The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Output Size: 3-100mm

Feed size: <300mm

Capacity: 27-1400t/h

Application: Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganeseore, refractory material, glass, etc.

Cone crusher is suitable for cement mill, mining, construction, road and bridge, railway, metallurgy, and other industries. It can be used to crush hard materials such as iron ore, granite, limestone, quartzite, sandstone, and pebbles.

Based on the latest technology and decades of production experience, the cone crusher developed by SBM has excellent crushing efficiency and a good hydraulic control system and is widely used in secondary crushing of various mines and rocks.

SBM cone crusher currently has 4 main series, CS cone crusher, PY cone crusher, HCS cone crusher, and HPC cone crusher. Their structure is different, so their functions are also different. If you need a cone crusher, you can contact us at any time. You only need to provide crushing raw materials, output and other requirements, our professional and technical personnel will recommend the most suitable cone crusher for you.

CS Cone crusher is quite excellent in hard material crushing and the final product has good sharpness. The innovations like a stable lubrication system and excellent sealing system evidently reduce the production cost, helping you to achieve the highest level of profitability.

It is applied to cement mills, mining, building construction, road &bridge construction, railway construction and metallurgy, and some other industries. Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone, and some others are easily crushed by cone crusher.

Processing ability: 27-1400t/h

Max feeding size: 369mm

Product Fineness: 3-100mm

Range of application:

Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganese ore, refractory material, glass, etc.

Benefit:

1. High yields and high-grade final products.

2. With grease seal and upstage sealing element imported from Japan, provide sturdy guarantee for long-playing stable operation of the machine.

3. Overload protective system can effectively ensure the safety of the crusher.

4. Easy to control discharging size by using different crushing cavities and adjusting devices.

| Model | Movable Cone Diameter mm (inch) | Chamber Style | Opening Side | Closed Side | Discharging Opening (mm) | REV (r/min) | Power (kw) | Motor Model | Capacity (t/h) | Machine Size (mm) |

| Max.Feeding (mm) | ||||||||||

| CSB75 | 900 (3′) | Medium | 83 | 102 | 9-22 | 580 | 6-75 | Y315S-6/75 | 45-91 | 2821×1880 ×2164 |

| Coarse | 159 | 175 | 13-38 | 59-163 | ||||||

| CSD75 | 914 (3′) | Fine | 13 | 41 | 3-13 | 580 | 6-75 | Y315S-6/75 | 27-90 | 2821×1880 ×2410 |

| Medium | 33 | 60 | 3-16 | 27-100 | ||||||

| Coarse | 51 | 76 | 6-19 | 65-140 | ||||||

| CSB160 | 1295 (4 1/4′) | Fine | 109 | 137 | 13-31 | 485 | 6-185 | Y355M2-6/185 | 109-181 | 2800×2342 ×2668 |

| Medium | 188 | 210 | 16-31 | 132-253 | ||||||

| Coarse | 216 | 241 | 19-51 | 172-349 | ||||||

| CSD160 | 1295 (4 1/4′) | Fine | 29 | 64 | 3-16 | 485 | 6-160 | Y355M1-6/160 | 36-163 | 2800×2342 ×2668 |

| Medium | 54 | 89 | 6-16 | 82-163 | ||||||

| Coarse | 70 | 105 | 10-25 | 109-227 | ||||||

| CSB240 | 1650 (5 1/2′) | Fine | 188 | 209 | 16-38 | 485 | 6-240 | 181-327 | 3911×2870 ×3771 | |

| Medium | 213 | 241 | 22-51 | 258-417 | ||||||

| Coarse | 241 | 268 | 25-64 | 299-635 | ||||||

| CSD240 | 1650 (5 1/2′) | Fine | 35 | 70 | 5-13 | 485 | 6-240 | 90-209 | 3917×2870 ×3771 | |

| Medium | 54 | 89 | 6-19 | 136-281 | ||||||

| Coarse | 98 | 133 | 10-25 | 190-336 | ||||||

| CSB400 | 2134 (7′) | Fine | 253 | 278 | 19-38 | 435 | 6-400 | 381-726 | 5200×4300 ×4700 | |

| Medium | 303 | 334 | 25-51 | 608-998 | ||||||

| Coarse | 334 | 369 | 31-64 | 870-1400 | ||||||

| CSD400 | 2134 (7′) | Fine | 51 | 105 | 5-16 | 435 | 6-400 | 190-408 | 5200×4300 ×4700 | |

| Medium | 95 | 133 | 10-19 | 354-508 | ||||||

| Coarse | 127 | 178 | 13-25 | 454-599 | ||||||

PY series cone crusher is applied to cement mill, mining, building construction, road &bridge construction, railway construction and metallurgy, and some other industries. Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone, and some others are easily crushed by cone crusher.

Processing ability: 5-750t/h

Max feeding size: 300mm

Product Fineness: 3-100mm

Range of application:

Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganese ore, refractory material, glass, etc.

Benefits:

1. High productivity; high quality.

2. Less machine stop time.

3. Easy maintenance and low cost.

4. Unique crushing ability in primary, secondary, and tertiary crushing.

| Model | Diameter of Bottom End of Conical Crushing Head(mm) | max feeding size | adjustment range of discharge opening | capacity(t/h) | power | Rev. of Eccentric shaft | weight (T) | Overall dimension(mm) |

|---|---|---|---|---|---|---|---|---|

| PYB600 | 600 | 75 | 12-25 | 40 | 30 | 356 | 5 | 2234 × 1370 × 1675 |

| PYZ600 | 600 | 35 | 3-13 | 5-23 | 30 | 356 | 5.3 | 2234 × 137 × 1675 |

| PYB900 | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692 × 164 × 2350 |

| PYZ900 | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 11.2 | 2692 × 164 × 2350 |

| PYD900 | 900 | 50 | 3-13 | 15-50 | 55 | 333 | 11.3 | 2692 × 164 × 2350 |

| PYB1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790 × 1878 × 2844 |

| PYZ1200 | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 25 | 2790 × 1878 × 2844 |

| PYD1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 300 | 25.3 | 2790 × 1878 × 2844 |

| PYB1750 | 1750 | 215 | 25-50 | 280-480 | 160 | 245 | 50.3 | 3910 × 2894 × 3809 |

| PYZ1750 | 1750 | 185 | 10-30 | 115-320 | 160 | 245 | 50.3 | 3910 × 2894 × 3809 |

| PYD1750 | 1750 | 85 | 5-13 | 75-230 | 160 | 245 | 50.2 | 3910 × 2894 × 3809 |

| PYB2200 | 2200 | 300 | 30-60 | 490-750 | 260-280 | 220 | 80 | 4622 × 3302 × 4470 |

| PYZ2200 | 2200 | 230 | 10-30 | 200-580 | 260-280 | 220 | 80 | 4622 × 3302 × 4470 |

| PYD2200 | 2200 | 100 | 5-15 | 120-340 | 260-280 | 220 | 81.4 | 4622 × 3302 × 4470 |

HCS series single cylinder cone crusher with hydraulic-driven system is a kind of new type high efficient crushing equipment which is developed by SBM engineers through over 20 year’s effort of design, manufacture, sale, and after-sale service in crushing industries. It is widely used in primary crushing, secondary crushing, tertiary crushing, and fine crushing.

Processing ability: 27-660t/h

Max feeding size: 275mm

Product Fineness: 10-100mm

Range of application:

Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganese ore, refractory material, glass, etc.

Benefits:

1. High production capacity and excellent grain type of output product

2. Special bearing design for much more carrying capacity and longer life

3. The enhanced body design makes it quite a reliability

4. Easy to adjust discharging opening and to maintain by using optimized hydraulic lubrication

| Model | Movable Cone Diameter (mm) | Chamber Style | Max Feeding(mm) | Discharge Opening(mm) | Capacity(t/h) | Power(kw) | Machine Size(mm) |

| HCS100 | 790 | EC | 135 | 10-32 | 46-128 | 90 | 1550×1575×1965 |

| C | 90 | 10-25 | 43-118 | ||||

| M | 65 | 8-16 | 36-76 | ||||

| MF | 50 | 6-13 | 29-68 | ||||

| F | 35 | 4-10 | 27-57 | ||||

| EF | 28 | 6 | 30-40 | ||||

| HCS160 | 956 | EC | 180 | 13-38 | 69-215 | 160 | 1875×1920×2400 |

| C | 145 | 13-32 | 65-197 | ||||

| MC | 115 | 10-25 | 60-180 | ||||

| M | 90 | 10-22 | 60-160 | ||||

| MF | 75 | 8-19 | 61-125 | ||||

| F | 50 | 6-19 | 45-105 | ||||

| EF | 35 | 6 | 70-90 | ||||

| HCS250 | 1150 | EC | 215 | 16-44 | 110-380 | 250 | 2100×2320×2780 |

| C | 175 | 13-38 | 100-385 | ||||

| MC | 140 | 13-32 | 95-325 | ||||

| M | 110 | 13-25 | 115-335 | ||||

| MF | 85 | 10-22 | 90-280 | ||||

| F | 70 | 8-19 | 90-235 | ||||

| EF | 38 | 8 | 100-125 | ||||

| HCS315 | 1408 | EC | 275 | 16-44 | 177-660 | 315 | 2380×2735×3265 |

| CX | 245 | 16-38 | 170-650 | ||||

| C | 215 | 16-38 | 170-640 | ||||

| MC | 175 | 16-32 | 160-552 | ||||

| M | 135 | 16-32 | 195-500 | ||||

| MF | 115 | 13-32 | 190-450 | ||||

| F | 85 | 13-25 | 195-400 | ||||

| EF | 65 | 13-22 | 210-300 |

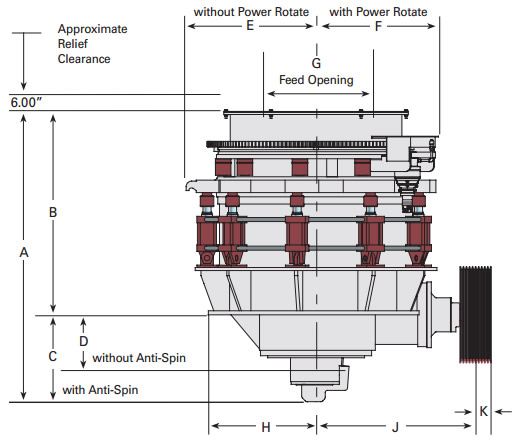

Base on the latest technology and decades of years of producing experience, SBM designed the HPC series cone crusher. It has excellent crushing efficiency and a good hydraulic control system. Now the HPC series cone crusher has wide application in secondary crushing of many kinds of mining and rock, etc.

Processing ability: 150-500 t/h

Max feeding size: 290 mm

Product Fineness: 10-30 mm

Range of application:

Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganese ore, refractory material, glass, etc.

Benefits:

1. Large reduction ratio, high production efficiency

2. Less consumption of wearing parts, low operating costs

3. Pyramid broken, perfect of product shape

4. Hydraulic protection and hydraulic pressure cavity clear a high degree of automation to reduce downtime

| Model | Movable Cone Diameter (mm) | Chamber Style | Min. Discharging (mm) | Max. Feeding (mm) | Capacity (t/h) | Power (kw) | Motor Model | Machine Size (mm) |

| HPC220 | 1220 | Coarse | 19 | 210 | 185-300 | 220 | Y2-355M1-4 | 2726×1950×2182 |

| Fine | 13 | 105 | 150-210 | |||||

| HPC400 | 1570 | Coarse | 30 | 290 | 400-500 | 400 | Y3-4002-6 | 3447×2830×2977 |

| Fine | 16 | 135 | 260-400 |

About us

SBM is an excellent manufacturer of mining ore machinery, crushers, and pulverizers in China, and a leader in ore ultrafine grinding machinery. Always adhere to “quality-oriented, customer first”. Over the years, based on our own technology and experience, we have continuously researched, developed, and improved ore crushers and ore mills. Strive to create cost-effective and high-quality machinery, improve customer experience, and bring customers higher benefits.

Our factory & showroom

Our services

Online service

No matter where you are, at home or abroad, you can always contact us. Our online consulting service team provides customers with 365 days × 24 hours of service.

Pre-sale service

SBM provides customers with free on-site exploration services, including material testing and on-site evaluation. SBM also provides complete analysis reports and project descriptions to ensure that the solution design better meets customer requirements and has higher security.

Solution

SBM provides customers with professional integrated solutions based on the results of professional on-site investigations and displays the CAD drawings and 3D drawings of each solution. With strong R&D capabilities, SBM can provide customized equipment to meet the needs of special projects.

Project management

We assign a project manager for each project to provide professional project management services, including strict project schedule management and strict internal production management, to ensure that the project is completed on schedule; to provide customers with detailed construction schedules and plans to ensure production line construction completed on time;

Install service

We provide customers with a full set of installation services such as site leveling, foundation drawing inspection, construction progress, team planning, installation guidance, and commissioning to ensure the smooth operation of the production line.

Training Services

We provide comprehensive training for the technicians of each project. We can also continue to provide support to the technical staff during the later project operation period.

The training content includes: system training, installation skills, equipment introduction, fault diagnosis and troubleshooting, equipment maintenance, equipment operation, core components, spare parts, site operations, manufacturing technology, material processing

The cone crusher can be used as a stone crusher or a sand-making machine due to the relatively large adjustment range of the discharge opening, as small as three millimeters and as large as sixty or seventy millimeters. However, in different applications, cone crushers show different characteristics.

When used as a stone crusher, the cone crusher is used for secondary crushing. It has the advantages of impact crushing and sand-making machines that do not have, such as being able to crush hard materials, small wearing parts, and more crushing cavities. But at the same time, the cone crusher also has some shortcomings, that is, there are too many needles in the finished product. In this way, when the material requirements are high, the finished product of the cone crusher cannot be used directly, and other shaping machines such as counterattacks are needed. Crusher, sand-making machine to reshape.

Compared with the sand-making machine, the wearing parts of the cone crusher are wear-resistant, which can save maintenance and replacement costs. However, there are many restrictions in use. In the choice of cavity-type, only the short-head thin type can be selected, because only the short-head thin type has a small discharge opening.

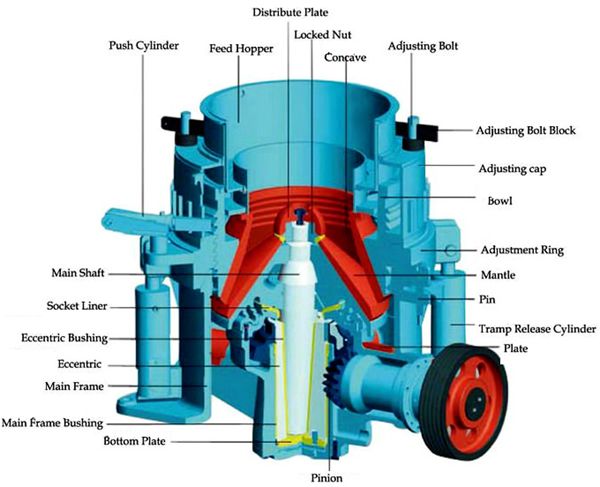

In the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device. The moving cone rotates and swings under the forced movement of the eccentric shaft sleeve. The static cone is broken by multiple squeezing and impacts. When the moving cone leaves this section, the material that has been crushed to the required particle size there falls under its own gravity and is discharged from the bottom of the cone.

NONE

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.