The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

30/08/2022 admin

Cristobalite is also called cristobalite and white silica. It is a variant of crystalline quartz with a hardness of 6-7. It has high scattering, good matting effect, high whiteness, low density, bright color, corrosion resistance and engraving resistance. It is scratch-resistant, scrub-resistant, and high-temperature resistant. It is a good adhesive, coating, and adhesive, and has high utilization value. How to configure the cristobalite grinding powder production line equipment?

The processing of cristobalite into fine powder needs to go through two main stages of crushing and grinding. The equipment used is jaw crusher and Raymond mill, followed by feeder, elevator, powder separator, dust collector, etc. equipment, the following describes the main equipment performance characteristics.

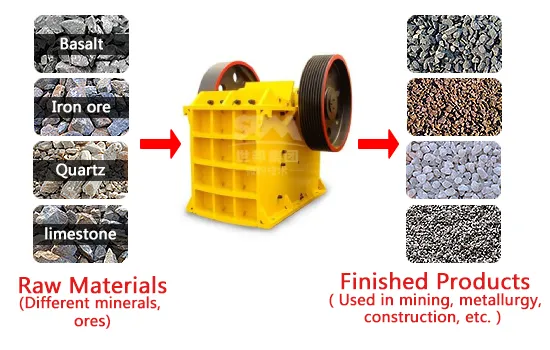

Jaw Crusher

Whether the stone is crushed, made sand or milled, it is generally necessary to use a jaw crusher for coarse crushing first, and then crush it into small stones before proceeding to the next step. The jaw crusher has strong crushing capacity, large crushing ratio, free adjustment of discharge particle size, simple structure and easy operation.

The jaw crusher is an ideal choice for the coarse crushing of cristobalite. The crushed materials can meet the production needs of users and create greater benefits for users.

The features of this equipment in operation are:

(1) The deep crushing cavity improves the processing capacity of the equipment for materials and increases the output.

(2) The flywheel can make the equipment more stable during operation and make the equipment more durable.

(3) The cristobalite particles crushed by the equipment are uniform and complete, which improves the crushing efficiency of the equipment during operation.

Advantage:

a. High output: The processing capacity of cristobalite is very large, which improves the processing capacity and crushing efficiency of the equipment, thereby greatly improving the output of cristobalite.

b. Long service life: The process and technology of the manufacturing equipment are advanced, and the raw materials of the equipment are also used well, and the service life of the equipment will be very long.

c. Low carbon and environmental protection: It is equipped with a very advanced dust removal device, so that the emission standards of its equipment fully meet the national regulations, which really plays a role in protecting the environment.

d. The particle size of the finished product is uniform: because the crushing principle of the equipment is relatively advanced, the crushed cristobalite can meet the construction requirements of all customers, and the content of the obtained finished product cube is relatively high, and the needle-shaped cristobalite is reduced.

Raymond Mill

The production capacity is 1.5-7.5t/h

The feed size is less than or equal to 35mm

The output size is 80-600 mesh

Raymond mill is an essential equipment for non-metallic ore grinding in powder industry. High production efficiency and low energy consumption. Three-dimensional structure, small footprint. Strong sealing and less pollution.

Raymond mill is the main equipment for high-fine milling of square stone, and its special advantages in the operation are as follows:

(1) The sieving rate of the material after grinding by this equipment can be as high as 99%, which increases the grinding efficiency of the equipment.

(2) The equipment can be centrally controlled, which facilitates the user’s operation and reduces the user’s investment in human resources.

(3) The vertical structure design reduces the volume and saves time and effort for users in operation.

Advantage:

a. The area of this equipment is very small, because it adopts a three-dimensional structure, which is small in size and light in weight, and can greatly reduce the investment cost of customers.

b. Due to the reasonable design of the internal structure of the equipment, there will not be any noise and vibration at the construction site, so the cristobalite grinding operation can be carried out at night.

c. The grinding fineness can be adjusted arbitrarily, and the applicability is more flexible and extensive.

d. The grinding roller and grinding ring are made of high wear-resistant materials and have a long service life.

e. The energy consumption is relatively low, saving 30,000-50,000 yuan for the cristobalite processing plant, and it can also operate 24 hours a day, and there are few failures during the work process.

Parameter of Raymond mill:

| Model | Roller | Ring | Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

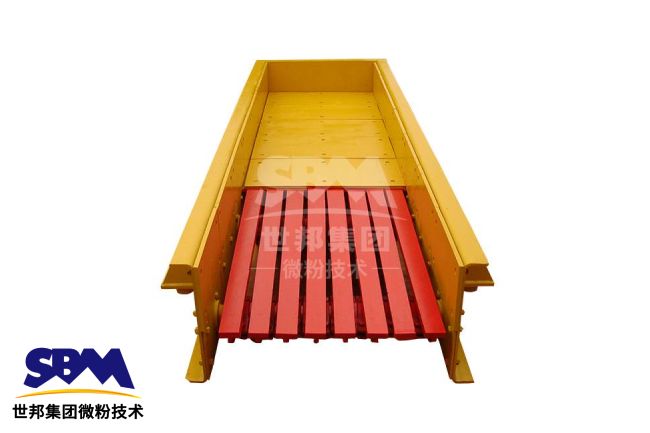

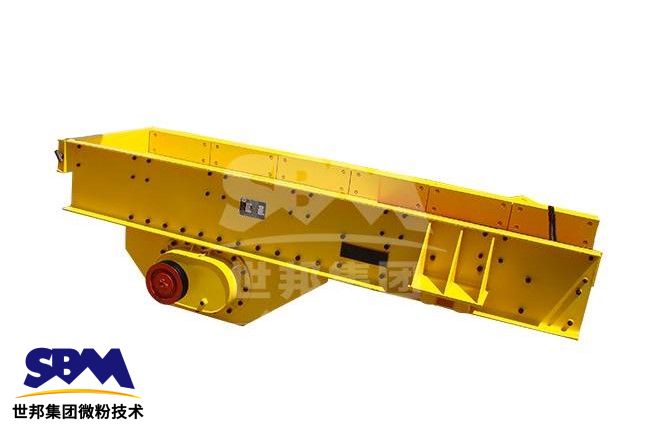

Electromagnetic vibrating feeder

The electromagnetic vibrating feeder is used to evenly supply cristobalite from the storage bin to the receiving device. The equipment has the characteristics of simple operation, small investment, high degree of automation, and small wear and tear of accessories. It is a very good feeding equipment.

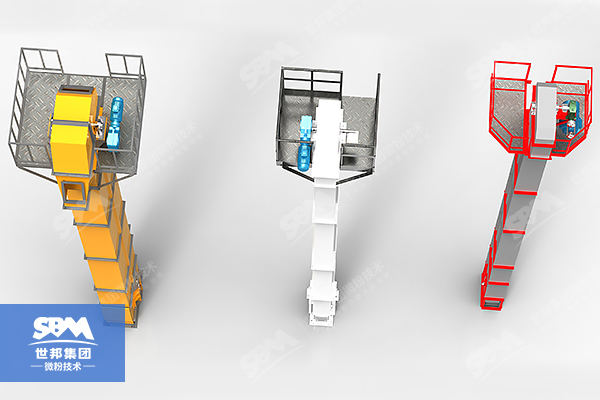

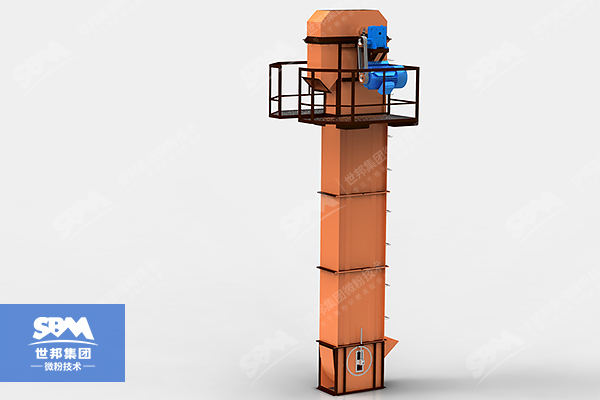

Bucket elevator

Bucket elevator is also a kind of conveying equipment, but it is a kind of equipment that conveys cristobalite vertically. The equipment has the characteristics of less wear, good performance, stable operation, long service life, wide lifting range, less environmental pollution and low noise, and plays an important role in cristobalite grinding.

During operation, the materials are firstly crushed by the jaw crusher, and then sent to the storage bin by the bucket elevator. Then, the materials are sent to the Raymond mill regularly, quantitatively and continuously through the electromagnetic vibrating feeder for grinding. The ground powder is blown to the analyzer for sorting under the action of the blower, and the sorted material is sent to the large cyclone powder collector through the pipeline. Finally, the qualified materials are discharged through the discharge port to complete the grinding operation of the materials.

1. The cristobalite production line has a good connection between the equipment, which enhances the stability of the equipment in operation and makes the cristobalite grinding production line more durable.

2. For the production line, the manufacturer is equipped with a device for dust removal and noise reduction, which reduces the harm to the environment and operators during the operation.

3. The wearing parts of the equipment are all made of high-quality and wear-resistant raw materials, which reduces the wear and tear of important parts during operation and greatly reduces the maintenance rate of the equipment.

4. The price positioning of the cristobalite grinding production line produced by SBM is very affordable, which reduces the user’s production investment in the operation and makes it more profitable.

SBM can not only provide users with more cost-effective and more reliable cristobalite grinding powder production equipment, but also a complete range of crushing, mineral processing and drying equipment. Customers can purchase according to actual needs, you can also submit project production requirements, our professional and technical personnel will configure the production line for you according to the actual situation.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.