The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

14/03/2025 admin

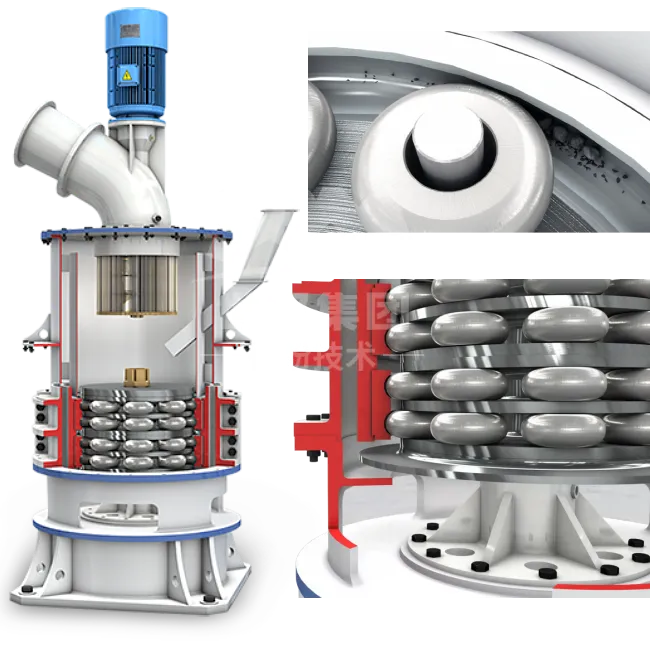

HGM series ring roller mill is a type of advanced grinding machine designed to produce fine to ultrafine powders for various industrial applications. Named after its unique configuration, the ring roller mill features grinding rollers arranged in a circular, ring-like pattern. This arrangement enables the machine to handle substantial workloads while achieving a high degree of precision.

The ring roller mill is also known by several other names that reflect its structure and grinding capabilities. Such as micro powder mill, ultrafine grinding mill, ring roller mill, three-ring grinding mill, 28 roller mill, and so on.

In this guide, we’ll explore the components, capabilities, and applications of the ring roller mill, shedding light on why it has become a staple in many industries.

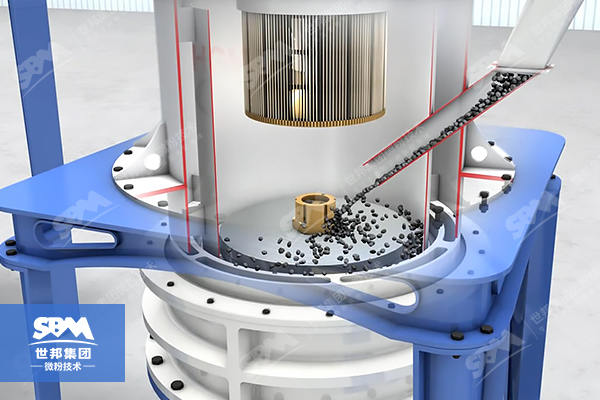

HGM ring roller mill is distinct in its structure. The core grinding area consists of a circular assembly of 18 to 44 grinding rollers, typically arranged in 3-4 layers.

These rolls grind materials against a central ring, a setup that enables consistent, efficient grinding.

This configuration not only provides stability during operation but also optimizes the grinding process, allowing for a high-quality powder output.

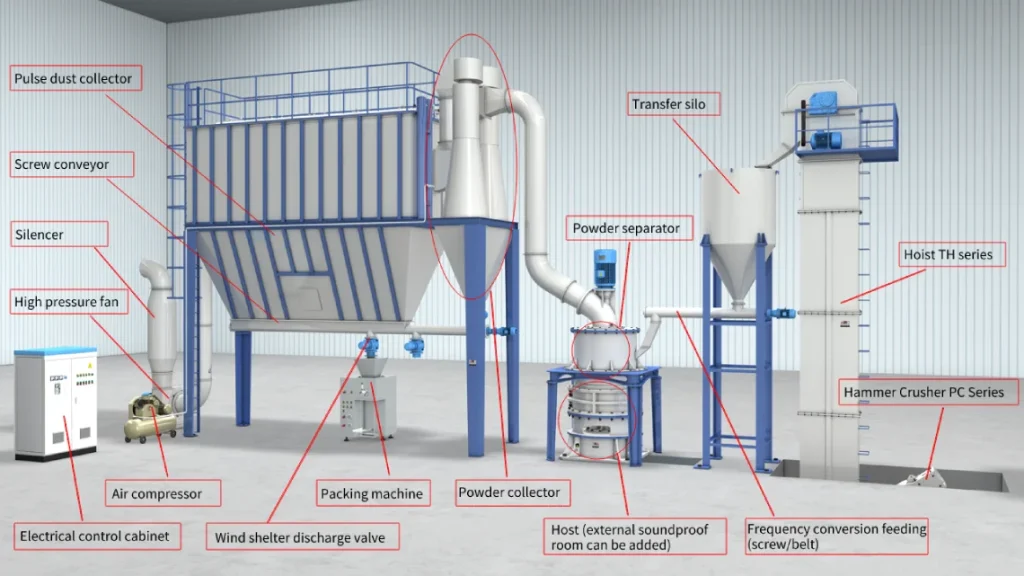

>> Several Critical Components Work Together Within HGM Ring Roller Mill System <<

1.Feeding System: This part introduces raw materials into the grinding chamber, ensuring a continuous feed for uninterrupted processing.

2.Powder Concentrator: This system separates the fine powder from coarser particles, ensuring only the desired particle sizes exit the mill.

3.Main Grinding Unit: The heart of the machine, where the grinding rolls and ring interact to pulverize the material.

4.Pulse Dust Collector: This system separates the fine powder from coarser particles, ensuring only the desired particle sizes exit the mill.

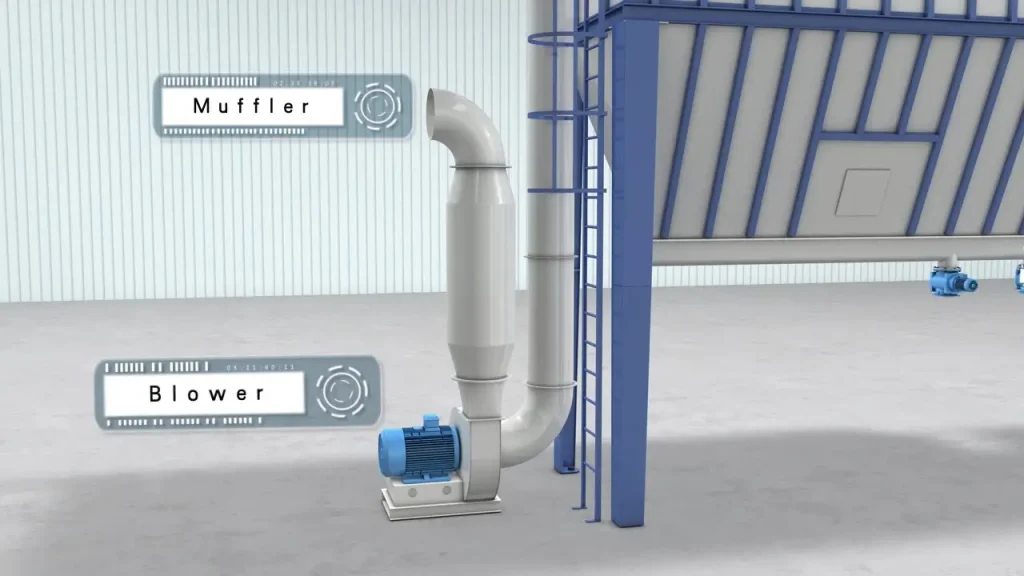

5.High-Pressure Fan: Used to generate airflow within the system, facilitating material movement and enhancing grinding efficiency.

6.Electrical Control Cabinet: This unit houses the controls for the mill’s operations, enabling precise adjustments to meet specific grinding requirements.

Together, these components create an integrated grinding system that can be controlled and adjusted to meet varying production needs.

HGM ring roller mill excels at producing fine and ultrafine powders, with particle sizes ranging from 150 mesh to 3,000 mesh (where a higher mesh count indicates finer powder).

Tips: 150 mesh equates to particles roughly 100 microns in size, while 3,000 mesh results in particles as small as a few microns.

Specifically, HGM ring roller mill can produce powders with a particle size distribution in which D97 (97% of particles) measures less than 5 microns. Additionally, as much as 60% of particles can reach sizes as fine as 2 microns, which is ideal for specialized applications requiring ultrafine consistency.

Another important capability of HGM ring roller mill is its high production output. Certain models can process up to 30 tons of material per hour, making it an excellent choice for industries with high-volume needs.

This combination of fine grinding capacity and robust throughput positions the ring roller mill as one of the most versatile and widely-used options in the powder processing industry.

One of the primary uses of the ring roller mill is in processing non-metallic minerals, especially those with a Mohs hardness rating of 7 or below. This includes materials such as:

Limestone

Dolomite

Barite

Bentonite

In particular, the mill is renowned for its efficiency in grinding ground calcium carbonate, a critical material for industries requiring high-purity and fine-powder calcium carbonate for various end products. With its high capacity and fine-tuning abilities, the ring roller mill meets the diverse needs of these industries and provides a dependable solution for consistent powder production.

The ring roller mill offers several advantages that contribute to its popularity in the fine and ultrafine powder industry:

SBM Shanghai Ultrafine Powder Tech. Co., Ltd, a prominent manufacturer, produces 5 main models of ring roller mills, each designed to match different requirements for powder fineness and production capacity. The company’s models cater to diverse needs, from small to large-scale production, and can be customized according to specific industrial requirements. This adaptability makes HGM ring roller mills a reliable choice for mineral processing companies seeking efficient, tailored grinding solutions.

Each model provides specific benefits:

HGM ring roller mill stands out as a highly efficient solution for producing fine and ultrafine powders across multiple industries. Its unique ring-and-roller structure, combined with a comprehensive set of components and customizable models, makes it a flexible and powerful tool for mineral processing enterprises. th a wide range of applications, high precision, and consistent output, it is no surprise that the HGM ring roller mill is widely regarded as one of the most effective grinding solutions in the market today.

For businesses in industries such as construction materials, plastics, paints, coatings, ceramics, and glass, the ring roller mill offers a versatile and reliable solution for achieving the desired fineness in mineral processing. HGM series ring roller mills provide a variety of options to meet different requirements, ensuring that users can find a model that meets both their production and particle size specifications.

Whether producing high-purity calcium carbonate or fine powders for coatings and plastics, the HGM ring roller mill remains a vital piece of equipment for companies around the world seeking quality and efficiency in their grinding operations.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.