The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

09/02/2022 admin

Crusher is mainly used for crushing various ores, coal gangue, construction waste, etc. According to their different crushing performance, they are divided into various types, which are suitable for different crushing scenarios. Today, let’s talk about how to choose a mining crusher?

Mining crushers are dedicated to crushing ore materials, and are mostly used in the construction industry. Commonly used are jaw crusher, impact crusher, cone crusher, hammer crusher, impact crusher, mobile crusher, etc. We have selected three more advanced equipment that users purchase more to introduce in detail.

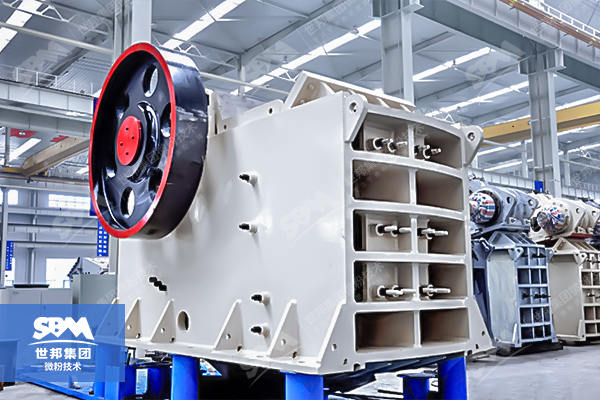

The jaw crusher belongs to the primary crusher in the crushing production line, and is specially designed to deal with the large stones that have just been mined. The feed size is up to 1500 mm, and the output size is 50-300 mm. The crushed semi-finished products are transported to the secondary crushing equipment through the conveyor to make the work more efficient.

Impact crusher is also called sand making machine. It can crush stones into machine-made sand, which is used to make concrete and other raw materials. It is the main equipment in the sand-making production line. The produced machine-made sand has uniform particle size and good particle shape. The market price is comparable to that of natural sand.

This is a piece of equipment that many customers are willing to buy now, mainly because it has high work efficiency, is convenient and fast, intelligent and environmentally friendly, and is equipped with tires or crawler drives.

When purchasing a mining crusher, in addition to the quality and price of the equipment, the model of the machine and how to match the machines to be more efficient are also our key considerations. There are many types of mining crushers, and there are differences in the size, production capacity, machine weight, and price of each specification facility. Therefore, when the user selects the model, he should select the model reasonably according to the actual production status, capital status, etc.

The strength, composition, humidity, viscosity, diameter of the material, demand for the finished product, etc., are the first things to consider when choosing a crusher. These are the direct factors that affect your choice of model. For example, the material you want to crush is pebbles with small particle size, you can directly make sand without the need for coarse crushing equipment or medium crushing equipment, which can save a lot of investment.

The investment situation is related to what type of equipment you choose, including the output size of the equipment, whether the performance is advanced or not, and the layout of the site, etc. All these need to be clarified.

The quality of the manufacturer directly determines the quality of your equipment, after-sales service, etc., and you need to focus on inspection.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.