The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

10/01/2025 admin

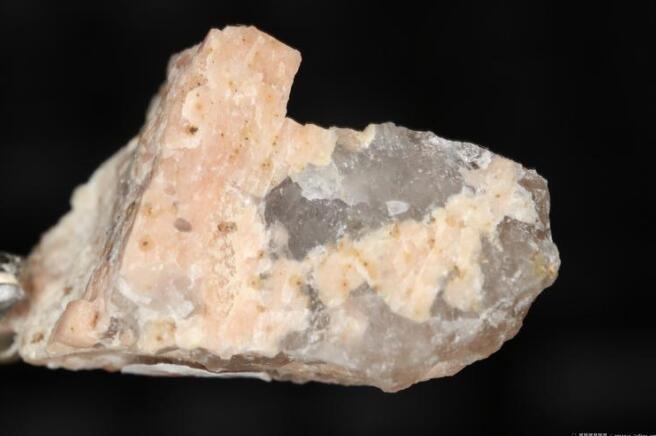

Orthoclase powder making machines are a collection of specialized equipment designed to crush, grind, and process orthoclase minerals into finely ground powders, crucial for various industrial applications such as ceramics, glass manufacturing, and construction materials.

Orthoclase is a potassium-rich feldspar mineral used mainly in the production of ceramics, glass, and construction materials, with its powdered form being essential for these industrial applications due to its chemical and physical properties.

The following orthoclase powder making machines are typically used:

These orthoclase powder making machines will be introduced in detail in the article.

Jaw crushers play a pivotal role in orthoclase powder making machines by serving as the initial crushing equipment. Their primary function is to break down large orthoclase rocks into smaller, more manageable pieces.

Operating on the principle of compressive force, jaw crushers feature a stationary jaw and a moving jaw, between which the orthoclase material is crushed.

This initial crushing process is essential for preparing the raw material for subsequent grinding and processing stages, ensuring the efficient production of finely ground orthoclase powder required for various industrial applications.

In the orthoclase powder making process, the hammer crusher serves as a crucial component for secondary crushing.

Its primary purpose is to further reduce the size of orthoclase pieces, preparing them for the subsequent fine grinding stage.

Operating on a rotating shaft, the hammer crusher features swinging hammers that forcefully crush the orthoclase material against a breaker plate.

This action effectively breaks down the orthoclase into smaller fragments, ensuring that it is adequately prepared for the fine grinding process that follows.

The HGM Ultrafine Grinding Mill stands as a cornerstone in orthoclase powder making machines, serving the crucial function of fine grinding.

Specifically designed to produce ultrafine orthoclase powder with particle sizes as small as 5 microns, this mill operates with a main unit consisting of grinding rollers and a grinding ring.

Complemented by a classifier that segregates fine particles from coarser ones, and a powder collector, typically a cyclone or bag filter, which efficiently gathers the fine powder, the HGM Ultrafine Grinding Mill ensures high efficiency and precision in producing exceptionally fine orthoclase powders.

The Raymond Mill stands as an essential intermediate grinding machine in orthoclase powder production, serving the purpose of grinding the mineral into fine powders up to 325 mesh.

Its main components include grinding rollers, a grinding ring, and a blade, working in tandem to pulverize the orthoclase material effectively.

Equipped with a classifier, the Raymond Mill ensures precise control over particle size, while a blower and cyclone collector efficiently transport and collect the fine powder for further processing. With its simple structure, ease of operation, and suitability for a wide range of materials, the Raymond Mill proves to be a versatile and indispensable tool in orthoclase powder making machines.

The Ball Mill serves as a versatile grinding machine in orthoclase powder production, offering the capability to grind the mineral into powders spanning from coarse to fine.

Its cylindrical shell houses grinding media, typically steel or ceramic balls, which rotate within, facilitating the pulverization of the orthoclase material. This grinding action, combined with the rotating shell, ensures effective comminution of the mineral particles.

One of the key advantages of the Ball Mill lies in its versatility, as it is suitable for both wet and dry grinding processes, making it adaptable to various processing requirements.

Additionally, its ability to handle a wide range of particle sizes further enhances its utility in orthoclase powder making machines.

The Vibrating Feeder plays a crucial role in orthoclase powder production by evenly supplying orthoclase to the grinding mills. Employing vibration, this machine steadily and uniformly transports the material into the processing unit, ensuring consistent and efficient feeding for optimal grinding performance.

Integral to orthoclase powder making machines, the Bucket Elevator facilitates vertical material transport by lifting crushed orthoclase to higher levels for further processing. Utilizing buckets attached to a belt or chain, this machine efficiently elevates the material, enabling seamless movement between processing stages.

In the orthoclase powder production line, the Belt Conveyor serves as a vital component for horizontal material transport, facilitating the movement of orthoclase between different machines. Powered by motors, this continuous belt system ensures smooth and efficient transfer of the material, optimizing production flow and minimizing downtime.

Critical for particle size separation in orthoclase powder production, the Vibrating Screen effectively screens and classifies orthoclase particles into different size ranges. Operating via a vibrating mechanism, this machine separates materials based on size, ensuring the desired particle size distribution for optimal product quality and performance.

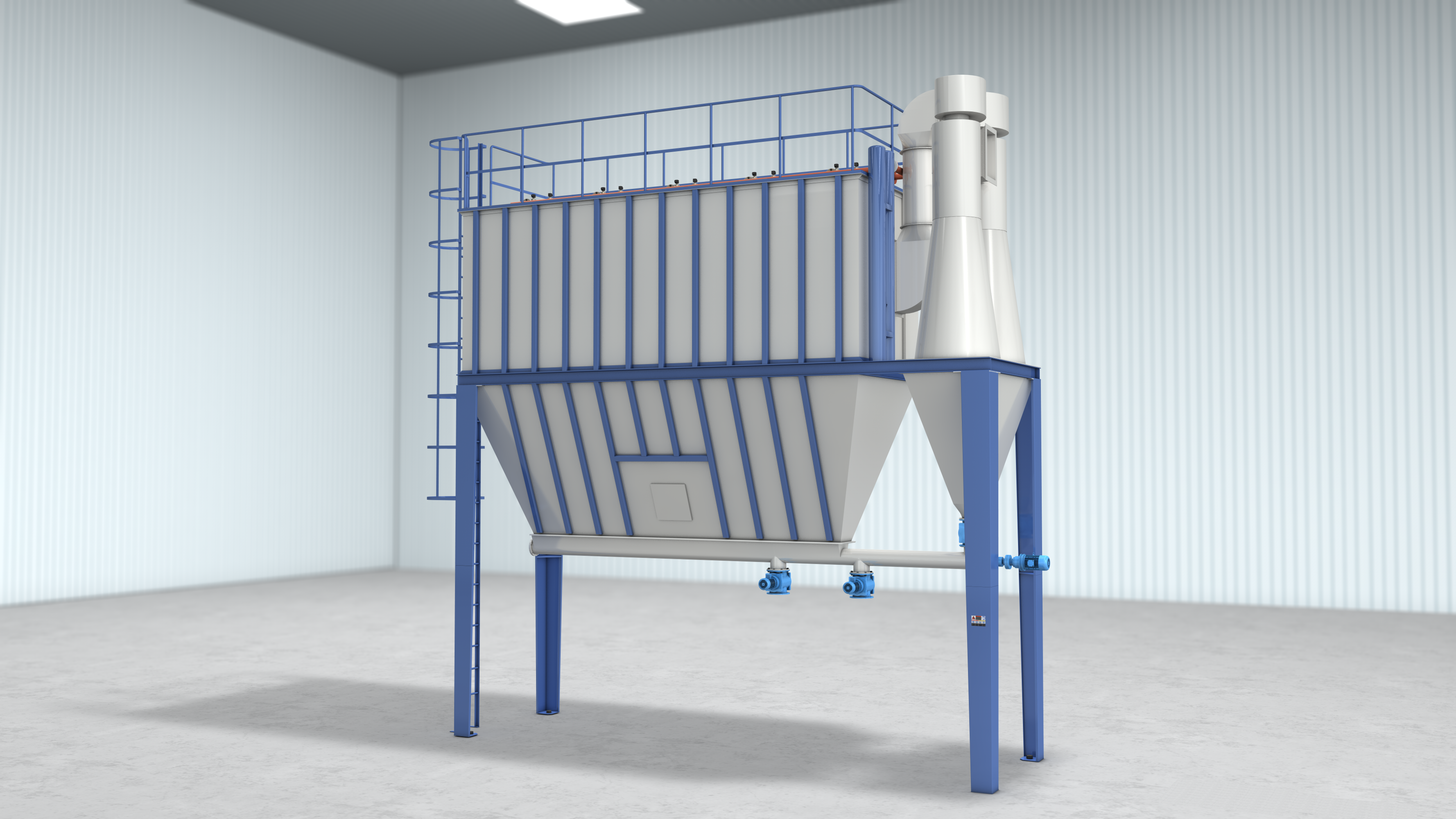

Ensuring air purification in orthoclase powder making machines, the Dust Collector plays a pivotal role in capturing dust and fine particles generated during the grinding process. Employing filters and fans, this machine removes particulates from the air, safeguarding air quality and maintaining a clean and safe working environment.

Crucial for packaging the final orthoclase powder, the Packing Machine completes the production process by accurately filling and sealing bags or containers for distribution. Automated and precise, this machine ensures efficient packaging, readying the orthoclase powder for market delivery while maintaining product integrity and consistency.

Each machine plays a crucial role in ensuring the orthoclase is processed efficiently, resulting in a high-quality fine powder suitable for various industrial applications.

Feldspar is a broad group of rock-forming minerals that includes orthoclase and plagioclase as its two main subgroups, each distinguished by their chemical composition and crystal structure:

In summary, feldspar is a group of minerals that includes both orthoclase (a potassium feldspar) and plagioclase (a sodium-calcium feldspar), each with distinct chemical compositions, crystal structures, and applications.

The above orthoclase powder making machines are also suitable for feldspar and plagioclase.

170+

Our products are exported to more than 170 countries and regions around the world

30+

More than 30 overseas branches and business organizations

30+

More than 30 overseas branches and business organizations

10

Ranked No. 1 in China’s mining machinery industry for ten consecutive years

Pre-sale

On-sale

After-sale

Free to help customers in equipment selection and scheme design.

You are always welcomed to visit SBM! Visit our prototype and showroom.

Strictly implement quality standards, and guarantee the quality of products shipped.

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery.

Overseas professional installation team provides technical guidance for equipment installation and commissioning.

Train the start-up process, teardown method, common problems and maintenance service.

Professional after-sales service team, 24 hours response to customer needs.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.