The products of Shibang Industry & Technology Group, Shanghai Ultrafine Powder Tech. Co., Ltd. are widely used in various industries of modern industry, such as metallurgy, building materials, chemical industry, mining, papermaking, ceramics, plastics, composite materials, rubber and coatings.

Regularly report real-time dynamic information of domestic and foreign mining and mineral powder industry.

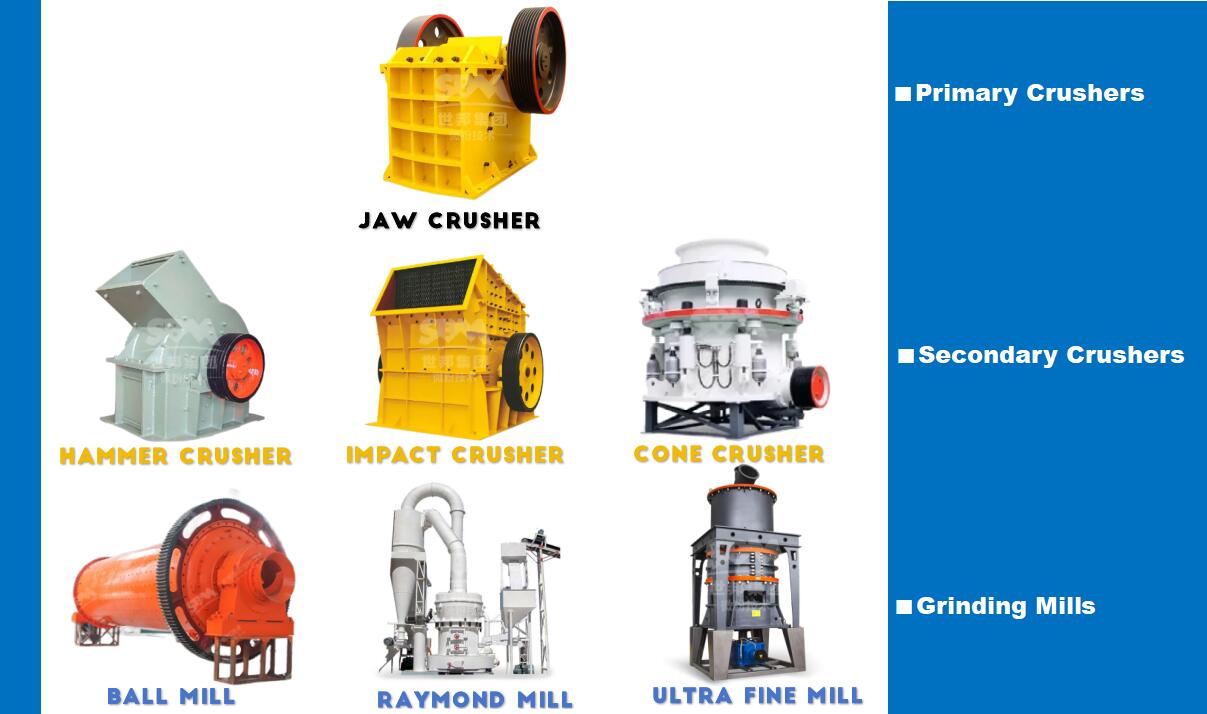

Basalt rock powder making machines include jaw crusher, cone crusher, impact crusher,Raymond mill, ultrafine mill and so on.

A 2″-3″ stone power making machine, commonly known as a stone crusher or rock crusher, is designed to reduce large stones into smaller pieces, typically for use in construction, landscaping, or other industrial applications.

CCM Powder Production Line: Raw material: custic calcined magnesia;

Equipment: HGM Series Ultrafine Grinding Mill;

Feeding size: 200-325 Mesh, D97;

Output size: 800 mesh, D90;

Capacity: 4000 kg/hour.

Lithium ore grinding mills are the devices used to grind lithium ore into fine powder. SBM’s lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill.

HGM series grinding mill for bluestone is a mining grinding mill that can make fine and ultrafine stone powder with more than 150 mesh.

The HGM125 micro powder grinding mill is an essential piece of equipment in the calcium carbonate and coal powder production line. Its ability to produce fine powders with a consistent particle size makes it invaluable in various industrial applications.

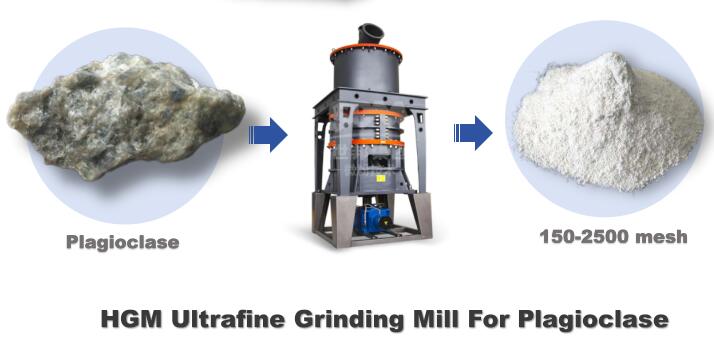

The HGM ultrafine grinding mill is an excellent choice for grinding plagioclase to ultrafine powder. This mill is known for its high efficiency, precise control over particle size, and capability to produce extremely fine powders. Below is a detailed overview of the HGM ultrafine grinding mill, including its features, benefits, and specific application for plagioclase grinding.

Choosing the right stone powder grinding mill for your needs is crucial in achieving optimal performance and efficiency in your operations. This detailed guide will help you understand the different types of grinding mills available, their features, applications, and how to select the most suitable one for your specific requirements. Stone powder grinding mills are […]

Basalt rock powder making machines include jaw crusher, cone crusher, impact crusher,Raymond mill, ultrafine mill and so on.

A 2″-3″ stone power making machine, commonly known as a stone crusher or rock crusher, is designed to reduce large stones into smaller pieces, typically for use in construction, landscaping, or other industrial applications.

CCM Powder Production Line: Raw material: custic calcined magnesia;

Equipment: HGM Series Ultrafine Grinding Mill;

Feeding size: 200-325 Mesh, D97;

Output size: 800 mesh, D90;

Capacity: 4000 kg/hour.

Lithium ore grinding mills are the devices used to grind lithium ore into fine powder. SBM’s lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill.

HGM series grinding mill for bluestone is a mining grinding mill that can make fine and ultrafine stone powder with more than 150 mesh.

The HGM125 micro powder grinding mill is an essential piece of equipment in the calcium carbonate and coal powder production line. Its ability to produce fine powders with a consistent particle size makes it invaluable in various industrial applications.

The HGM ultrafine grinding mill is an excellent choice for grinding plagioclase to ultrafine powder. This mill is known for its high efficiency, precise control over particle size, and capability to produce extremely fine powders. Below is a detailed overview of the HGM ultrafine grinding mill, including its features, benefits, and specific application for plagioclase grinding.

Choosing the right stone powder grinding mill for your needs is crucial in achieving optimal performance and efficiency in your operations. This detailed guide will help you understand the different types of grinding mills available, their features, applications, and how to select the most suitable one for your specific requirements. Stone powder grinding mills are […]