The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

11/02/2025 admin

SBM Ultrafine Powder Tech’s lithium ore grinding mills are devices used to grind lithium ore into fine powder. Different types of mills are suitable for different ores and production requirements.

Lithium ore is a mineral containing lithium and is an important raw material for the production of lithium compounds and metallic lithium. The main types of lithium ores include:

Spodumene:

The most important lithium ore, with a chemical composition of LiAl(SiO3)2. It is usually green or yellow. After high-temperature treatment, spodumene undergoes a crystal transformation, making the extraction of lithium more convenient.

Lepidolite:

A lithium-containing mica mineral with a chemical composition of K(Li,Al)3(Si,Al)4O10(F,OH)2. It is one of the main sources of lithium and is usually purple or pink.

Petalite:

The chemical composition is LiAlSi4O10. It is a lithium-containing feldspar mineral, usually white or gray.

Amblygonite:

The chemical composition is (Li,Na)AlPO4(F,OH). It is a lithium-containing phosphate mineral, usually light yellow or green.

Lithium ore is mainly used to extract lithium, which is widely used in batteries, ceramics, glass, lubricants, aerospace, medicine and other fields.

In recent years, due to the increasing demand for lithium batteries in electric vehicles and energy storage equipment, the mining and utilization of lithium ore has become more important.

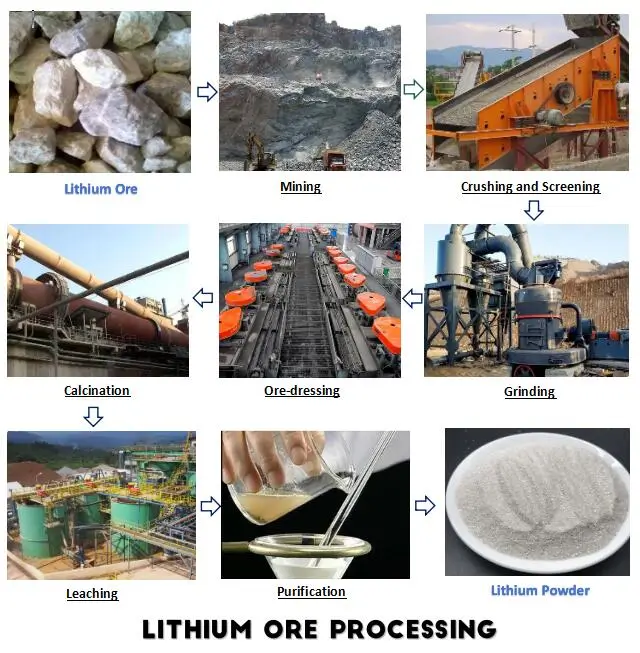

The process of processing lithium ore includes multiple steps.

There are 7 main steps from ore mining to the final extraction of lithium compounds:

1. Ore mining

2. Crushing and screening

3. Grinding

4. Ore dressing

5. Calcination

6. Leaching

7. Purification

The main equipment required in each of the above steps includes:

SBM’s lithium ore grinding mills are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill

YGM Raymond mill is a common medium-fine grinding equipment, suitable for grinding lithium ore.

Working Principle

Raymond mill grinds ore into fine powder through the rolling and grinding action of the grinding roller on the grinding ring. The ore enters through the feed port, and the grinding roller rolls on the rotating grinding ring to grind the ore into fine powder.

Features

Main Parameters

HGM Ultrafine grinding mill is specially used for ultrafine grinding, suitable for processes that require ultrafine powder for lithium ore.

Working Principle

The ultrafine grinding mill grinds the ore into ultrafine powder through the interaction of multi-stage grinding rollers and grinding rings. The ore enters through the feed port, and the multi-stage grinding rollers roll on the rotating grinding rings to grind the ore into ultrafine powder.

Features

Main Parameters

Ball mill is a commonly used grinding equipment, widely used in the fine grinding process of ore.

Working Principle

The ball mill grinds the ore into fine powder through the impact and grinding action of steel balls in the cylinder. The ore enters from one end of the cylinder, is ground by the rotating cylinder and the steel balls inside, and the fine powder is discharged from the other end.

Features

Main Parameters

CLUM vertical mill is an efficient ultrafine grinding equipment, suitable for lithium ore that requires ultrafine grinding.

Function

CLUM vertical mill is an efficient ultrafine grinding equipment, suitable for lithium ore that requires ultrafine grinding.

Working Principle

Vertical mill grinds ore into fine powder through the rolling and grinding action of the grinding roller on the grinding disc. The ore enters through the feed port, and the grinding roller rolls on the rotating grinding disc to grind the ore into fine powder.

Features

Main Parameters

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.