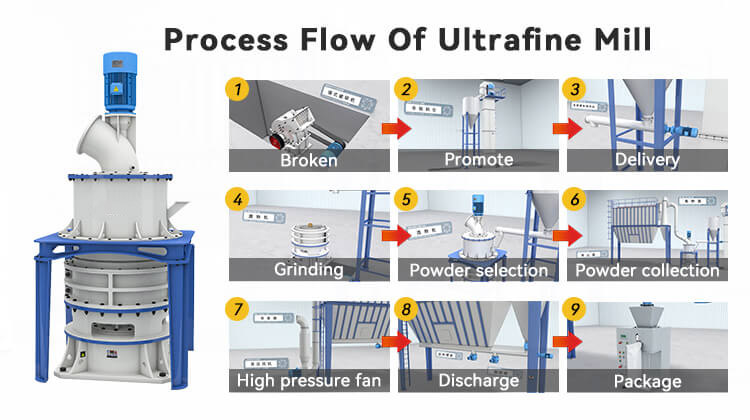

Step 1: Raw Material Preparation:

Cleaned and dried conch shells are first crushed into smaller pieces using a jaw crusher or hammer mill.

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

07/03/2025 admin

The HGM Ultrafine Mill is an excellent conch powder making machine, known for its ability to grind materials to an ultrafine particle size, making it ideal for various applications.

Cleaned and dried conch shells are first crushed into smaller pieces using a jaw crusher or hammer mill.

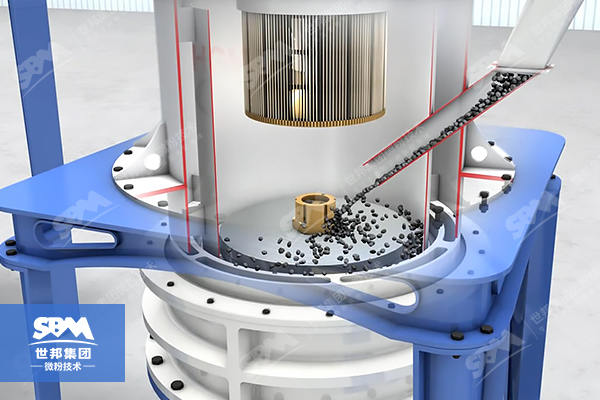

The crushed conch shell material is fed into the HGM Ultrafine Mill, where it is subjected to mechanical forces that reduce particle size.

The mill uses mechanical forces to achieve ultrafine particle sizes.

A classifier separates the ultrafine powder from coarser particles. The finer material is collected, while the coarser particles are returned for further grinding.

The mill includes a dust collection system to ensure a clean working environment and prevent material loss.

The conch powder ground by the HGM ultrafine mill can be widely used in many fields:

In a recent customer reception, we had the honor to serve a customer who had special needs for shell and conch processing.

The customer wanted to process the conch into 1000 mesh fine powder to meet its application needs in multiple industrial fields such as rubber, plastics, coatings and papermaking.

In order to achieve this goal, we arranged a trial run of the HGM80 ultrafine mill and achieved satisfactory results.

At the trial run site, we demonstrated the high efficiency and superiority of the HGM80 ultrafine mill.

The equipment has excellent grinding technology and can grind shell materials into 1000 mesh fine powder.

After a series of experiments and adjustments, we finally obtained the fineness and output required by the customer.

The customer was very satisfied with the results of the trial run and believed that the HGM80 mill fully met its processing needs.

Considering the customer’s production needs and expected output, we decided to configure the HGM125 mill for it.

The HGM125 ultrafine mill is not only more advanced in technology, but also has a processing capacity of up to 15 tons per hour.

This output not only meets the customer’s requirements for production efficiency, but also ensures the high quality of the product.

The processed 1000 mesh shell and conch powder will be widely used in many industries such as rubber, plastics, coatings and papermaking.

As a high-quality filler, shell powder can improve the performance and appearance of the product and has good market prospects and economic benefits.

Through this successful trial and equipment configuration, we have once again proved the strong strength of HGM ultrafine grinding mill in the field of conch processing.

We look forward to further cooperation with customers to help them achieve their production goals and contribute to the market expansion of shell and conch powder.

If you are also interested in conch powder making machine, please contact us for more information!

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.