The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 meshes

Feed size.: <20 mm

Output: 1-20 T/H

Product features: high production and efficiency, environmental protection and energy-saving, high classification efficiency, a wide range of finished products, high degree of automation, high reliability, convenient maintenance, low operating costs, high quality, and good grain size of the finished powder

Dolomite ultrafine vertical roller mill is mainly used for the production of dolomite powder. The ultrafine vertical mill integrates crushing, drying, grinding, and conveying, and is especially suitable for large-scale production of non-metallic mineral ultra-fine powder processing. Dolomite is an important resource of calcium and magnesium, and dolomite powder can be used in many industrial fields. Such as steel metallurgy, refractory materials, glass, ceramics, building materials, chemicals, environmental protection, etc., have high market application value.

Adjustable fineness: 150-3000 meshes

Output: 1-20 t/h

Machinable materials: non-metallic ore with Mohs hardness less than 6. Such as limestone, calcium carbonate, marble, carbon black, dolomite, diatomaceous earth, and so on.

Features: The CLUM series of ultrafine vertical mills produced by SBM have outstanding features such as high grinding and selection efficiency, convenient maintenance, low operating costs, high reliability, stable product quality, excellent quality of finished products, and low overall investment costs.

Dolomite is a carbonate mineral and is the main mineral component of dolomite and dolomitic limestone. Dolomite can be used in building materials, ceramics, glass and refractory materials, chemical industry, agriculture, environmental protection, energy-saving, and other fields.

It is mainly used as a flux for alkaline refractory materials and blast furnace ironmaking; production of calcium-magnesium phosphate fertilizers and preparation of magnesium sulfate; and ingredients for the production of glass and ceramics.

Various quality dolomite products: dolomite ore, dolomite sand 6-10 mesh, dolomite powder 10-150 mesh, dolomite fine powder 150-1200 mesh, dolomite superfine powder 1200-3000 mesh.

Grinding dolomite with a dolomite ultrafine vertical roller mill, you can get 150-3000 mesh dolomite fine powder.

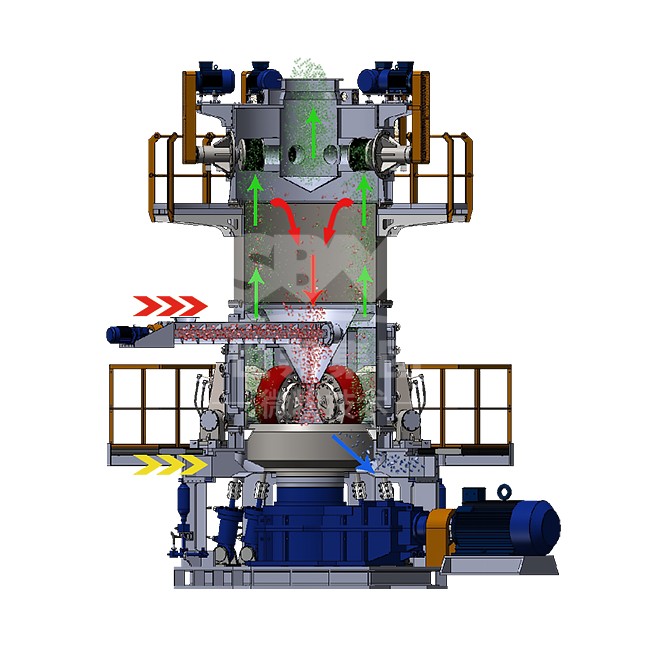

The ultrafine vertical mill is mainly composed of a motor, a reducer, a grinding roller device, a grinding disc device, a pressure device, a powder separator, a body, and an oil station.

● Special grinding roller liner

The grinding curve of roller sleeve and liner is specially designed to realize the principle of ultra-fine grinding, when used for grinding of ultra-fine powder, it is easier to form a material layer than ordinary vertical mills. Make the mill grind to the required fineness at one time.

● Using multi-head powder separator

The principle of a multi-head powder separator is adopted, and each rotor can be adjusted by frequency conversion, and the fineness of the finished product can be realized within the selected range. It does not need to go through the secondary air separation and classification, and there is no lower product.

● Material layer pre-compaction device

The pre-compaction device can ensure that the grinding part “eats” more effectively so that the material can be ground very fine. The ultrafine vertical mill has low vibration and the power is effectively used.

● Pump and suction lubrication method

The grinding roller lubrication adopts a separate lubrication station, and a single grinding roller circuit adopts double pumps and the pump and suction work at the same time. Even if the grinding roller bearings are fully lubricated and cooled, it can also ensure that there will be no excessive oil storage in the grinding roller bearing chamber, which may lead to leakage.

● Intelligent roller pressure control

Using PLC/DCS automatic control of the grinding roller pressure control method, the grinding pressure is accurately controlled, and manual operation is not required. At the same time, it is equipped with a mechanical limit device and an electronic limit device to prevent direct contact between the roller sleeve and the grinding disc liner, avoiding destructive impact and severe vibration.

The ultrafine vertical roller mill system is composed of a host, a feeder, a classifier, a blower, a pipeline device, a storage hopper, an electric control system, and a collection system.

The basic reason why CLUM series ultrafine vertical mills are widely used: they have low power consumption. It completes several unit operations in one machine and exhibits excellent operational flexibility. It can produce a variety of different high-quality ore powders. The control production process is as follows:

Crushing: The calcium carbonate stone of 400~500mm is coarsely crushed and secondarily finely crushed. Then, after iron removal, it enters the raw material warehouse for grinding.

Feeding: The crushed pellets are accurately measured from the raw material barrel by a belt scale and then sent to the central hopper between the grinding assembly and the multi-rotor high-efficiency classifier in the mill.

Raw material grinding: Three grinding rollers are used to apply force on the upper material bed of the turntable to smash the pellets into fine powder. The raw material falls from the central funnel to the center of the grinding disc, and is thrown out by centrifugal force, and is rolled into fine powder through the gap between the roller group and the grinding disc controlled by hydraulic pressure.

Raw material drying: After passing through the dam ring located at the edge of the grinding disc, the ground fine powder rises with the airflow conveyed by the deflector ring located around the grinding disc, through the activation of the fluid bed, and achieves the effect of drying and solid-gas mixing.

Pre-classification: As the fine powder rises through the airflow of the guide ring, when passing through the middle section of the mill, due to the speed change, the coarse powder will stall again and fall into the grinding disc again, and grind again with the pellets. The fine powder continues to enter the classification zone with the airflow for classification.

Final classification: Use a classifier with 3-6 rotors (a classifier installed on the upper part of the mill) to classify fine powder. In the classification zone, the powder is subjected to centrifugal force, fluid resistance, and gravity. The powder larger than the converging point will be sent back to the central hopper of the mill and be ground again with the new material. The fine powder smaller than the condensing point will follow the airflow of the fan and pass through the classification zone to become a fine powder product.

Product collection: After the fine powder passes through the airflow classifier, it is immediately taken out by the airflow from the mill and enters the pulse jet bag filter for collection. After passing through the dust collector, part of the clean high-temperature humid air will be discharged from the system into the atmosphere to maintain the normal cycle operation of the grinding system at the dew point temperature.

Product storage/transportation: The fine powder collected by the bag filter will be sent to the finished product barrel by the dense phase air transport machine (or mechanical conveying system) according to its product specifications, and the packaging machine is arranged under the finished product barrel, For bagging and shipping.

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 6 | 6 | 8 |

| Power of classifier(Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power(Kw) | 180-200 | 250-280 | 325-355 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output(t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output(t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output(t/h) | 3-4 | / | / |

Material: base on calcite

Particle size distribution: measured by microlayer diffraction particle size analyzer in British Malvern 3000 instruments

SBM Micro Powder Technology is an excellent manufacturer of ore crushing and grinding equipment in China. All equipment is directly supplied by the factory, with real prices and higher cost performance.

Our grinding mills have passed ISO9001, EU CE certification, French BV certification, Geneva SGS certification, etc., and the products comply with international standards.

The CLUM ultrafine vertical mill produced by SBM has a higher 2um content of ore powder, high powder whiteness, and a good grain shape. It is a high-end powder and has better profits.

We have a complete service system, from pre-sales to after-sales, there is professional service personnel to connect with you. We provide free installation instructions and train operators for you free of charge.

Model: CLUM

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.