The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <15 mm

Output: 1-20 T/H

Product features: Higher capacity, better powder quality, more excellent comprehensive performances

CLUM series of ultrafine vertical grinding mills are a new type of ultra-fine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying.

It has high grinding efficiency, low energy consumption, uniform particle shape, narrow particle size distribution, good fluidity, and strong product adaptability. It is an ideal non-metallic ores powder making equipment.

01

The finished powder has strong diversity and high added value

The main machine is equipped with a high-efficiency multi-rotor powder concentrator, the finished product has a wide range of particle size, 2um powder content up to 70%, D97=4-5um, specific surface area 21000cm2/g, the main machine powder can reach D97=8.5um for two times The powder selection system can choose 4-5um powder.

The finished powder has a narrow particle size distribution, adjustable 2um content, good particle shape, and high added value of the finished product.

02

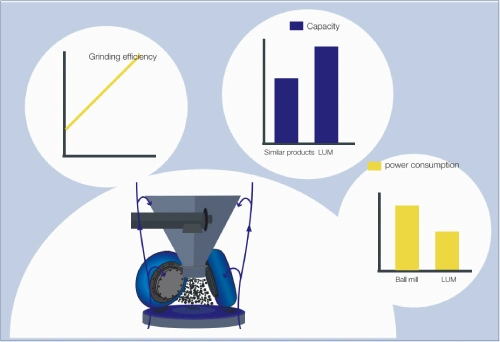

High grinding efficiency and low power consumption

The optimized design of grinding rollers, grinding discs and internal airflow guidance greatly improves the grinding efficiency. The productivity is 30% higher than similar products, and the power consumption is 30%-60% lower than that of the ball mill.

03

Intelligent control system, stable and efficient operation

The internal uses PLC intelligent control, the external uses the touch screen to display and adjust the system parameters in real time. Modular excuses are reserved, and the scalability is strong, which can quickly realize the connection of the front-end grinding aid adding system, the back-end powder modification system and the packaging system to ensure the automatic control of the entire process.

04

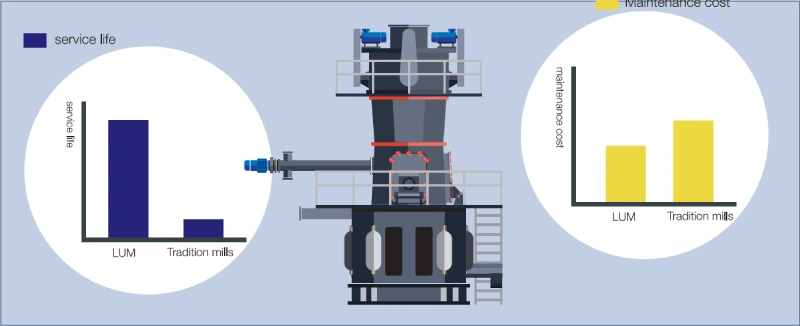

Long service life and low maintenance cost

The wear-resistant parts of the main engine are made of high-wear-resistant synthetic steel, which effectively prolongs the service life of the wear-resistant parts, reduces the iron content of the finished product, and reduces maintenance costs.

05

Green

Environmental protection

With the new structure design and the principle of grinding, the equipment has low vibration and low noise.

The equipment is sealed as a whole, the system works under negative pressure, and the dust points are controlled by pulse dust collectors, no dust spills, and environmentally friendly and clean.

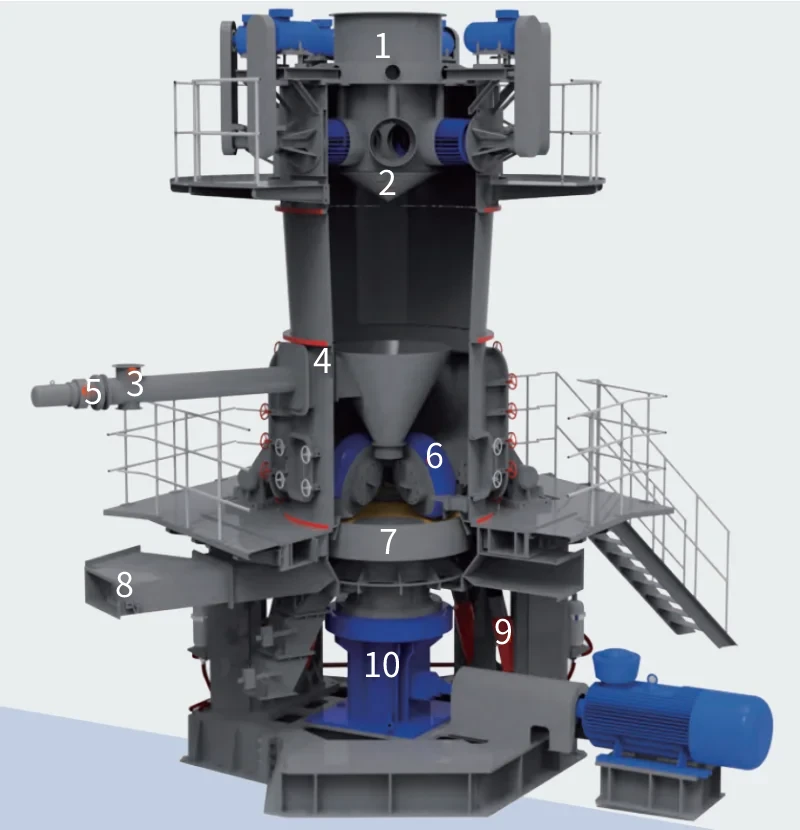

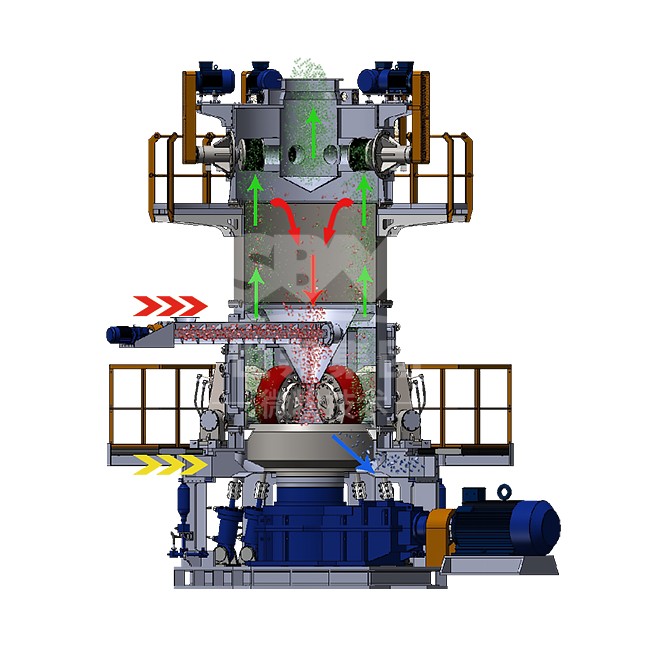

The main engine of CLUM ultrafine vertical grinding mill is mainly composed of motor, reducer, machine body, grinding roller device, grinding disc device, pressurizing device, powder separator, lubricating station, hydraulic station, etc.

1 Finished product discharge port

2 Powder concentrator

3 Inlet

4 middle body

5 Screw conveyor

6 Grinding roller assembly

7 Grinding disc assembly

8 Air inlet

9 Working hydraulic cylinder

10 Motor and reducer

Grinding rollers and discs are made of highly wear-resistant materials, with long service life and low maintenance costs

The grinding zone between the grinding roller and the grinding disc adopts a special grinding curve design to ensure the stable operation of the host and effective grinding

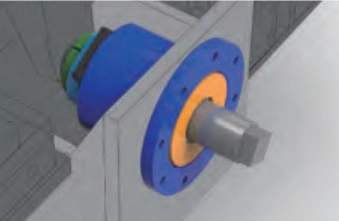

The pressure of the grinding roller adopts a hydraulic tension rod with adjustable elastic coefficient to ensure the continuous pressure of the grinding roller on the material

The grinding roller and the grinding disc are not in contact, and the mechanical limit device is adopted to avoid damage, impact and vibration

The multi-rotor high-efficiency cage powder separator has high powder separation efficiency and is easy to adjust and control, and can quickly produce a variety of finished products

The main motor drives the grinding disc to rotate through the reducer.

The materials fall into the center of the grinding disc through the elevator, screw conveyor, star-shaped feeding valve, and feeding screw, and move to the edge of the grinding disc under the action of centrifugal force. When passing through the grinding zone between the grinding roller and the grinding disc, it is crushed by the pressure of the grinding roller and the shearing force between the grinding disc and the grinding roller.

The pulverized material continues to move to the edge of the grinding disc until it is brought into the multi-rotor powder concentrator at high speed by the airflow from the high-pressure fan on the edge of the grinding disc for classification.

The powder that does not meet the requirements falls into the grinding disc and re-grinds. The powder that meets the requirements is collected by the airflow into the dust collector, and sent to the finished product warehouse by the lifting system or the pneumatic conveying system.

MORE>>

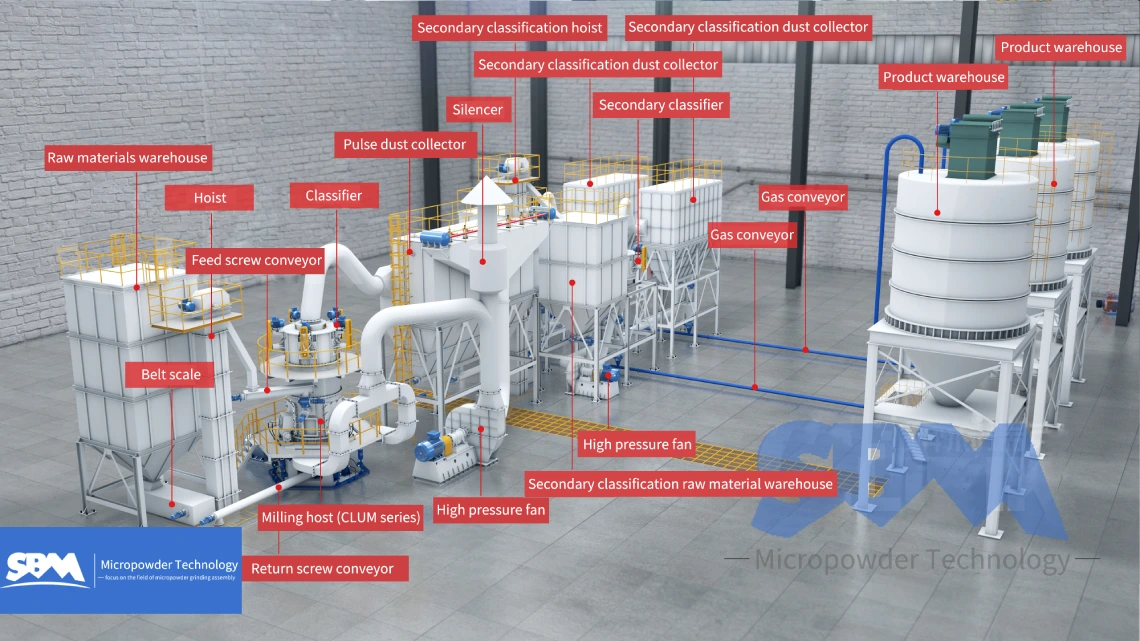

Ultrafine vertical grinding mill stone powder production line

CLUM vertical roller mill working principle

| Product name | Product performance | Equipment performance |

|---|---|---|

| Raymond mill | 2um content is about 6% or more, the highest fineness is 45um, low-end finished powder. | Production of coarse powder and general fine powder above 45um, stable operation, high cost performance and high noise. |

| Ring roller mill | 2um content is about 20% or more, the highest fineness is 8-10um, middle and high-end finished powder. | Produce 10-15um powder, stable operation, short life of wearing parts, high noise and low output. |

| Ball mill | Generally produce 45um thick body; ultra-fine ball mill can produce 10um powder; ceramic ball mill has high whiteness and the lowest iron content. Good grain, spherical. |

It is suitable for a wide range of materials, a wide range of particle size of the finished product, a wide selection of grinding media, high energy consumption and high noise. Producing different specifications of powder, long switching time. Difficulty in fineness adjustment. |

| Jet mill | 5um powder can be produced, jet pulverization, the whiteness of the finished powder is the best. High-end food grade finished powder. |

Mechanically crushed, the powder has the highest fineness. It is only suitable for high-end or high value-added powders. High energy consumption and low output. |

| Ultrafine vertical grinding mill | The content of 2um is 30%-70%, D97=4-45um, the fineness of powder can reach 8.5um at one time, and the specific surface area is high | There is no contact between the roller and disc, the vibration is small, and the operation is stable. Low energy consumption and large output. The production of finished products of different specifications can realize rapid switching. The products are highly professional, and the initial investment is relatively large. |

| One-time pulverizing system | Mainly include raw material crushing, raw material transportation, ultra-fine grinding and grading, finished product collection, finished product transportation, finished product storage, and auxiliary equipment |

|---|---|

| Raw material | crushing, jaw crushing, hammer crushing, etc. |

| Raw material conveying | hoists, belt scales, buffer bins, star-shaped feeding valves, screw conveyors, etc. |

| Superfine grinding and classification | Superfine vertical grinding mill main machine and multi-rotor powder separator |

| Finished product collection | Air box pulse bag filter |

| Finished product conveying | screw conveyor, discharge valve, hoist or pneumatic conveying system, etc. |

| Finished product storage | Finished product tank |

| Auxiliary equipment | grinding aid adding system, cooling water system, compressed air system, iron remover, etc. |

| Secondary powder selection system | Mainly composed of multi-rotor ultra-fine powder separator, fan, pulse dust collector, hoist, discharge valve, screw conveyor and finished product tank, etc. |

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Working Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 6 | 6 | 6 |

| Power of classifier (Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power (Kw) | 180-200 | 250-280 | 325-410 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output (t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output (t/h) | 3-4 | / | / |

Material: base on calcite

Particle size distribution: measured by microlayer diffraction particle size analyzer in British Malvern 3000 instruments

Pre-sale

On-sale

After-sale

Free to help customers in equipment selection and scheme design.

You are always welcomed to visit SBM! Visit our prototype and showroom.

Strictly implement quality standards, and guarantee the quality of products shipped.

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery.

Overseas professional installation team provides technical guidance for equipment installation and commissioning.

Train the start-up process, teardown method, common problems and maintenance service.

Professional after-sales service team, 24 hours response to customer needs.

Model: CLUM

Payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.