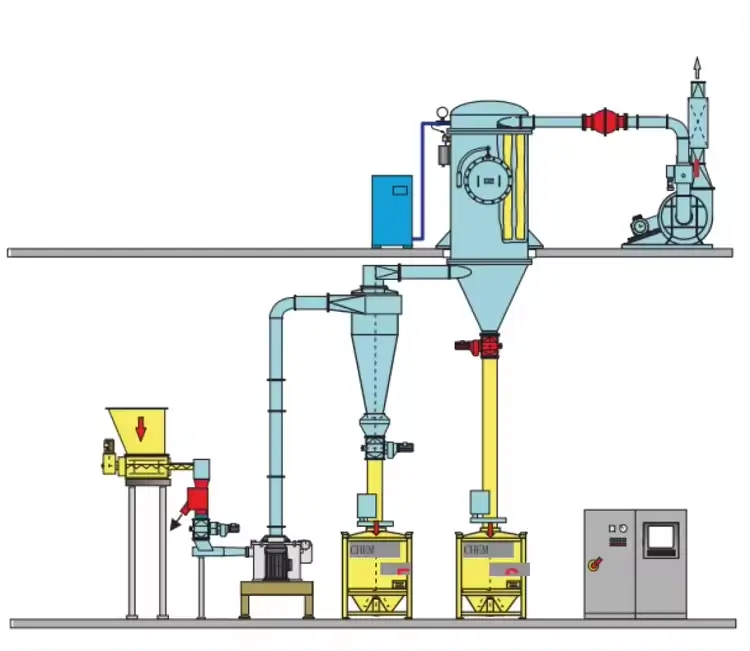

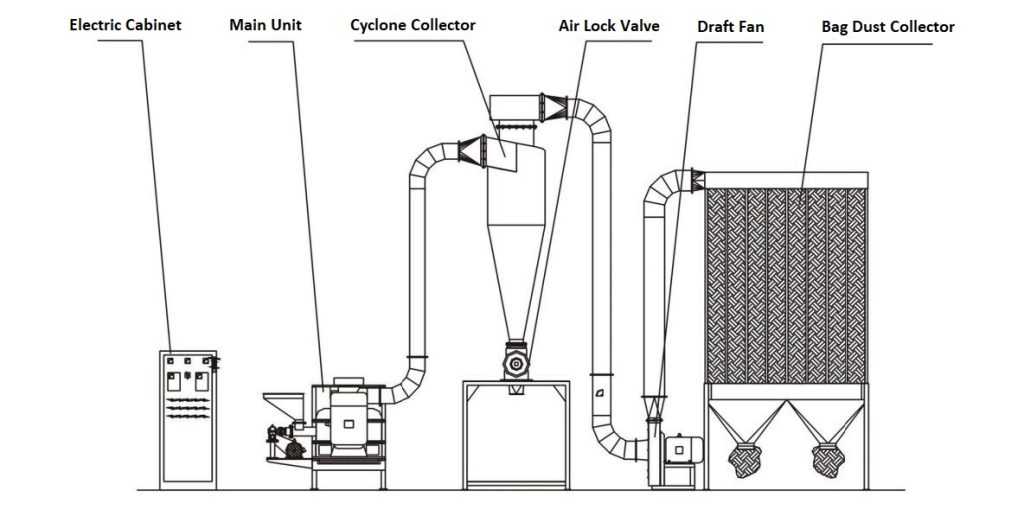

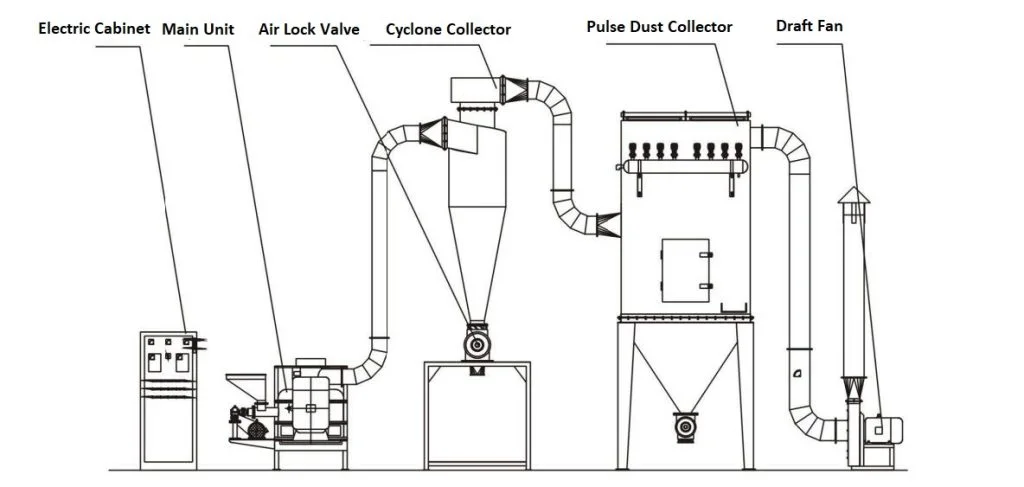

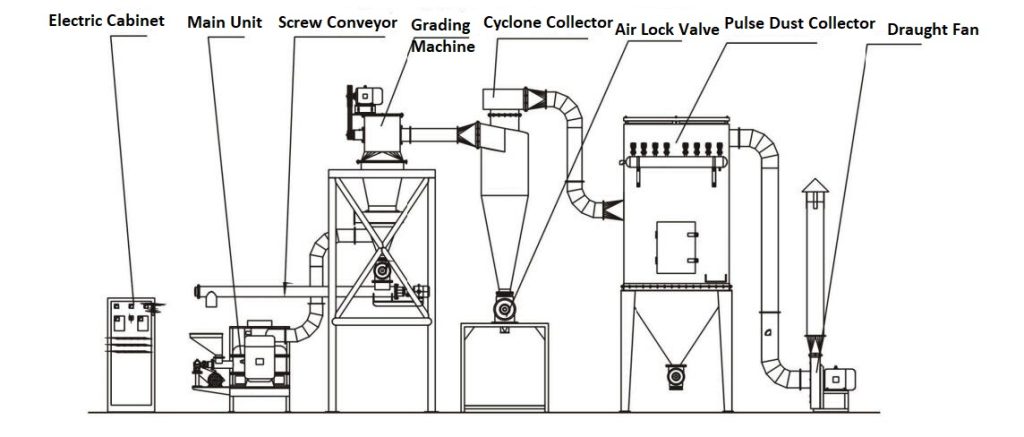

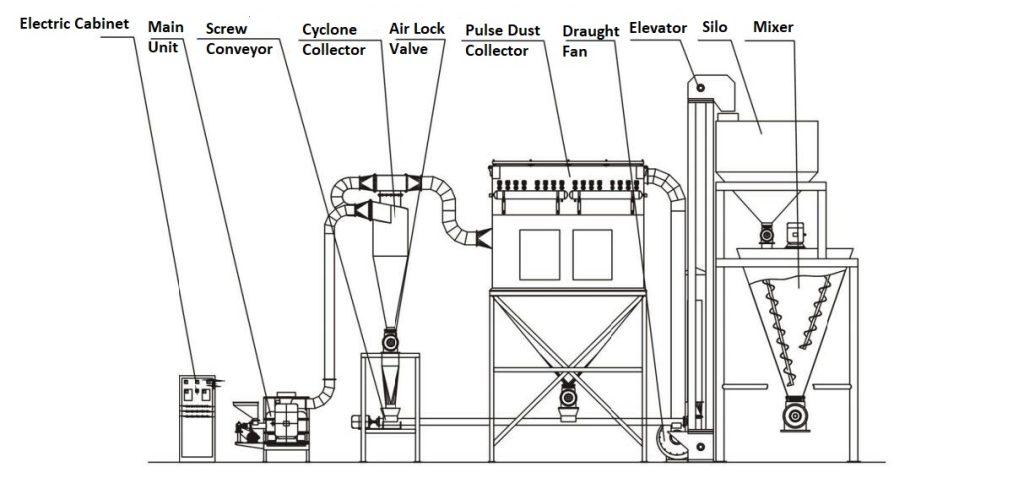

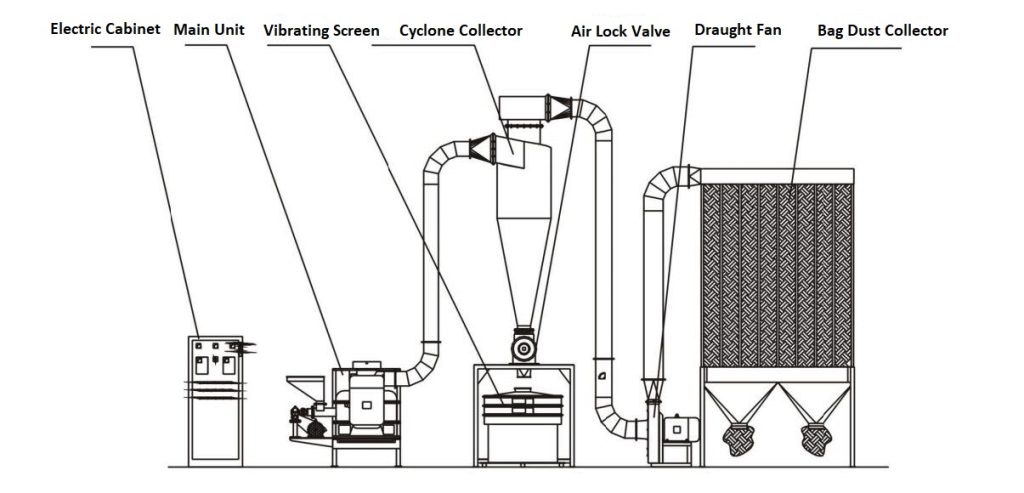

The machine comprises a body, frame, feeding device, grinding unit, discharge pipe, transmission system, and motor. The internal structure includes a main machine, dust collector, high-pressure centrifugal fan, rotary valve, cyclone separator, and electrical control cabinet.

The inner chamber of the machine is cylindrical, divided into two parts by an annular plate: the lower part serves as the air intake chamber, and the upper part, separated by a deflector ring, contains the grinding and classification chambers.

The grinding chamber consists of a grinding disc and stator, which pulverize the material into fine powder.

The classification chamber, equipped with a classifier wheel, separates the fine powder into two categories: those that meet the required fineness are collected through the discharge pipe and cyclone separator, while the others are recirculated for further grinding until they meet the standards.

Both the grinding disc and classifier wheel are driven by separate shafts and motors, allowing the classifier wheel speed to be adjusted to produce products of varying fineness.

The feed screw, located on the side of the machine, feeds material into the grinding chamber, and its speed can also be adjusted to match different feeding rates.

If needed, the main machine can be equipped with a speed adjustment device to meet more stringent grinding requirements.

The machine typically includes a simple dust collector to complete the process from grinding to dust collection.

However, for ultrafine powders and high-value materials, a pulse dust collector is recommended. This system uses a cyclone separator to separate dust-laden air, allowing larger particles to settle in the dust hopper.

The remaining dust is trapped on the outer surface of filter bags, while clean air exits through the outlet.

A pulse controller periodically releases compressed air to shake off the accumulated dust from the filter bags, ensuring efficient dust removal and maintaining optimal airflow.

As an excellent manufacturer of ore grinding equipment in China, we focus on the field of non-metallic ore ultrafine powder, constantly update and improve equipment, pursue the ultimate, and create higher value for customers.

Help customers to select equipment

Free arrangement of engineers to the site for actual survey and plan design

Strict implementation of quality standards, quality assurance of ex-factory products

Free logistics and transportation information, more choices for logistics and transportation

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

Free arrangements for engineers to guide the basic production of equipment

Provide free technical guidance for equipment installation and commissioning

The free on-site one-to-one operation, repair, maintenance, and other training

Professional after-sales service team, 24 hours response to customer needs

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

CE, ISO9001

factory sell directly

30 years experience, professional

Parameter 1

| Model | Motor(kw) | Rotated Speed(rpm) | ||||

| Main Unit | Classifier | Feeder | Main Unit | Classifier | Feeder | |

| CLQM-15 | 7.5 | 0.75 | 0.55 | 7000 | 800-3000 | 20-100 |

| CLQM-20 | 11 | 1.1 | 0.55 | 5500 | 750-3100 | 20-100 |

| CLQM-30 | 22 | 4 | 0.55 | 4000 | 700-2800 | 20-100 |

| CLQM-45 | 30 | 5.5 | 0.55 | 3500 | 650-2600 | 20-100 |

| CLQM-60 | 45 | 7.5 | 0.55 | 3000 | 600-2400 | 20-100 |

| CLQM-100 | 55-75 | 11 | 1.1 | 2000 | 500-2000 | 20-100 |

| CLQM-125 | 90-110 | 15 | 1.1 | 1600 | 400-1600 | 20-100 |

Parameter 2

| Model | Diameter of rotor disc (mm) | Diameter of gear ring (mm) | Diameter of classifier (mm) | Linear speed of the outermost end of the rotor disc (m/s) | Air volume (m³/h)(max) | Product fineness (μm) | Output (kg/h) | Main Unit Dimension (L*W*H mm) |

| CLQM-15 | 300 | 366 | 175 | 110 | 700-1200 | 3-300 | 10-200 | 1450*900*1000 |

| CLQM-20 | 300 | 366 | 175 | 87 | 1300-2800 | 5-300 | 20-600 | 1450*900*1000 |

| CLQM-30 | 400 | 470 | 242 | 84 | 2200-3600 | 5-300 | 30-1000 | 1740*1190*1100 |

| CLQM-45 | 550 | 601 | 274 | 102 | 3600-6500 | 10-300 | 40-1200 | 1940*1250*1170 |

| CLQM-60 | 700 | 774 | 350 | 110 | 4000-7500 | 10-300 | 50-1500 | 2150*1460*1380 |

| CLQM-100 | 1000 | 1080 | 414 | 106 | 8000-12000 | 10-300 | 80-3000 | 2840*2150*1760 |

| CLQM-125 | 2000 | 1295 | 461 | 101 | 12000-16000 | 10-300 | 120-5000 | 3000*2380*2000 |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.