The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 1-20 T/H

Product features: The equipment has the characteristics of large output, high efficiency, low energy consumption, intelligence, environmental protection, etc. It is ideal equipment for the large-scale production of ultrafine powder.

CLUM series light calcium superfine vertical mill is a new type of industrial milling equipment that integrates grinding, grading, collecting and conveying. The equipment has the characteristics of large output, high efficiency, low energy consumption, intelligence, environmental protection, etc. It is ideal equipment for the large-scale production of ultrafine powder.

CLUM superfine vertical mill is mainly used to grind non-metallic ores with Mohs hardness less than 7, especially white non-metallic ores. Because the ultrafine vertical mill adopts the principle of material layer grinding, the grinding roller wears very little, and the powder produced is high-end powder with high whiteness, low iron content, high purity and good sphericity.

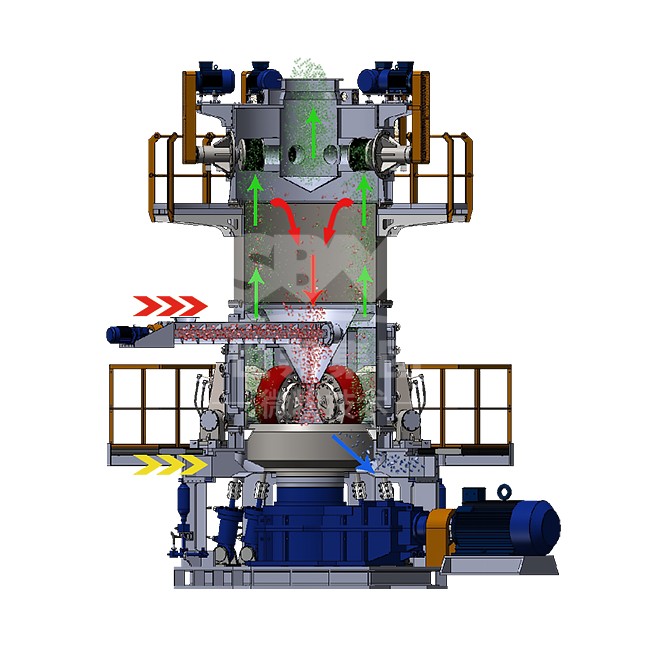

CLUM ultrafine vertical mill main machine is mainly composed of motor, reducer, machine body, grinding roller device, grinding disc device, pressure device, powder separator, lubrication station, hydraulic station and so on.

Adjustable fineness: 150-3000 mesh

Output: 1-20 t/h

Processable materials: non-metallic ores, calcite, limestone, dolomite, feldspar, barite, kaolin, calcium carbonate, marble, etc.

Light calcium is light calcium carbonate, also known as precipitated calcium carbonate. Light calcium powder can be obtained by grinding with CLUM superfine vertical mill. It is white powder, tasteless and odorless, with a specific gravity of about 2.71.

It can be used as a filler in industries such as rubber, plastics, paper, coatings and inks. Widely used in organic synthesis, metallurgy, glass and asbestos production.

It can also be used as a neutralizer for industrial wastewater, an antacid for gastric and duodenal ulcers, an antidote for acidosis, an SO2 remover in SO2-containing waste gas, a feed additive for dairy cattle, and an anti-sticking agent for linoleum.

It can also be used as a raw material for tooth powder, toothpaste and other cosmetics.

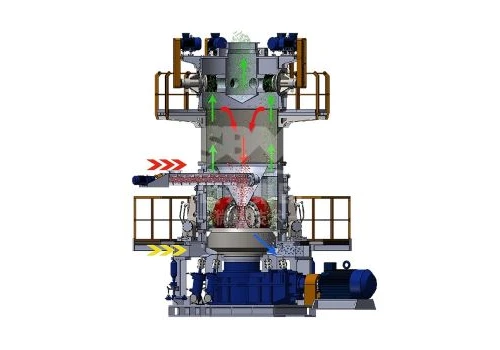

The light calcium superfine vertical mill production line is mainly composed of a milling system and a powder selection system.

The milling system mainly includes raw material primary crusher, elevator, screw conveyor, superfine vertical mill, multi-rotor powder separator, pulse dust collector, pneumatic conveying system, powder collector, packaging machine, etc.

The powder selection system mainly includes multi-rotor ultra-fine powder separator, fan, pulse dust collector, screw conveyor, etc.

The main motor drives the grinding disc in the main machine to rotate through the reducer, and the material is weighed by the belt scale and then falls into the center of the grinding disc through the hoist, screw conveyor, star-shaped feeding valve and feeding screw.

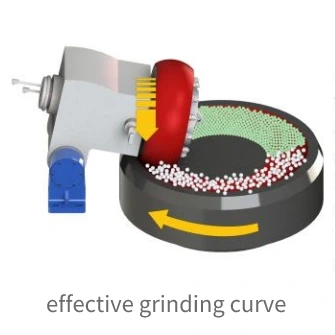

The material moves towards the edge of the grinding disc under the action of centrifugal force, and is crushed by the pressure of the grinding roll and the shearing force between the grinding disc and the grinding roll when passing through the grinding zone between the grinding roll and the grinding disc.

The pulverized material continues to move to the edge of the grinding disc until it is brought into the multi-rotor powder separator at high speed by the airflow from the high-pressure fan at the edge of the grinding disc for classification.

The powder that does not meet the requirements falls into the grinding disc for re-grinding, and the powder that meets the requirements is collected by the air flow into the dust collector, and sent to the finished product warehouse by the lifting system or the pneumatic conveying system.

The fineness of the finished product can be adjusted flexibly, the powder selection efficiency is high, the fine powder content is high, and the particle shape is good.

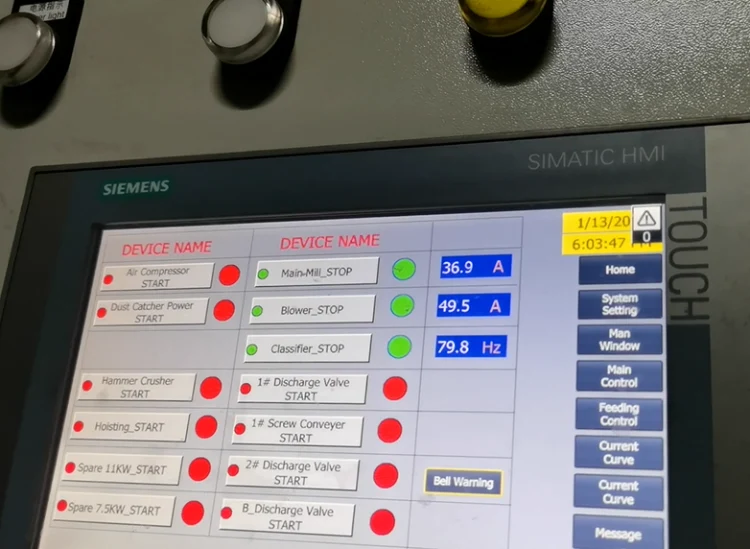

High grinding efficiency, low energy consumption, stable operation, intelligent control system and simple operation.

The grinding roller is not in contact with the grinding disc, and it is made of high wear-resistant material and has a long service life.

The whole system works under negative pressure and is equipped with a pulse dust collector, which has no dust pollution and is environmentally friendly.

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Working Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 6 | 6 | 6 |

| Power of classifier (Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power (Kw) | 180-200 | 250-280 | 325-410 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output (t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output (t/h) | 3-4 | / | / |

Material: base on calcite

Particle size distribution: measured by microlayer diffraction particle size analyzer in British Malvern 3000 instruments

Calcium carbonate ultrafine powder production line

CLUM series light calcium superfine vertical mill production line covers crushing, milling, powder selection, packaging and other parts. The production line control system is intelligent and easy to operate, which can save labor costs.

The fineness of the finished product produced by the CLUM superfine vertical mill can be adjusted flexibly, and the powder can be changed quickly. The powder has high whiteness, good shape, and the smallest can reach 3000 mesh.

Model: CLUM

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.