The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

06/07/2022 admin

Gypsum is a monoclinic crystal mineral whose chemical composition is calcium carbonate, which has high sound insulation, heat insulation and fire resistance. In addition to being used in construction and industrial raw materials, gypsum can also be used in model making, paint fillers, paper fillers, medical additives, and more.

Usually there are two kinds of gypsum, one is raw gypsum and the other is anhydrite. Gypsum is usually dense or fibrous and is white, red and grey in color. Anhydrite crystals are plate-like and white or off-white in color. The two kinds of gypsum can transform each other under certain geological action.

There are many types of grinding mills available for gypsum grinding, so how to choose a suitable grinding mill?

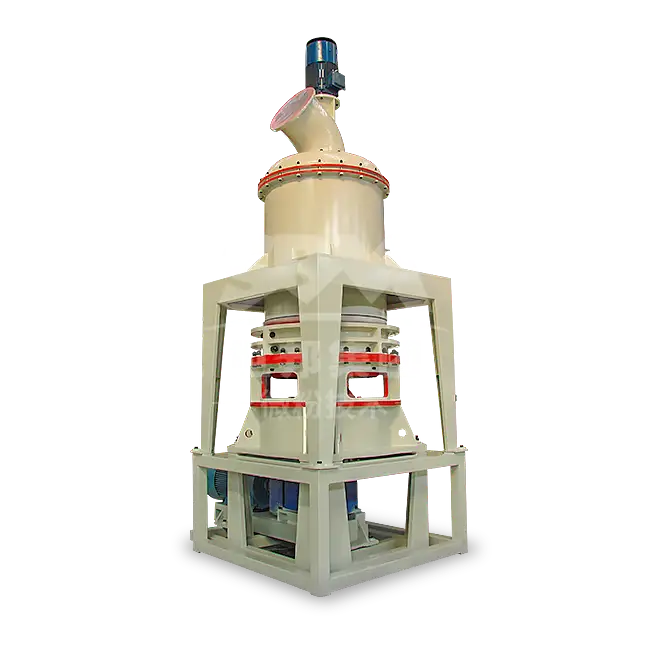

In general, the commonly used grinding mill for gypsum grinding include Raymond mill, ultra-fine grinding mill, three-ring roller mill, high-strength grinding mill and high-pressure micro-powder mill.

Raymond mill is mainly used for grinding non-metallic ores, which can grind gypsum to 325 mesh size. The grinding effect is very good and has high utilization value.

a. The Raymond mill is a vertical structure, which reduces the floor space of the equipment. From the grinding of gypsum to the formation of the particle size of the finished product, it can be an independent production system without the help of other equipment, and the performance of the complete set is very strong.

b. The screening system of the equipment makes the particle size of the obtained gypsum finished product very uniform, and the sieving rate sometimes reaches 99%, far exceeding other grinding equipment.

c. The important parts are made of good steel, and the wear-resistant parts are also made of good wear-resistant materials, which improves the wear-resistant performance of the equipment and makes the operation more safe and reliable.

d. The electrical system of the equipment adopts centralized control, so that it can basically complete the operation without human operation in the workshop, and the completion effect is very good.

The ultra-fine grinding mill is used for ultra-fine powder processing of gypsum. The particle size of the gypsum after processing is finer than other equipment, and the smallest can reach 3000 mesh, which has many performance advantages.

a. The parts of the ultra-fine grinding are fixed relatively tightly and have a compact structure, which makes the equipment run more smoothly, and also reduces a part of the floor space.

b. The operation and maintenance are very convenient, the replacement of various parts is very fast, it will not take up too much construction time, and it will not affect the construction progress of the equipment.

c. The output of gypsum is effectively increased, the grinding efficiency is very high, and the overall grinding efficiency of the equipment is improved, thereby improving the economic benefits of customers.

The three-ring powder mill is used for the processing of fine powder and ultra-fine powder of gypsum, and the grinding effect is very remarkable.

a. The replacement cycle of wearing parts is long. The reason is that the wearing parts are made of good materials, and the corresponding phenomenon of wear and tear is very small, which prolongs the replacement cycle.

c. The output of gypsum is effectively increased, the grinding efficiency is very high, and the overall grinding efficiency of the equipment is improved, thereby improving the economic benefits of customers.

c. It is equipped with special dust removal and muffler, which reduces dust and noise pollution, fully meets environmental protection standards, and truly plays a role in environmental protection.

High-strength grinding mill is a new type of grinding equipment, also known as high-strength mill. It is mainly used for high-fine grinding of gypsum. The particle size of the obtained gypsum finished product can be freely adjusted between 80-425 mesh.

a. In the process of processing gypsum with a high-strength grinding mill, it not only runs smoothly but also has very high safety. It will not pose a threat to the safety of operators and can be used with confidence.

b. The structure design is simple and the parts are very compact, making it very convenient to operate and maintain, and the parts can be replaced quickly.

c. The gypsum grinding operation is carried out continuously and the number of failures is very small, which reduces the customer’s operating cost to a certain extent.

The fineness of the gypsum finished product after high-pressure micro-powder milling can be adjusted between 500-2500 mesh, and it is mainly used for the ultra-fine powder processing of gypsum.

a. The high-pressure micro-powder mill has good quality and moderate price, which reduces the production cost of customers, and can grind the gypsum powder very well, and the particle size of the finished product is very uniform.

b. The feeding granularity is large, which can process a large amount of gypsum at one time, and the granularity of the finished gypsum product after discharging is very fine, which can fully meet the different needs of customers for the fineness of the finished gypsum product.

c. The grinding device is designed in the form of overlapping multi-stage sealing, so that it has better sealing performance and the equipment runs more smoothly.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.