The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

10/08/2022 admin

Kaolin is a clay or clay rock dominated by kaolinite minerals. Kaolin is named after the porcelain white clay produced in Gaoling Village, Jingdezhen, Jiangxi Province, China. Also known as: white cloud soil, Guanyin soil, pavilion soil powder, pottery clay.

The mineral composition of kaolin is mainly composed of kaolinite, halloysite, hydromica, illite, montmorillonite and minerals such as quartz and feldspar. The main mineral component is kaolinite, with a content of more than 90%.

The color of kaolin is white, or close to white, and the highest whiteness can reach more than 95%. The color of kaolin clay varies slightly with metal content or organic matter content. When it contains Fe2o3, it is rose red and brownish yellow; when it contains Fe2+, it is light blue and light green; when it contains Mno2, it is light brown; when it contains organic matter, it is light yellow, cyan, gray, black, etc. Kaolin is mostly cryptocrystalline dense or earthy aggregates. The hardness is 2.0~3.5, the specific gravity is 2.60~2.63, the melting point is 1780℃, the insulation is good, and the plasticity is low.

Kaolin is mainly used to make daily-use ceramics, industrial ceramics, building sanitary ceramics and refractory materials, and also as fillers or white pigments in papermaking, construction, coatings, rubber, plastics, textiles, etc. With the development of industry, agriculture and science and technology, kaolin has become a necessity for industries such as medicine and national defense.

In other industries, in recent years, with the advancement of science and technology, kaolin has been widely used in construction, textile, wire and cable, ink, food, medicine, petroleum refining and other industries.

Choose the main machine according to the output and powder fineness requirements: below 325 mesh, you can choose a Raymond mill; 150-2500 mesh can choose an ultra-fine grinding mill; 150-3000 mesh large-output production line can choose a vertical roller mill.

Adjustable fineness: 150-3000 mesh

Output: 0.2-45 t/h

Materials: Non-flammable and explosive non-metallic ores with Mohs hardness less than 7

Advantage: Small footprint, simple operation, stable operation, convenient maintenance, environmental protection and energy saving, etc.

Adjustable fineness: 50-325 mesh

Output: 1-20 t/h

Materials: Non-flammable and explosive non-metallic ores with Mohs hardness less than 9

Advantage: High efficiency, energy saving, low cost, high screening rate, etc.

Adjustable fineness: 150-3000 mesh

Output: 1-20 t/h

Materials: Non-flammable and explosive non-metallic ores with Mohs hardness less than 7

Advantage: Large output, high powder quality, environmental protection and energy saving, automatic intelligent operation, etc.

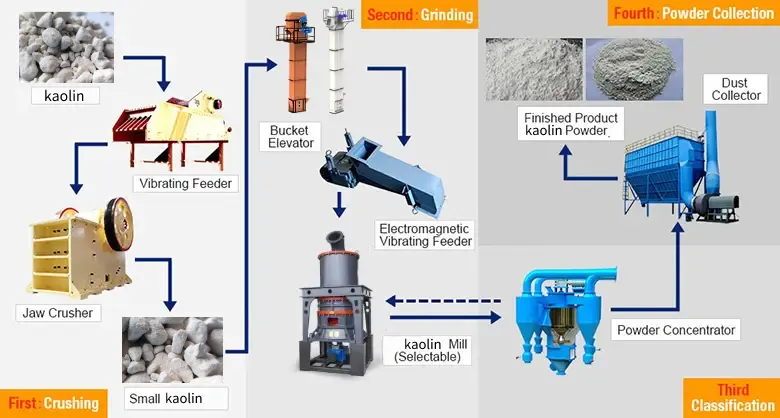

Stage 1: Crushing of raw materials

The kaolin bulk material is crushed by the crusher to the fineness (15mm-30mm) that can enter the mill.

Stage 2: Grinding

The crushed small pieces of kaolin are sent to the storage hopper through the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

Stage 3: Grading

The pulverized materials are classified by the classification system, and the unqualified powders are classified by the classifier and then returned to the main engine for re-grinding.

Stage 4: Collection of Finished Products

The powder that meets the fineness enters the dust collector through the pipeline for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is uniformly packed with a powder tanker or an automatic baler.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.