The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 1-20 T/H

Product features: High output, low energy consumption, high intelligent control system, wide adjustable range of fineness, high whiteness and good sphericity of the finished product

Limestone ultrafine vertical mill is the introduction of Taiwan and Germany super fine vertical grinding technology combined with Clirik’s own years of grinding machine production experience self-developed out of a new type of industrial milling equipment that integrates grinding, grading, collecting and conveying.

Limestone ultrafine vertical mill uses multi-head Powder selection and classification structure, and the fineness of finished products can be realized in D90-5-45 microns. It can also adjust the powder selection mode according to different customer needs and can achieve the production of products with 2-micron content of 20%-70%.

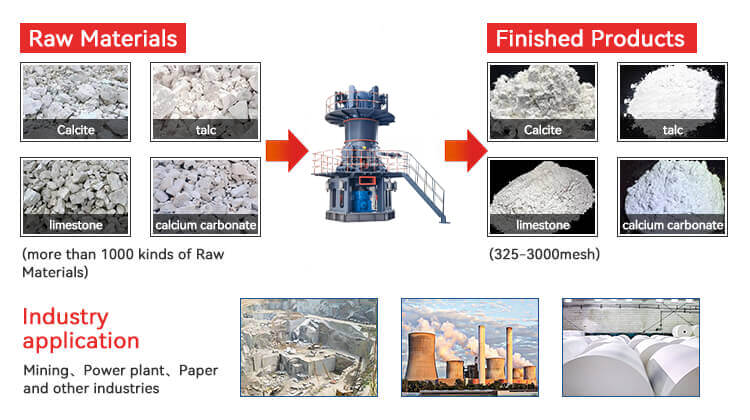

Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non- flammable and non-explosive materials under 6 (the Moh’s hardness), such as gypsum, calcium carbonate, limestone, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Limestone ultrafine vertical mill can be widely applied in the industries of chemicals, metallurgy, non-metallic ores etc. In particular, it is outstanding in processing white superfine non-metallic ore powders, providing superior quality fillers and additives for paper making, coating materials, plastics, rubber, PVC, printing ink etc.

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Working Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 6 | 6 | 6 |

| Power of classifier (Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power (Kw) | 180-200 | 250-280 | 325-410 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output (t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output (t/h) | 3-4 | / | / |

● Excellent quality of finished products

The limestone ultrafine vertical mill principle of vertical abrasive layer is adopted, the residence time of material in grinding is short, and the repeated grinding is reduced. Therefore, the iron content in the product is very little, and the whiteness and purity of the product are high. The powder content of finished products with particle size less than 2μm can reach 70%, achieving 325 mesh low residue, and can increase the secondary powder selection to select a finer particle size of finished products.

● High grinding efficiency

The main engine speed is controlled by frequency conversion, which is widely used in many kinds of materials. The specially designed grinding curve of roller sleeve and lining plate is easier to form material layer than ordinary vertical mill and can be ground to the required product fineness at one time. The use of mechanical and electronic double limit protection device, effectively prevents the roller sleeve and abrasive plate liner direct contact, avoiding destructive impact and violent vibration.

● High level of environmental protection

Low vibration, low noise. The equipment is sealed and works under negative pressure, no dust spilt, and the environment is clean. The environmental protection requirement is higher than the national standard.

● Good economic benefits

Multi-head powder separator principle, and each rotor adopts frequency conversion speed regulation, grinding fineness can be achieved in the selected range, cannot be separated twice, there is no inferior material.

● Limestone powder vertical powder grinding mill compared with other mills, when producing products of the same fineness level, the energy saving is 30% ~ 50% and the economic benefit is ideal.

● Low-cost input

Equipped with an automatic control system, it can realize remote control, easy to operate. Adopt PLC/DCS automatic control roller pressure control mode, grinding pressure precision control, no need for manual operation. The grinding roller and the grinding plate do not contact in the work, and the grinding roller and the lining board are made of high-quality materials, less wear and long service life.

The mill roller can be turned out to the chassis for maintenance, and the replacement of roller cover and lining plate is convenient and fast, reducing the loss of shutdown. The roller lubrication adopts a separate lubrication station, and the single roller loop adopts the mode of double pump and pump suction working at the same time, which not only makes the roller bearing fully lubricated and cooled, but also avoids excessive oil leakage in the roller bearing room.

CLUM Series Limestone Ultrafine Vertical Mill production line consists of main machine, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc.

CLUM ultrafine vertical mill main machine is mainly composed of motor, reducer, body, grinding roller device, grinding disc device, pressure device, powder separator, lubrication station, hydraulic station and so on.

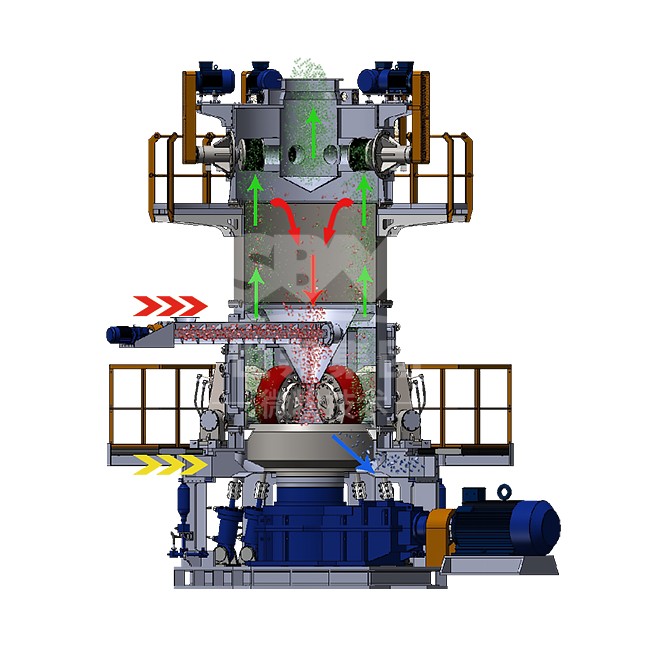

The motor drives the reducer to drive the grinding disc to rotate, and the materials to be ground are fed into the center of the rotating grinding disc by the feeding equipment. Under the action of centrifugal force, the material moves to the periphery of the grinding disc and enters the grinding roller table. Under the action of the pressure of the grinding roller, the material is crushed by extrusion, grinding and shearing.

At the same time, the wind is sprayed upwards evenly at a high speed from the air ring around the grinding disc, and the pulverized material is blown up by the high-speed airflow at the air ring, and the coarser material is blown back to the grinding disc for re-grinding.

The fine powder is brought into the classification machine by the wind for classification, and the qualified fine powder is milled along with the airflow and collected by the dust collection equipment to be the product. The unqualified coarse powder falls back to the grinding table under the action of the blades of the classifying machine and is re-ground together with the newly fed material. This cycle completes the whole grinding process.

Model: CLUM

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.