The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Output Size: 65-160mm

Feed size: 480mm

Capacity: 1-140t/h

Application: Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganeseore, refractory material, glass, etc.

The PE series jaw crusher is optimized and designed based on the traditional domestic compound pendulum crusher technology. It has a simple structure and reliable performance.

PE Jaw Crusher is mainly used in the industries of metallurgy, mining, chemical, cement, construction, refractory materials, and ceramics. It is suitable to crush hard and soft ores with compressive strength of less than 320 MPa. This machine can break materials into medium size and fine size.

The PE series jaw crushers adopt a simple structure, a deep crushing cavity an integrally welded frame, and an optimized movement style of the movable jaw, so the equipment performance has been significantly improved over the traditional jaw crushers to achieve more stable and reliable operation.

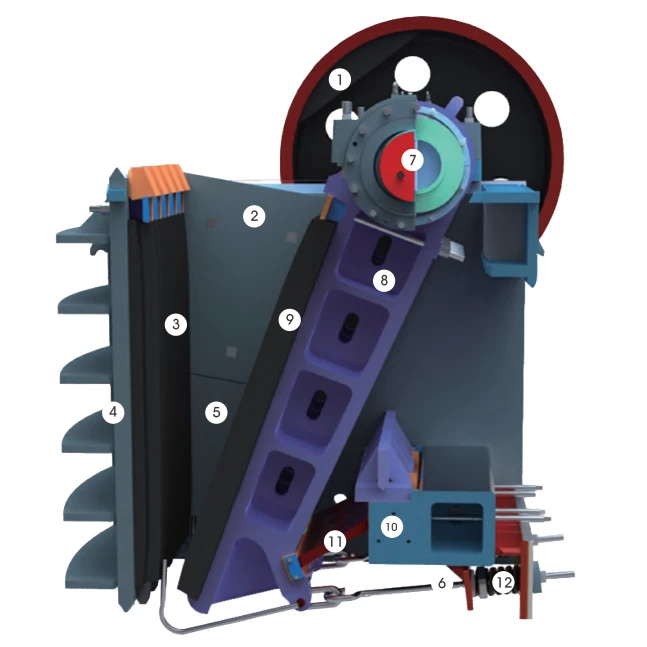

1. Flywheel

2. Upper Lining Plate

3. Fixed Jaw Plate

4. Flame

5. Lower Lining Plate

6. Tension Rod

7. Eccentric Shitt

8. Movable jaw

9. Movable Jaw Plate

10. Adjustment Device

11. Toggle plate

12. Spring

1 Low noise and less dust.

2 The crushing ratio is large, and the product size is uniform.

3 The structure is simple, the work is reliable, and the operating cost is low.

4 The lubrication system is safe and reliable, the replacement of parts is convenient, and the equipment maintenance is simple.

5 The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output.

6 Equipment energy saving: single machine energy saving is 15%-30%, system energy saving is more than doubled.

7 The adjustment range of the discharge opening is large, which can meet the requirements of different users.

Jaw crusher mainly consists of frame, eccentric shaft, jaw plate, connecting bar, adjustment part, and spring.

The movable jaw goes upward and downward through the eccentric shaft when the belt and belt wheel are driven by the motor. The angle between the movable jaw and bracket turns big when the movable jaw goes upward, which pushes the movable jaw plate to come closer to the fixed jaw plate. At the same time, materials are crushed with the movement of the movable jaw.

When the movable jaw goes downward, the angle between the movable jaw and bracket turns small. Under the force of spring and connecting bars, the movable jaw plate leaves a fixed jaw plate, and the crushed materials with qualified size are discharged from the crushing cavity. With the continuous rotation of the motor, the movable jaw crushes and discharges materials, which in turn, realizes the goal of mass production.

| Type | FeedOpening Szie(mm) | Feeding Size (mm) | Output Open Range (mm) | Capacity (t/h) | Powder (kw) | Dimension L * W * H (mm) |

| PE150 × 250 | 150×250 | 125 | 10-40 | 1-5 | 5.5–7.5 | 922 × 745 × 933 |

| PE200 × 350 | 200×350 | 125 | 15-40 | 5-16 | 7.5–11 | 1056*1142*1220 |

| PE250 × 400 | 250×400 | 210 | 20-60 | 5-20 | 15–18.5 | 1430*1310*1340 |

| PE400 × 600 | 400×600 | 350 | 40-100 | 15-60 | 30-37 | 1700*1732*1653 |

| PE500 × 750 | 500×750 | 425 | 50-100 | 40-100 | 45-55 | 2035*1921*2000 |

| PE600 × 900 | 600×900 | 480 | 65-160 | 60-140 | 55-75 | 2290*2206*2370 |

| PE750 × 1060 | 750×1060 | 630 | 80-140 | 130-260 | 90 | 2620*2302*3110 |

| PE900 × 1200 | 900×1200 | 750 | 95-165 | 220-380 | 130 | 3789*2826*3025 |

| PE1000 × 1200 | 1000×1200 | 850 | 195-265 | 230-380 | 130 | 3889*2826*3025 |

| PE1200 × 1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 200 | 4930*3150*3700 |

Jaw crusher mainly consists of frame, eccentric shaft, jaw plate, connecting bar, adjustment part, and spring.

The crusher crushes the stone by squeezing, impacting, stripping, rolling, etc.

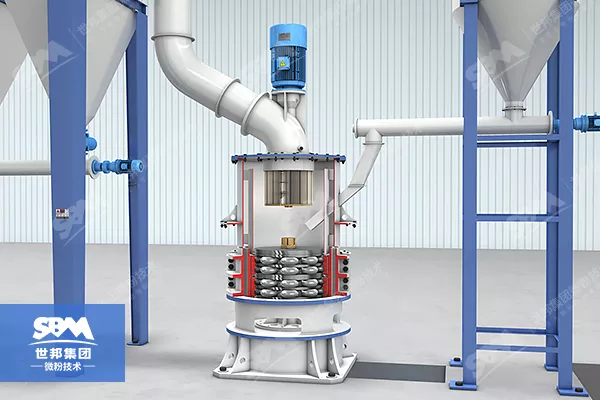

The grinding mill is mainly used to grind the material into ultrafine powder.

Larger mineral materials need to be initially crushed with a crusher. The grinding mill further processes the pulverized material into powder.

CE, ISO9001

Factory sell directly

30 years experience, professional

Sales market all over the world

In the realm of industrial mineral processing, the demand for robust, high-output rock pulverizer machines has never been greater. Among the most advanced solutions in this field is the HGM series of ultrafine grinding mills, engineered to deliver precision, durability, and scalability for large-scale operations. This article delves into the flagship HGM125 model and its…

A ring mill, also known as a ring roller mill, micro powder grinding mill, or ultrafine grinding mill, is a type of grinding equipment commonly used in the industrial production of ultrafine calcium carbonate.

The CLQM series Airflow Vortex Mill Powder Micronizer is designed for processing a wide range of materials, offering uniform particle sizes that can be adjusted according to specific requirements. The CLQM airflow vortex mill powder micronizer is capable of grinding materials to micron and sub-micron levels, making it highly versatile and suitable for processing difficult-to-handle…

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultra-fine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying.

Ultrafine vertical mill is a high-efficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc

Carbon black is a light, loose and fine black powder that contains carbon substances. It can be used as a black dye to make ink, paint, rubber material, etc. Carbon black ultrafine mill is also called (three-ring four-ring) medium-speed ring roller micro-grinding machine. It adopts a graded continuous grinding method to grind the material multiple…

Type: PE150 × 250, PE200 × 350, PE250 × 400, PE400 × 600, PE500 × 750, PE600 × 900

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.