Raymond mill is a high-efficiency pulverizing mill that replaces ball mill to process ore powder.It has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance.

Discharge fineness: 80-600 mesh

Feed size: <35 mm

Output: 1-35 t/h

Materials: Raymond mill is used to process gypsum powder, talc powder, titanium dioxide powder, bone meal, shell powder, carbon black powder, coal powder, various rubber powder, alum and other chemical powders.

Product features: The Raymond mill occupies a small area, efficiently completes the milling, the finished product has uniform fineness, and the screening rate can reach 99%.

Kaolin Raymond Mill is a high-tech grinding equipment, which can make raw materials into micron or even nanometer powder and has been widely used in various industries. Such as mining, building materials, chemical industry, metallurgy and other industries, it can grind more than 300 kinds of non-flammable and explosive materials such as limestone, calcite, barite and chemical raw materials with Mohs hardness not greater than 7 and humidity below 6%. Processing, the finished product particle size can be adjusted between 80-600 mesh.

Kaolin is also called dolomite because it is white and very fine. It has good plasticity and wear resistance, and is widely used in papermaking, ceramics, wear-resistant materials, textiles, chemicals, building materials and other industries. Kaolin Raymond Mill is a kind of kaolin grinding equipment widely used in the market at present, and its grinding effect on kaolin is very significant.

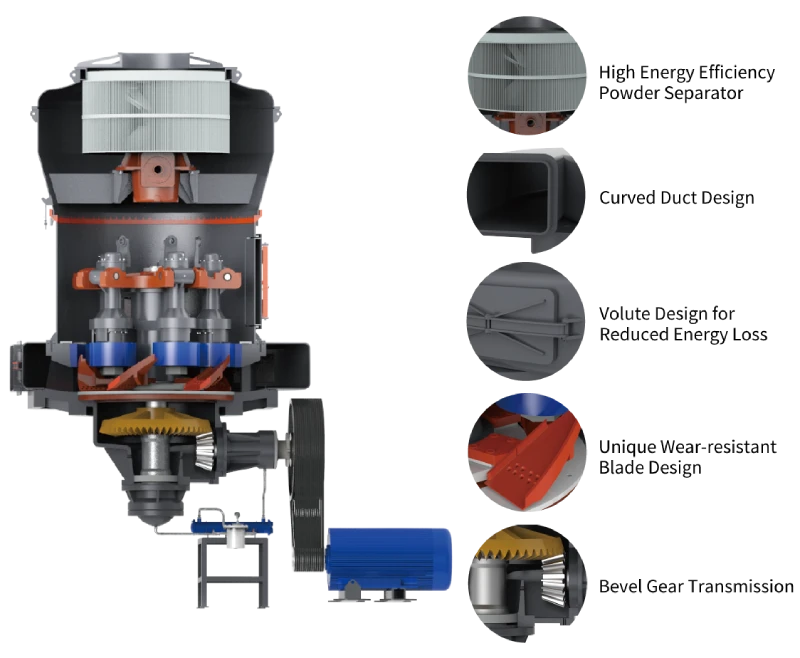

Raymond mill is a commonly used powder processing equipment, which is composed of grinding disc, grinding roller, main machine, fan, dust collector, pipeline and other parts. Specifically, the composition of Raymond mill is as follows:

1. Grinding disc: The grinding disc is the main working part of the equipment, usually made of cast iron or cast steel. A certain number of grinding rollers are installed on the grinding table for grinding materials.

2. Grinding roller: Grinding roller is a working part installed on the grinding disc, usually made of high hardness alloy steel. A certain gap is formed between the grinding disc and the grinding roller through the spring system, and the material enters between the grinding roller and the grinding disc through the gap for grinding.

3. Main engine: The main engine is the core part of the equipment, which is composed of motor, reducer, coupling, main shaft, etc., and drives the grinding disc and grinding roller to run.

4. Fan: The fan is used to suck the dust generated during the grinding process into the dust collector to ensure the environmental sanitation of the production site.

5. Dust collector: The dust collector is a device for collecting and filtering the dust generated during the grinding process.

6. Pipelines: Pipelines are used to connect various parts of equipment and transport materials and dust.

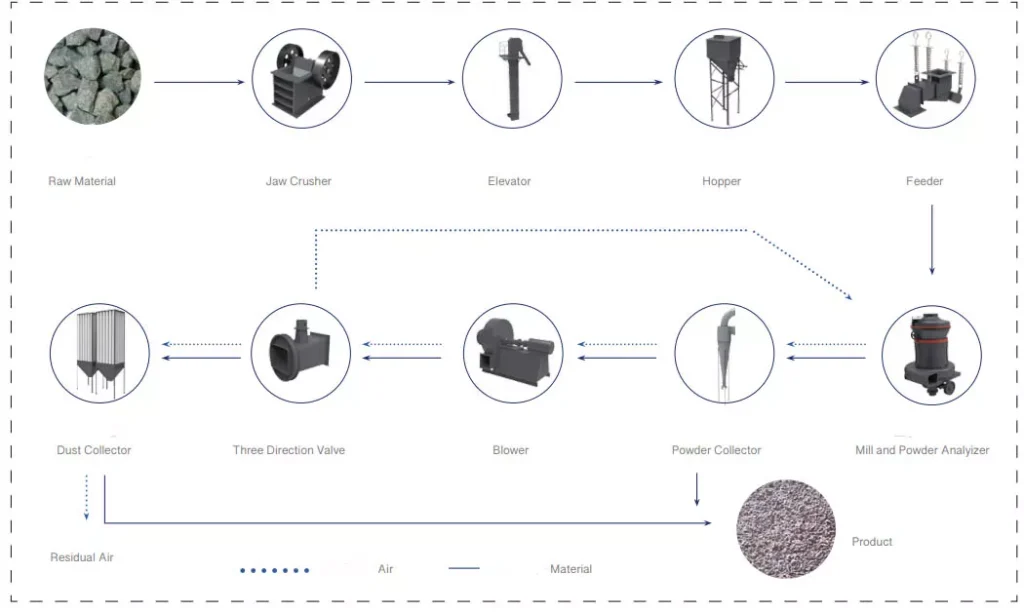

1. Crushing and grinding

The large piece of kaolin mined is crushed into small pieces of 15-40 mm in size by a crusher, and then sent to different grinding equipment through a feeder to be processed into coarse powder, fine powder, ultrafine powder, and micro powder of different fineness wait.

There are grinding rings and grinding rollers in the kaolin Raymond mill, and kaolin raw materials are crushed into powder between the grinding rings and grinding rollers. The ground kaolin powder is blown by the wind from the fan, and the qualified materials enter the cyclone separator and are collected. The unqualified material will fall back to the grinding ring under the action of gravity and continue to grind until it is blown away again, so that the grinding of kaolin is completed.

2. Impurity removal and classification

Kaolin mined from different places is mixed with different impurities, which may contain Shishi, feldspar, mica, pyrite and so on.

Kaolin is usually classified by hydraulic cyclone, spiral classifier and vibrating screen to remove coarse mineral impurities and rock impurities, and then magnetic separator is used to remove magnetic minerals in kaolin to ensure the purity of kaolin.

3. Bleaching

Kaolin has different uses, and buyers have different requirements for the whiteness and brightness of kaolin. If you want to make pigments or coatings and require high whiteness and brightness, you must use magnetic separation, chemical, flotation and other methods of bleaching. If you want to make porcelain, you have to calcined kaolin.

● Structural advantages

The kaolin Raymond mill adopts a vertical structure. The equipment is small in size, light in weight, and occupies a very small area. The internal structure design of the equipment is relatively simple, which is convenient for operation and maintenance, and shortens the downtime of the equipment. time.

● Performance advantages

a. The particle size of the kaolin finished product ground by this equipment is very uniform, which can fully meet the needs of customers, and the performance of the complete set of equipment is also very strong. From the beginning of grinding kaolin to packaging, it can be completed independently, and the completion effect is very good.

b. Not only can the kaolin grinding work be carried out for a long time, but also the equipment runs smoothly during the grinding operation, and the noise and vibration are very small, which has no impact on the lives of people around.

c. The degree of automation is very high, and the centralized control ability of the electrical system is very strong. It can basically realize that the work can be completed well without unmanned operation, reducing the intensity of manual labor.

d. Long service life. All parts are processed with high wear-resistant materials, which have strong wear-resistant and impact-resistant performance, which reduces the friction of parts and reduces maintenance costs.

| Model | Roller | Ring | Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.