Raymond mill is a high-efficiency pulverizing mill that replaces ball mill to process ore powder.It has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance.

Discharge fineness: 80-500 mesh

Feed size: <35 mm

Output: 1-35 t/h

Materials: Quartz, feldspar, barite, carbonate calcite, limestone, talc, ceramics, iron ore, emery, bauxite, phosphate rock, coal and other materials, a total of about 400 kinds of materials

Product features: Raymond mill has a small footprint, environmental protection and energy saving. The production of the production has fine texture, uniform particles, less impurities, and the screening rate is as high as 99%

CLRM series Raymond mill is suitable for processing various non-flammable and non-explosive mineral materials with Mohs hardness less than 6 and humidity less than 6%. It is widely used in metallurgy, construction, chemical industry, mining, highway construction and other fields. The particle size of the finished powder can be adjusted between 50-325 mesh (315-45 microns). The materials that can be processed by this type of Raymond mill include quartz, feldspar, barite, carbonate calcite, limestone, talc, ceramics, iron ore, emery, bauxite, phosphate rock, coal and other materials, a total of about 400 kinds of material.

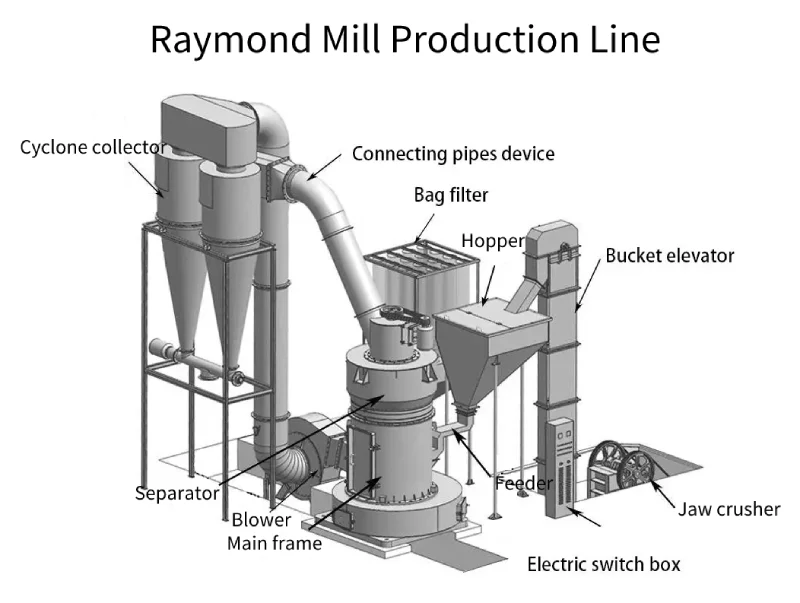

The standard configuration of CLRM enhanced Raymond mill is composed of main engine, reducer, powder separator, cyclone powder collector, dust collector, blower, electric control cabinet and link pipes. Optional accessories include crusher, bucket elevator, feeder.

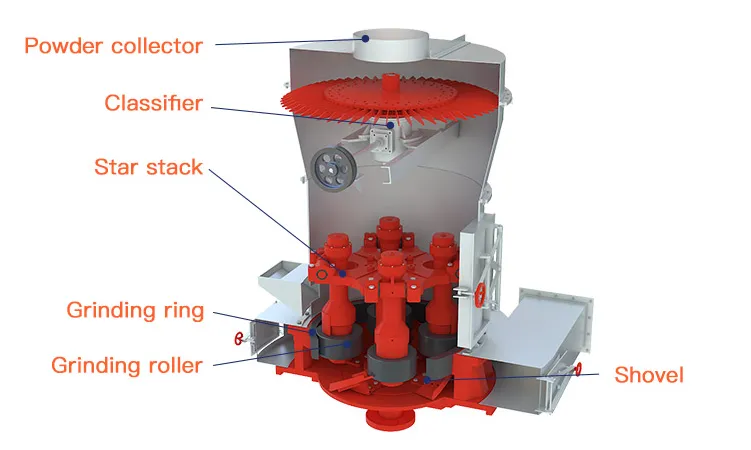

● Optimize the grinding part and improve the grinding efficiency

Compared with the previous generation mill, the grinding pressure is increased by 10% and the grinding area is increased by 15-20%. The layout of the grinding rollers has been optimized to increase the sufficient grinding space.

● Triple vibration damping ensures working stability

Triple damping to resist the vibration transmission of the main engine base, the volute airflow chamber, the unit body, and the grinding part. Make sure the grinding condition is stable.

● New frequency conversion grinder impeller

Equipped with a new cage type wire drawing machine impeller, frequency conversion speed regulation, the output size range is expanded to 80-425 mesh.

● The grinding device adopts superimposed multi-stage seals to prolong the lubrication cycle.

After being crushed by the jaw crusher to the required particle size, the bulk materials are transported to the storage hopper by the bucket elevator, and then evenly and continuously fed into the main grinding chamber by the vibrating feeder for grinding.

The pulverized fine powder is carried by the air flow of the blower to the classifier for classification. The powder that meets the fineness enters the cyclone collector through the pipeline, where it is separated and collected, and discharged at the discharge valve to become the finished product.

Air is drawn into the blower by a return duct at the top of the cyclone collector. The entire airflow system of the machine is sealed and circulated under positive and negative air pressure.

| Model | Roller | Ring | Main Shaft Speed(r/min) | Feeding Size(mm) | Finished fineness (Mesh) |

Motor(kw) | Capacity(t/h) | ||

|---|---|---|---|---|---|---|---|---|---|

| Qty(pcs) | Size(mm) | External Dia(mm) | Height(mm) | ||||||

| CLRM9720 | 3-4 | Φ320*200 | 1077 | 200 | 145 | <20 | 80-500 | 45*15*37 | 1-7 |

| CLRM1280 | 3 | Φ370*240 | 1280 | 240 | 125 | <20 | 80-400 | 75*15*55 | 2-12 |

| CLRM1300 | 4 | Φ410*280 | 1390 | 280 | 112 | <20 | 80-400 | 110*22*90 | 3-15 |

| CLRM1620 | 4 | Φ450*300 | 1620 | 300 | 102 | <20 | 80-400 | 160*30*132 | 5-20 |

| CLRM1700A | 4 | Φ510*300 | 1700 | 300 | 102 | <30 | 80-325 | 185*37*160 | 6-25 |

| CLRM1720 | 4 | Φ510*300 | 1850 | 300 | 92 | <35 | 80-325 | 250*45*185 | 6-25 |

| CLRM1900A | 4 | Φ600*300 | 1900 | 300 | 92 | <35 | 80-325 | 250*45*220 | 8-32 |

| CLRM2150 | 4 | Φ600*300 | 2150 | 300 | 85 | <35 | 80-325 | 315*45*280 | 12-35 |

Note: For the motor data in the above sheet such as “45*15*37″ means the main motor * classifier motor * blower motor

SBM Micropowder Technology Co., Ltd. located in Pudong New district of Shanghai, China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment.

So far, we have established a whole production chain. The products cover micro powder grinding mill, high pressure grinding mill, Europe a version coarse grinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on.

In particular, we independently developed HGM micro powder grinding mill, which are not only renowned in the domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.