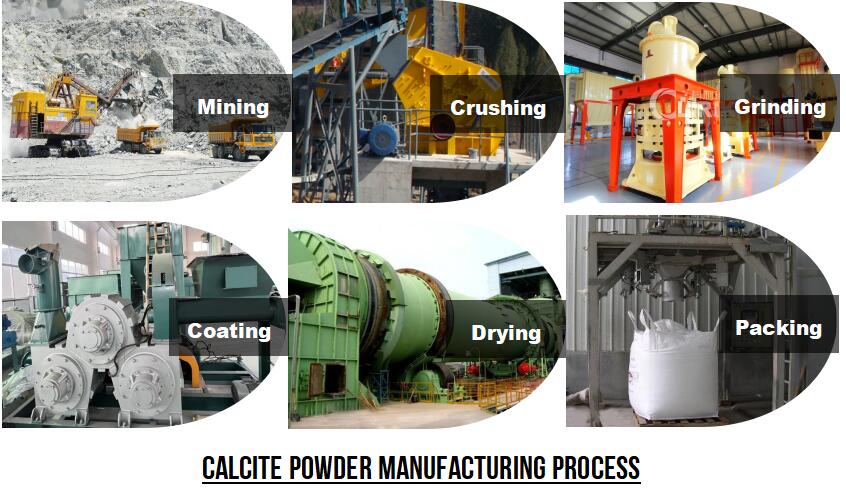

The manufacturing process of calcite powder typically involves several stages, from extraction to processing and packaging.

Jaw Crusher-Primary Crusher

Process:

- Feeding: Large chunks of calcite, as extracted from the mines, are fed into the jaw crusher.

- Action: The jaw crusher consists of two jaws, one fixed and the other moving. The moving jaw exerts a compressive force on the calcite, breaking it into smaller pieces.

- Output: The output from the jaw crusher is in the range of 6 to 10 inches (150 to 250 mm).

Impact Crusher-Secondary Crusher

Process:

- Feeding: The material from the primary crusher is conveyed to the impact crusher.

- Action: Use high-speed impact to break the material. Calcite is fed into the crusher, where it is struck by fast-moving hammers or blow bars, and then thrown against impact plates.

- Output: The material is typically reduced to sizes between 0-200 mm.

- Feed size: 350 mm

- Capacity: 50-260 t/h

Cone Crusher-Secondary Crusher

Process:

- Feeding: The material from the primary crusher is conveyed to the cone crusher.

- Action: Use compression to crush the calcite. The material is crushed between a rotating cone and a fixed outer wall.

- Output: The material is typically reduced to sizes between 3-100mm.

- Feed size: <300mm

- Capacity: 27-1400t/h

HGM Ultrafine Grinding Mill

- Feed size: <25 mm

- Output: 150~3000 meshes

- Capacity: 0.5-45 t/hT/H

- Applicable materials: non-inflammable non-explosive and brittle materials with Moh’s hardness under 6, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, fly ash, etc.

- Features: High safety and reliability. Easy to operate Energy efficient Environmental protection and pollution-free

Raymond Roller Grinding Mill

- Feed size: <35 mm

- Output: 80-600 mesh

- Capacity: 1-28 T/H

- Applicable materials: Quartz, feldspar, calcite, limestone, talc, marble, granite, dolomite, bauxite, iron ore, phosphate rock, ceramics, slag, barite, bentonite, coal gangue, coal, etc. materials.

- Features: The grinding force is large, large amount of shovels, high classification accuracy, double cyclone collector, etc.

Calcite Powder Surface Coating Machine

- CLG powder surface modification machine has a unique design of the inner cavity of the modification machine, which has both modification and depolymerization functions.

- Capacity: 40-7000 kg/h

- Applicable materials: Heavy/light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder…

- Features: Continuous operation, large capacity, both modification and dispersion functions, no pollution, simple operation

By following these steps, manufacturers can produce high-quality calcite powder suitable for various industrial applications.