The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 meshes

Feed size: <20 mm

Output: 0.5-45 T/H

Product features: Small footprint, stable operation, energy saving and environmental protection, good powder quality, flexible adjustment of fineness

The limestone ultrafine grinding mill can process 150-3000 mesh limestone powder, and the fineness can be adjusted freely. The equipment has stable operation and good performance. The produced limestone powder has good quality, high fine powder content, and a wide range of applications.

Adjustable fineness: 150-3000 meshes

Output: 0.5-45 t/h

Applicable materials: non-metallic ores, with Mohs hardness less than 6. Such as marble, calcite, dolomite, calcium carbonate, barite, pumice, etc. It can also grind coconut shells, shells, cocoa shells, bamboo, and other materials.

Features: The limestone ultrafine grinding mill is a piece of energy-saving and consumption-reducing equipment for processing limestone ultra-fine powder. Small footprint, strong complete set, wide application, simple operation, convenient maintenance, stable performance, high-cost performance, it is an economical and practical ultrafine powder processing equipment.

The main component of limestone is calcium carbonate, which is usually used as a building material and is also an important raw material for many industries. Limestone can be used to produce Portland cement and to produce coated heavy calcium carbonate products for high-end papermaking. It can be used as a filler in the production process of plastics and coatings. It can be used to produce foundry sand for machinery manufacturing. Can produce desulfurization absorbent. It can be used to produce active lime and passivated lime.

The commonly used processing technology of limestone is to use industrial mills to mechanically pulverize it into powder. Limestone can be directly crushed to obtain heavy calcium carbonate. According to the different grinding fineness, there are four different specifications in the industry: single flight, double flight, three flight, and four flight, which are used in various industrial sectors.

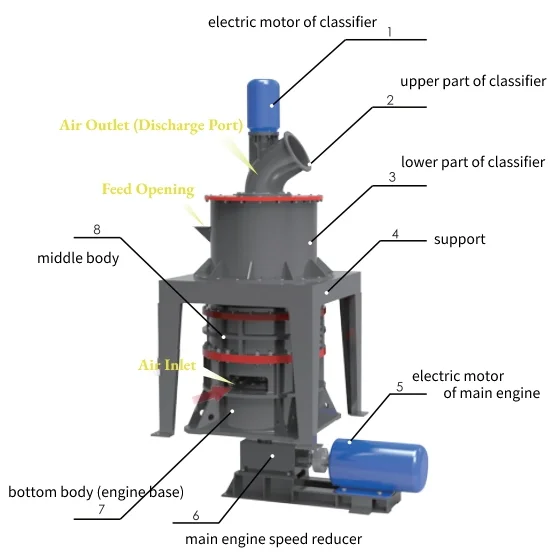

The mill production line usually includes a hammer crusher, bucket elevator, storage bin, vibrating feeder, micro-powder mill host, frequency conversion classifier, double cyclone powder collector, pulse dust removal system, high-pressure fan, air compressor, electrical control system, and other components.

Strong complete set:

The limestone grinding mill occupies a relatively small area and is highly systematic. It can form an independent production system from the rough processing of raw materials to the final material packaging.

Performance advantages:

1. High efficiency and energy saving

In the case of the same fineness of the finished product and the same motor power, the output is more than double that of jet mill, stirring mill, and ball mill.

2. High safety and reliability

There are no rolling bearings and no screws in the grinding cavity of the main machine of the limestone grinding mill, so there is no problem that the bearings and their seals are easily damaged, and there is no problem that the screws are easy to loosen and damage the machine.

3. Long service life of wearing parts

The grinding roller and grinding ring are forged with special materials, which greatly improves the utilization. Generally, it can reach more than one year, and the service life can reach 2-5 years when processing calcium carbonate and calcite.

4. Environmental protection and clean

The pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which is environmentally friendly and clean.

5. Save labor cost

The electrical system adopts centralized control, and the grinding workshop of the limestone grinding machine can basically realize unmanned operation, saving labor costs, and ensuring the safety of the staff.

Price advantage:

SBM is an excellent manufacturer of mine milling equipment in China. All grinding mills are directly supplied by the factory and there is no middleman, so the cost performance is extremely high. In addition to ultra fine grinding mills, we can provide the configuration of the entire ore milling production line. All accessories, crushers, powder modifiers, etc., are directly supplied by the factory at affordable prices.

The main part of the limestone powder grinding mill is composed of the main engine, the reducer, the analyzer, the fan, the bypass powder collector, the maintenance platform, and the electric control cabinet. The auxiliary machine part is composed of a jaw crusher, bucket elevator, electromagnetic vibrating feeder, storage bin, etc.

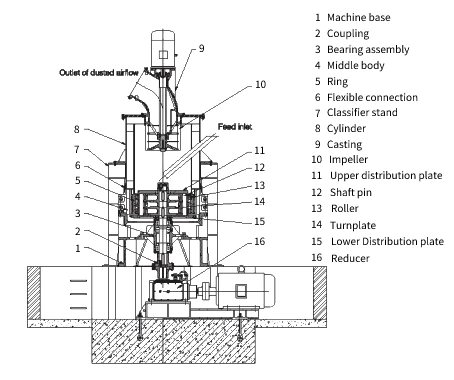

When working, the main motor drives the main shaft and the turntable to rotate through the reducer. The roller pins on the edge of the turntable drive dozens of grinding rollers to roll in the ring raceway.

The bulk material is crushed into small particles by the hammer crusher and then sent to the storage bin by elevator. Then through the vibrating feeder and the inclined feeding pipe, the materials are evenly sent to the bulk tray on the upper part of the turntable.

The material is scattered to the periphery of the circle under the action of centrifugal force. And fall into the raceway of the grinding ring, and then be impacted, rolled, and ground by the ring roller.

The material is processed into powder through the three-layer loop. The high-pressure fan sucks external air into the machine through suction and brings the crushed materials into the powder concentrator.

The rotating impeller in the classifier makes the coarse powder fall back and regrind. The fine powder that meets the requirements enters the cyclone powder collector with the airflow and is discharged by the discharge valve. The airflow with a small amount of fine dust passes through the pulse dust collector and is discharged through a fan and a muffler.

| Parameters of HGM series ultrafine mill | |||||||

|---|---|---|---|---|---|---|---|

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

● SBM integrates R&D, production, distribution, and service, and attaches great importance to communication with customers. We have established a systematic and standardized service guarantee system to ensure that each service item is handled in a timely and proper manner.

● Help customers to select equipment.

● Free arrangement of engineers to the site for actual survey and plan design.

● Strict implementation of quality standards, quality assurance of ex-factory products.

● Free logistics and transportation information, more choices for logistics and transportation.

● Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery.

● Free arrangements for engineers to guide the basic production of equipment.

● Provide free technical guidance for equipment installation and commissioning.

● The free on-site one-to-one operation, repair, maintenance, and other training.

● Professional after-sales service team, 24 hours response to customer needs.

Check the bearing temperature frequently. If the temperature is too high, check whether the lubrication and transmission parts are normal and whether the rolling distance is too tight. Find out the cause in time, take corresponding measures, and stop the machine for inspection when the situation is serious.

Check the tightness of the transmission belt frequently. Losing the belt will reduce the transmission efficiency and affect the grinding effect. Too tight will easily cause the bearing to heat up, increase power consumption and reduce the service life of the transmission belt.

Various transmission parts must be fastened and reliable, special tools should be used for disassembly or installation, and direct hitting with tools such as hand hammers is prohibited.

Always check the pneumatic components in the air circuit, air circuit, and connections for air leakage or damage. At the same time, check whether the air supply pressure meets the requirements. The use of the timing belt should also be checked frequently. If it is found to be too tight, too loose, jumping, running off, or seriously worn, it should be adjusted, repaired, or replaced in time.

Model: HGM

Payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.