The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

02/06/2022 admin

Mica is a rock-forming mineral, usually in the form of pseudo-hexagonal or rhombic plate, flake, and columnar crystals. The color varies with the chemical composition and becomes darker mainly with the increase of Fe content.

The characteristics of mica are insulation, high temperature resistance, luster, stable physical and chemical properties, good heat insulation, elasticity and toughness.

The most commonly used in industry is muscovite, followed by phlogopite. It is widely used in building materials industry, fire protection industry, fire extinguishing agent, welding rod, plastic, electrical insulation, papermaking, asphalt paper, rubber, pearlescent pigments and other chemical industries.

Mica ore flotation is used to recover mica and fine-grained mica below 14 mesh in pegmatite and mica schist. In my country, the flotation of mica ore has not been applied in production. The winnowing method is suitable for areas lacking water sources and has been used in actual production.

The first stage

Ore beneficiation, flotation and winnowing of mica.

The second stage

① Mica and gangue are sorted by the difference in surface physical and chemical properties.

② Crushing → screening and classification → wind selection.

The third stage

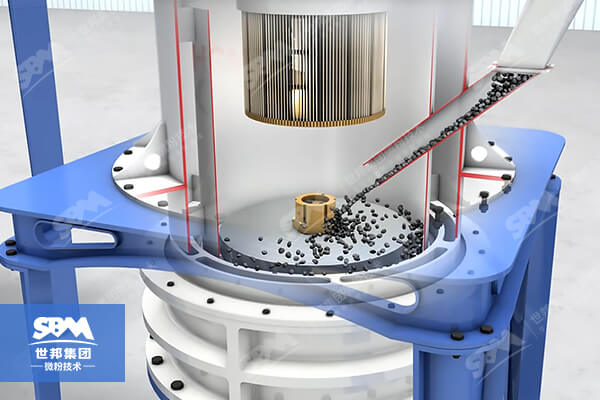

① The ore is crushed and ground to dissociate the mica monomer. Under the action of the agent, the mica becomes a foam product and separates from the gangue.

② After the ore is crushed, the mica basically forms a flake. The gangue minerals feldspar and quartz are massive particles.

The fourth stage

Break up the packaging for the finished product.

☎ WhatsApp: +86 18917951321

The most commonly used in industry is muscovite, followed by phlogopite. It is widely used in building materials industry, fire protection industry, fire extinguishing agent, welding rod, plastic, electrical insulation, papermaking, asphalt paper, rubber, pearlescent pigments and other chemical industries. In industry, flotation and air separation are used, and stone crushers and industrial grinding mills are used for crushing and grinding.

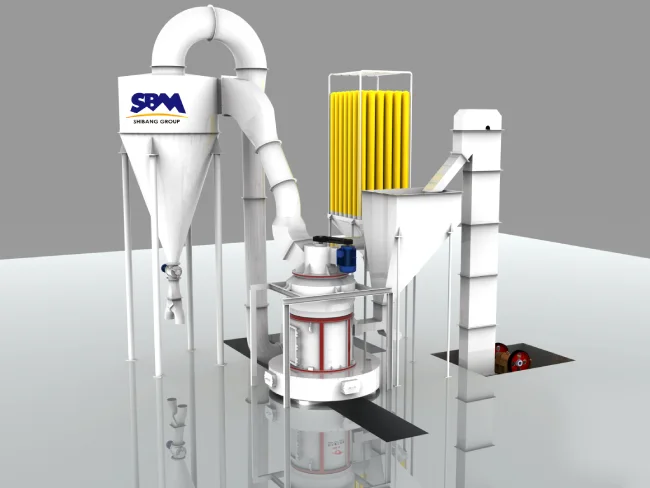

High pressure roller mill

Fineness: 80-600 mesh

Output: 1.5-7.5 t/h

High production efficiency, low system energy consumption and low operating cost.

Small footprint and long service life.

Intelligent production.

HGM Ultrafine grinding mill

Fineness: 150-3000 mesh

Output: 0.2-45 t/h

High productivity, low operating cost.

Product fineness is high, 150-3000 mesh adjustable, d97≤5μm.

High equipment stability, high level of environmental protection.

Ultrafine mica powder is used as functional filler for plastics, coatings, paints, rubber, etc., which can improve its mechanical strength, enhance toughness, adhesion, aging resistance and corrosion resistance.

In addition to its extremely high electrical insulation, acid and alkali corrosion resistance, elasticity, toughness and sliding properties, heat and sound insulation, and small thermal expansion coefficient, it is also the first to introduce smooth surface, large diameter-to-thickness ratio, regular shape, and attachment. Features such as strong focus.

In industry, its insulation and heat resistance, as well as acid resistance, alkali resistance, compression resistance and peeling resistance, are mainly used as insulating materials for electrical equipment. Secondly, it is used to manufacture steam boilers, furnace windows and mechanical parts of smelting furnaces.

Mica crushed and mica powder can be processed into mica paper and can also replace mica sheet to manufacture insulating material with low cost and uniform thickness.

Mica also has medicinal functions and can be used to treat the symptoms of chills, fever and dizziness caused by wind-induced pathogens. It can be built to remove wind and evil, enrich the five internal organs, increase fertility, make eyes bright, keep the body light and dexterous, and prolong life.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.