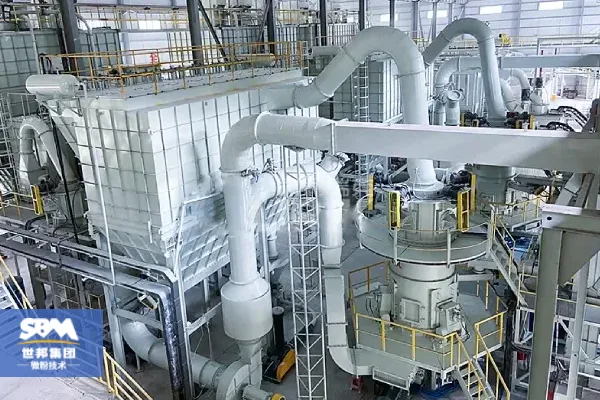

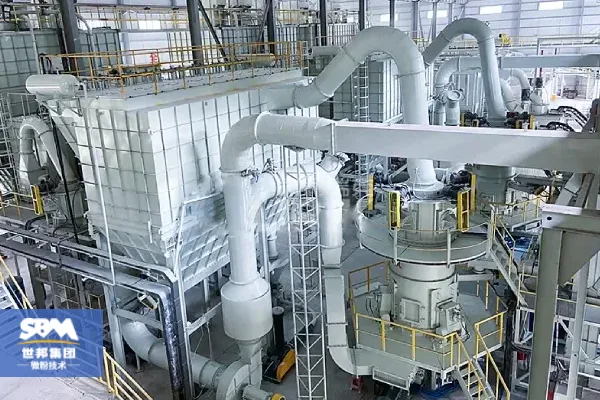

The products of Shibang Industry & Technology Group, Shanghai Ultrafine Powder Tech. Co., Ltd. are widely used in various industries of modern industry, such as metallurgy, building materials, chemical industry, mining, papermaking, ceramics, plastics, composite materials, rubber and coatings.

Regularly report real-time dynamic information of domestic and foreign mining and mineral powder industry.

The high-pressure suspension roller mill can be used to crush non-flammable and explosive materials such as barite, limestone, ceramics, slag, etc. with Mohs hardness not greater than 9.3 and humidity below 6%.

The clay ultra-fine grinding mill adopts advanced grinding technology, which is more targeted and professional. It adopts a three-dimensional structure design and occupies a smaller area. It adopts a unique electrical centralized control system, and the finished product has high purity and uniform particle size. Introduction to clay As a ceramic raw material, clay has […]

Calcium oxide is an inorganic compound, usually grayish-white, pale yellow or gray when it contains impurities, and is hygroscopic. Calcium oxide can be ground into calcium oxide powder by CLUM ultra-fine vertical roller mill. Calcium oxide powder is widely used and can be used to make calcium carbide, soda ash, bleaching powder; it can be […]

The calcite powder ground by CLUM vertical mill has a fineness of D97 up to 3000 mesh and a content of 2μm up to 70%. The powder has high whiteness, no impurities…

CLUM ultrafine vertical roller mill can grind coal gangue into pure high-quality micro powder, which is widely used in the construction industry.

Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill. Coal gangue powder is widely used in the construction field.

The HGM series ultra-fine grinding mill produced by SBM can grind perlite into fine powder of about 2500 mesh, which can be used as filler in rubber and plastic products, pigments…

The processing of cristobalite into fine powder needs to go through two main stages of crushing and grinding. The equipment used is jaw crusher and Raymond mill, followed by feeder, elevator, powder separator, dust collector, etc.

The high-pressure suspension roller mill can be used to crush non-flammable and explosive materials such as barite, limestone, ceramics, slag, etc. with Mohs hardness not greater than 9.3 and humidity below 6%.

The clay ultra-fine grinding mill adopts advanced grinding technology, which is more targeted and professional. It adopts a three-dimensional structure design and occupies a smaller area. It adopts a unique electrical centralized control system, and the finished product has high purity and uniform particle size. Introduction to clay As a ceramic raw material, clay has […]

Calcium oxide is an inorganic compound, usually grayish-white, pale yellow or gray when it contains impurities, and is hygroscopic. Calcium oxide can be ground into calcium oxide powder by CLUM ultra-fine vertical roller mill. Calcium oxide powder is widely used and can be used to make calcium carbide, soda ash, bleaching powder; it can be […]

The calcite powder ground by CLUM vertical mill has a fineness of D97 up to 3000 mesh and a content of 2μm up to 70%. The powder has high whiteness, no impurities…

CLUM ultrafine vertical roller mill can grind coal gangue into pure high-quality micro powder, which is widely used in the construction industry.

Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill. Coal gangue powder is widely used in the construction field.

The HGM series ultra-fine grinding mill produced by SBM can grind perlite into fine powder of about 2500 mesh, which can be used as filler in rubber and plastic products, pigments…

The processing of cristobalite into fine powder needs to go through two main stages of crushing and grinding. The equipment used is jaw crusher and Raymond mill, followed by feeder, elevator, powder separator, dust collector, etc.