The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

13/07/2022 admin

Sand and gravel aggregates account for 70% of the concrete volume and 80% of the mass. Doing a good job of concrete machine-made sand and gravel aggregate can not only meet the high-standard concrete production requirements, improve the quality and performance of concrete products, reduce the loss of concrete slump, and reduce the pumping pressure. The loss is small, the pumping blockage phenomenon and the maintenance time cost of the mixing and pumping equipment are reduced, and the concrete production cost can be effectively saved, and the economic profit of the commercial mixing enterprise can be improved…

Sand and gravel aggregate is loose and granular in shape and is the main component of building concrete and mortar, which can account for about 60%-75% of the volume of hardened concrete.

Depending on the source, they can be divided into:

It also called natural sand, that is, the natural sand wool excavated in the riverbed, which is formed after washing and screening.

It also known as machine-made sand, that is, the large raw stone mined, made by washing, crushing, screening and other links.

Artificial aggregates include:

(1) Thermally processed aggregates include expanded shale, expanded vermiculite, etc.

(2) Industrial by-products include slag, iron slag, powder slag, etc.

It is made of natural sand and machine-made sand in a certain proportion.

It refers to broken concrete, broken clay bricks, etc.

According to the different particle size, it can be divided into:

Rock particles with a particle size of less than 4.75mm, such as river sand, mountain sand, sea sand, etc.

Coarse aggregate refers to rock particles with a particle size larger than 4.75mm, such as pebbles and crushed stones.

According to the density of aggregate can be divided into:

Aggregate with a density between 2500-2700kg/m3

Aggregates with a density between 0 and 1000kg/m3, such as ceramsite, calcined shale, expanded vermiculite, expanded perlite, foamed plastic particles, etc.

Aggregates with a density between 3500-4000kg/m3, such as iron ore, barite, etc.

Because the quality of sand and gravel aggregates directly affects the overall performance of building concrete, the infrastructure industry usually has the following requirements for the quality of sand and gravel aggregates:

1. The surface of the aggregate is clean and contains few harmful impurities, which cannot affect the setting and hardening of the concrete and the durability of the concrete in the later stage.

2. It should have good particle grading and low porosity, which is conducive to the adjustment of admixture performance and the improvement of concrete performance.

3. Whether it is natural sand aggregate or machine-made sand aggregate, it should have good strength and firmness in order to play the role of skeleton force transmission.

4. In the process of stone mining, it should be regularly tested for alkali activity. If there is a potential danger, corresponding measures should be taken, and it should be demonstrated by professional tests.

5. The sand and gravel aggregates should have good firmness and low water absorption, and should not exceed 3.2, otherwise it will easily lead to concrete cracking.

1. The content of harmful impurities should not be higher than 1%, the content of mud lumps should not be higher than 1%, and the content of mud should not exceed 3%.

2. The sand and gravel aggregate particles are full in shape and are cubic, without too many needle-like particles, and the content of needle-like particles should not exceed 15%.

3. The ratio of aggregate compressive strength to concrete strength grade should not be less than 1.5.

4. The gradation of sand and gravel aggregates is reasonable. 1.18 or more and less than 30%, 0.15 or less should be less than 20%, 0.6 and 0.3 particles as the main body, should account for 20%-30% respectively.

It refers to the use of water washing in the process of material screening and crushing, and the washing of coarse and fine aggregates with stone washing machines and sand washing machines.

The wet processing technology is generally used when the raw material contains more mud or soft particles. When the content of finished sand and

gravel powder is high, wet production can also be used to remove part of the stone powder.

According to the different properties of the soil contained in the raw materials, the sand washing methods can be divided into screen surface washing and sand washing machine cleaning. The specific cleaning method to be used should be comprehensively analyzed and determined according to factors such as the mud content of the raw material, the nature of the soil, and the required treatment capacity.

The advantages of the wet production process are less dust pollution and high washing and screening efficiency. The disadvantage is that the water consumption is large, the cost of recycling fine sand and gravel powder and sewage treatment is high, the loss of fine sand and gravel powder is serious, and the dehydration of finished sand is difficult; when vertical impact crushing machine-made sand is used, the sand formation rate is low.

The wet production process is suitable for applications in areas with high temperature and abundant water resources but is not suitable for applications in areas with serious shortage of water resources and freezing in winter.

It means that except for spraying water in individual dust removal process links, the process of the entire production line basically does not use water.

The advantages are no water or very little water consumption, and the loss of stone powder is small. Mainly used for machine-made sand and gravel systems with clean raw materials, high sand

formation rate and low stone powder content.

The disadvantages are:

(1) Due to the high-water content of the dry-processed raw materials or the high soil content of the raw materials, the fine aggregate is not easy to sieve through, and the soil content or fine powder content exceeds the relevant standard requirements.

(2) The dust at each processing point of dry processing is relatively large, and the investment and operation cost of the dust removal system is relatively high.

(3) When the fine powder separation device is not installed, the fine powder content of the finished sand exceeds the standard.

Drought in summer and severe water shortage, and freezing in winter, it is especially suitable for dry production process.

Refers to the pre-wet and then dry production process. That is to say, the pre-screening is produced by wet method and the moisture content of the discharged material is controlled, and the shaping and sand making screening system is produced by dry method.

The advantages are relatively less water

consumption, less wastewater treatment, less stone powder loss, and less dust pollution.

The disadvantage is: after the sand making raw material is washed with water, it needs mechanical or long-term natural dehydration to ensure that the moisture content of the raw material entering the sand making machine is not more than 3%, otherwise the sand making rate and the screening efficiency of the sand making machine are low.

It is mainly suitable for the sand for hydraulic roller compacted concrete dams with low mud content in raw materials and high powder content in finished sand.

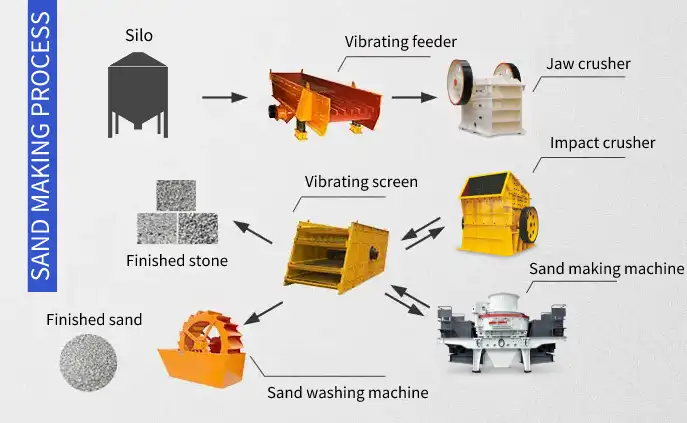

Generally speaking, there are four kinds of system composition of sand and gravel aggregate production line: feeding system, conveying system, crushing system and screening system.

The processing equipment is generally: feeder – soil removal – coarse crushing – medium and fine crushing – screening – shaping sand making – screening – fine powder separation – online monitoring.

Among them, the crushing system is the heart of the whole set of equipment, mainly including crushers, sand making machines, etc. Whether the machine-made sand and gravel processing adopts dry, wet or semi-dry methods, the main equipment for crushing, screening and sand making is almost the same.

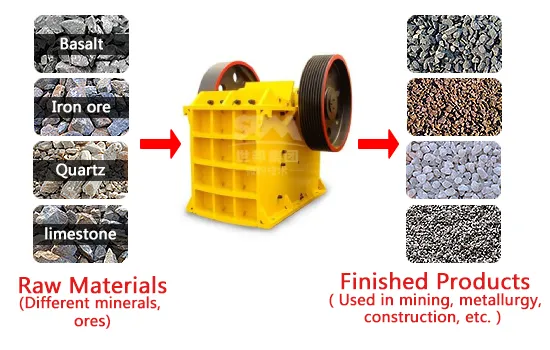

The jaw crusher is used to crush various ores and rocks with a compressive strength of 147-245MPa. The crushing ratio is large, the product size is uniform, the structure is simple, the work is reliable, the maintenance is simple, and the operating cost is low.

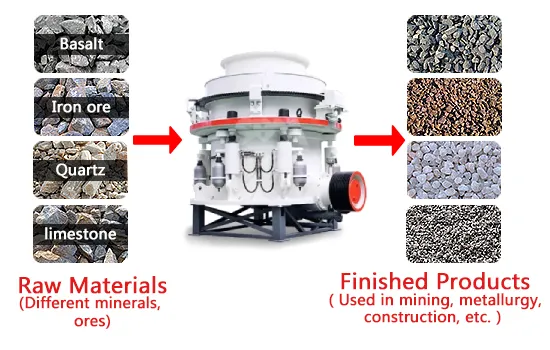

The cone crusher has large crushing ratio, high efficiency, low energy consumption, and uniform product particle size. It is suitable for medium and fine crushing of various ores and rocks. There are standard hydraulic cone crushers, single-cylinder hydraulic cone crushers and multi-cylinder hydraulic cone crushers and many other models.

The impact crusher is used for medium and fine crushing of materials below 100-500 mm, and the compressive strength can reach up to 350 MPa. It has the advantages of large crushing ratio and cubic particles after crushing. The size of the discharge particle size can be adjusted, and the crushing specifications are diversified.

The sand making machine has simple structure, convenient installation and maintenance, and low operating cost. The crushing efficiency is high, and it has the functions of fine crushing and coarse grinding. The product has excellent grain shape, cubic shape, and extremely low needle flake content. It is suitable for aggregate shaping, artificial sand making and high-grade highway aggregate production.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.