The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

08/12/2023 admin

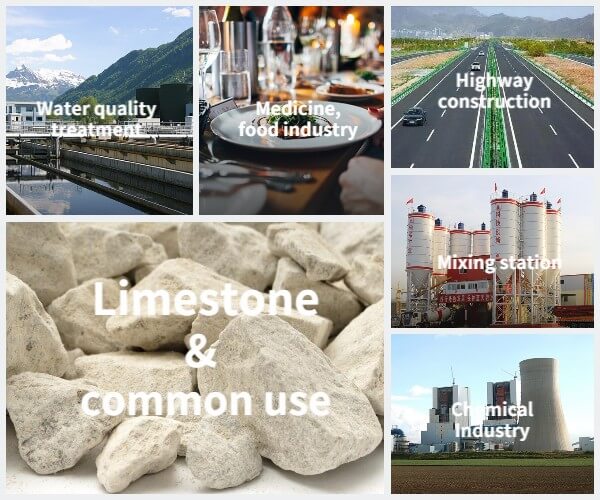

The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3. After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and chemicals. Lime is divided into quicklime and hydrated lime.

After calcining, limestone turns into calcium oxide CaO (commonly known as quicklime), which is generally in block form and is used in water treatment, asphalt improvement, desulfurization, building materials, medicine and other industries. Quicklime absorbs moisture or adds water to become hydrated lime. The main component is calcium hydroxide Ca(OH)2, which is used in environmental protection, medicine, food and other industries.

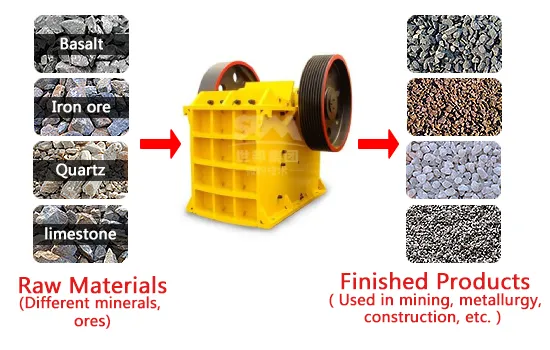

Limestone or limestone resources are abundant, and the raw ore grade can generally meet the requirements of various industrial sectors. Therefore, generally only simple mineral washing is required, and there is no need to use complex mineral processing processes for purification. The processing of limestone mainly includes crushing, grading and producing quick lime, hydrated lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc. Limestone generally adopts dry crushing process. For limestone used in metallurgy and road, the ore can be crushed and screened.

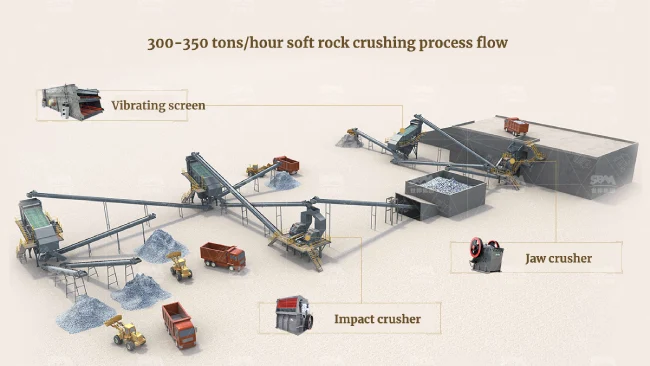

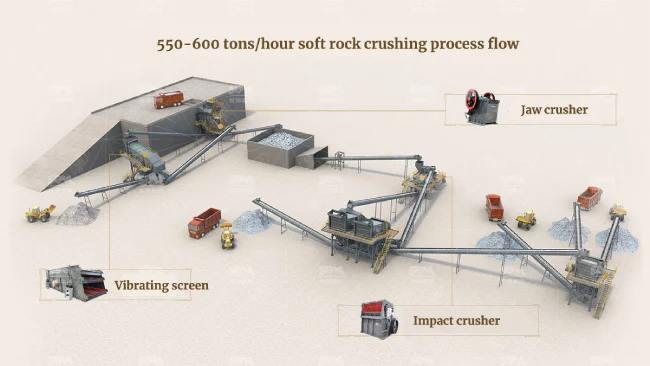

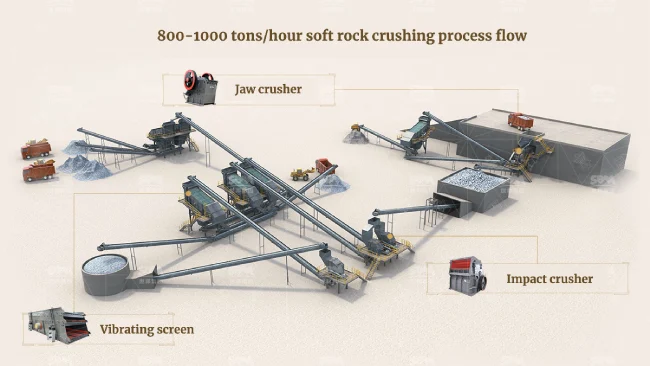

Depending on the purpose and the fineness of the output, the choice of limestone crusher will also be different. Limestone crushing can be classified according to the size of the output material, including coarse crushing, medium crushing and fine crushing.

Coarse crushing equipment: The commonly used equipment is jaw crusher. In the limestone crushing production line, the coarse crushing equipment can crush the large pieces of limestone mined into stones of 125-400mm in size.

Medium crushing equipment: Commonly used equipment are impact crushers, fine crushers, etc. After being processed by the coarse crushing equipment, the secondary crushing equipment is used for secondary crushing to break the stones into stones between 20-100mm. The particle size of the discharged stones can also be controlled by adjusting the size of the discharge port of the media crushing equipment. Get finished gravel.

Fine crushing equipment: A sand making machine is commonly used. After the limestone is coarsely crushed and medium crushed, small pieces of limestone can be crushed into 0-5mm machine-made sand under the action of the sand making machine.

More gravel line configurations and equipment: https://www.sbmmill.net/stone-crushing-production-line/

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.