The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

17/01/2025 admin

The HGM ultrafine grinding mill is an excellent choice for grinding plagioclase to ultrafine powder. This mill is known for its high efficiency, precise control over particle size, and capability to produce extremely fine powders. Below is a detailed overview of the HGM ultrafine grinding mill, including its features, benefits, and specific application for plagioclase grinding.

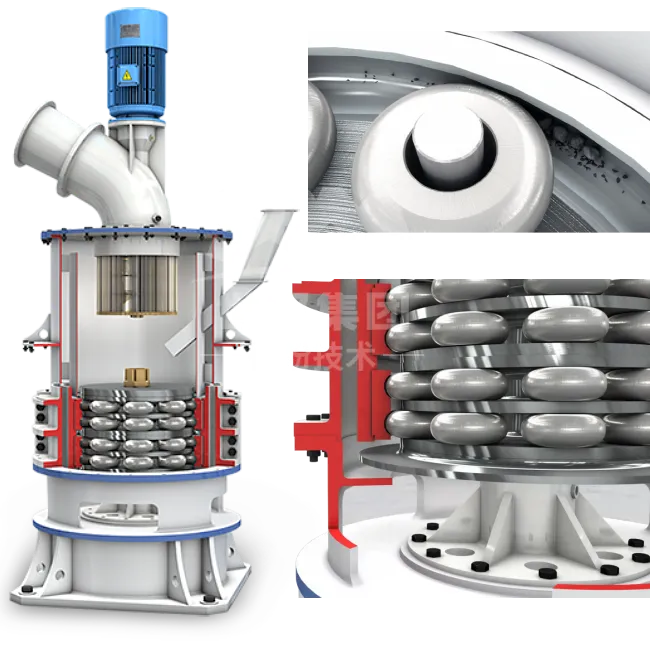

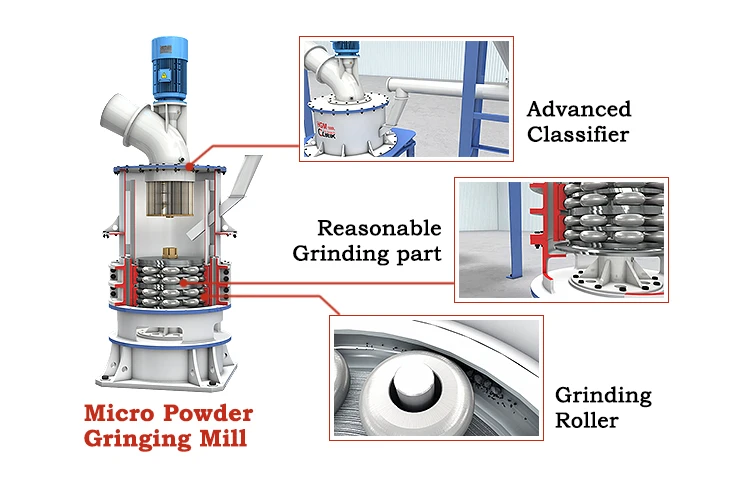

The HGM mill achieves high grinding efficiency through its multiple grinding rollers and rings, which create a high-pressure environment that facilitates fine particle breakdown.

The fineness of the output powder can be adjusted between 300-2500 mesh (47-5 microns), allowing for precise control over the particle size.

Equipped with pulse dust collectors and mufflers, the mill minimizes dust and noise pollution, making it suitable for environmentally sensitive operations.

The built-in classifier ensures that the desired particle size is achieved consistently, enhancing the quality of the final product.

Designed to consume less energy compared to traditional mills, the HGM mill operates with high efficiency, reducing operational costs.

Made with high-quality materials and advanced manufacturing techniques, the mill offers robust construction and long service life.

Capable of producing ultrafine powders with a narrow particle size distribution, essential for high-precision applications.

Suitable for grinding a wide range of materials, including plagioclase, making it a versatile choice for various industries.

The grinding process minimizes contamination, which is crucial for applications requiring high purity.

High efficiency and low energy consumption contribute to reduced operational costs over time.

Designed for easy maintenance and minimal downtime, ensuring consistent production.

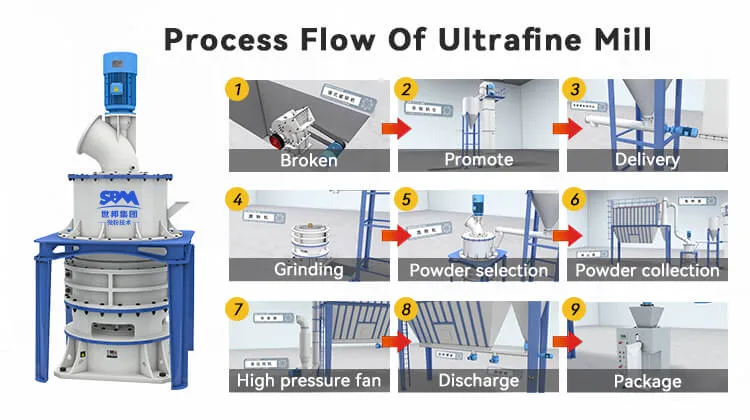

Plagioclase is fed into the HGM mill via a vibrating feeder, ensuring a continuous and controlled feed rate.

Inside the mill, plagioclase is subjected to intense grinding by rollers and rings, creating a fine powder through impact, rolling, and shearing forces.

The built-in classifier sorts the ground particles, ensuring that only particles of the desired size are collected while oversized particles are sent back for further grinding.

The final ultrafine plagioclase powder is collected through a cyclone separator or bag filter, ready for use in various applications.

Ultrafine plagioclase powder is used in the production of high-quality ceramics due to its fine particle size and consistency.

Provides a key ingredient in glass production, enhancing the material properties of the final product.

Used as a filler in paints and coatings, improving their durability and finish.

Incorporated into various construction materials for enhanced strength and performance.

Used in the production of advanced composite materials, providing specific physical and chemical properties.

The HGM ultrafine grinding mill is an effective solution for producing ultrafine plagioclase powder. Its high efficiency, precise control over particle size, and environmentally friendly operation make it ideal for industries requiring fine and consistent powder quality. By using the HGM mill, manufacturers can achieve superior product quality and reduce operational costs, making it a valuable addition to their production processes.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.