The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

21/12/2021 admin

Lime powder making machine can grind limestone into a fine powder(150-3000mesh). The industrial milling equipment has stable operation, simple operation, wide adjustment range, energy-saving, and environmental protection, and is favored by many customers.

In particular, the HGM series ultrafine grinding mills and CLUM series vertical roller mills independently developed and produced by SBM can be used to process limestone and other non-metallic ores. The finished powder produced has high fineness, good quality, and wide application.

Safe and reliable, long service life, intelligent control, small footprint, low investment, energy-saving, and environmental protection

Production of high-end powder, secondary powder selection, high fine powder content, high powder whiteness, good ball shape, no iron

Lime powder is a white powdery substance with calcium carbonate as the main component. The application range is very wide, the most common is calcium carbonate used in the construction industry, that is, industrial use. The other is food-grade calcium carbonate, which is widely used as a common calcium supplement.

Commonly used calcium supplement nutrient fortifiers-there are two types of calcium carbonate: one is heavy calcium carbonate, which is limestone crushed to a certain fineness by a lime mill to be used as food additives; the other is light calcium carbonate, which is Limestone is made by calcining.

● Higher output, lower energy consumption

The production capacity of the HGM ultrafine grinding mill is 40% higher than that of a jet mill and stirring mill, which is twice that of a ball mill. The energy consumption of the system is only 30% of that of the jet mill.

● 150-3000 mesh adjustable fineness

The HGM ultrafine grinding mill is equipped with a multi-head cage powder classifier, the product fineness can be adjusted between 150-3000 meshes, and the one-time screening rate can reach d97≤5μm.

● 24h sustainable work

The lubrication device of the HGM ultrafine powder mill is installed outside the main shaft, which can realize external non-stop lubrication, and can continuously produce 24 hours.

● Low noise, no dust, more environmentally friendly

HGM ultrafine powder mill is equipped with a high-efficiency pulse dust collector, muffler, and anechoic chamber. During the operation of the entire crushing system, there is low noise and no dust pollution.

Product features: higher capacity, better powder quality, better overall performance

Input size: 0-10mm

Adjustable fineness: 150-3000 mesh

Capacity: 5-18TPH

Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

.webp)

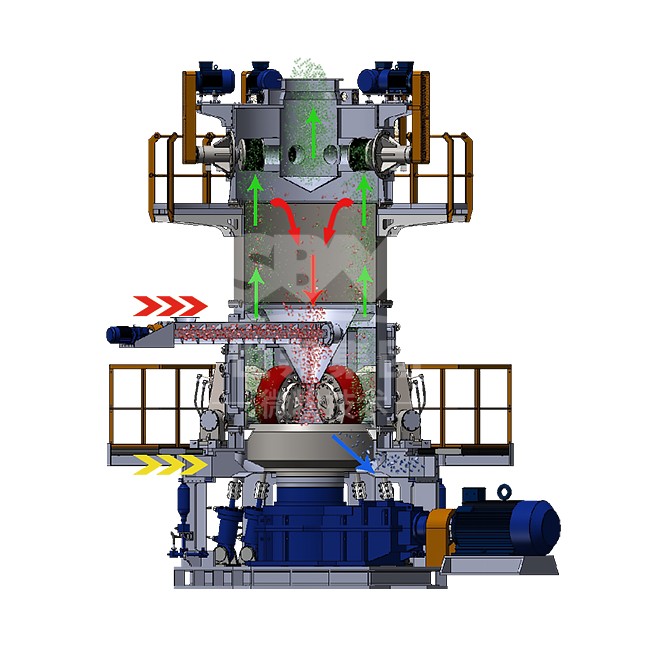

Consists of the CLUM vertical roller mill production line

Working principle of the CLUM vertical roller mill

When purchasing a lime powder making machine, we must follow the following aspects to select equipment:

★ First of all, we have to choose a large-scale manufacturer to purchase. Under normal circumstances, if the manufacturer is large in scale, the various indicators of the corresponding production equipment can meet the standard, there will be no equipment quality problems, and a lot of unnecessary troubles will be reduced during the work process.

★ Secondly, we have to choose a manufacturer with very good equipment quality and performance. To a certain extent, the quality and performance of the equipment affect the overall operation effect of the equipment. The equipment with good quality and performance has high grinding efficiency, which correspondingly increases the output of lime and the economic benefits of customers.

★ Third, price is also a factor that customers must consider when purchasing equipment. But we cannot decide which manufacturer’s equipment to buy based solely on the price. Although some manufacturers have low prices, the quality may not be guaranteed. So choose a cost-effective manufacturer.

★ Finally, we have to look at how the manufacturer’s service is. If the manufacturer’s service is good, our equipment will have a guarantee when there is a failure in the future, and it will be able to solve it as soon as possible without delaying our construction time. Therefore, under the premise of ensuring the quality and performance of the equipment, service is also a factor that must be considered.

SBM micro powder technology specializes in the production of ore milling equipment, all equipment is factory direct sales, low price, and quality guaranteed. SBM has rich production technology and management experience and provides comprehensive pre-sales, mid-sales, and after-sales services.

We provide equipment installation, commissioning, operation guidance, and other services, and be responsible for lifelong after-sales technical support. Please feel free to consult the quotation for the specific price of lime milling equipment.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.