We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorised as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyse the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customised advertisements based on the pages you visited previously and to analyse the effectiveness of the ad campaigns.

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Output Size: 20-100mm

Feed size: <720mm

Capacity: 15-500 t/h

Application: granite, marble, basalt, limestone, quartz stone, river pebbles, iron ore, copper ore, etc.

Jaw crusher is one of the essential crushing equipment in the mining material crushing production line. It is mainly used for medium-sized crushing of various ore materials in mining, smelting, building materials, highways, railways, water conservancy, chemical industry and other industries.

PEW jaw crusher, also known as the European version of the jaw crusher, is suitable for crushing and processing various rocks, ores, slag and other materials with a pressure strength of less than 280MPa. It is the European version of the jaw crusher developed by Shibang Group after the PE series jaw crusher. It is a combination of modern technology and production practice, and is more in line with the automated production needs of our customers.

1. Flywheel

2. Protect plate for movable jaw

3. Eccentric shaft

4. Upper lining plate

5. Fixed jaw plate

6. Movable jaw

7. Movable jaw plate

8. Frame

9. Lower lining plate

10. Adjustment device

11. Toggle plate

12. Tension rod

13. Spring

Durable moving jaw assembly

The moving jaw assembly is made of high-quality cast steel and drove by two massive cast steel flywheels. Avery’s large eccentric shaft forging and four large spherical roller bearings are all of the same size to ensure the greatest reliability even under the most severe crushing conditions.

The right cavity design

The right cavity design can improve the performance of the crusher greatly. The “V” type cavity makes sure the real feeding size of the jaw crusher is equal to the nominal one. The real feeding size of Zenith PEW series is greatly bigger than competitors’ comparable size. This right cavity design ensures that the materials progress smoothly down through the crushing cavity to enable high reduction, productivity, and superb utilization of jaw plates.

Single-piece cast steel frame bearing housings

The single-piece cast steel frame-bearing housings ensure a perfect fit to the crusher frame. They also prevent unnecessary loads to the frame bearings that are common with 2-piece frame bearing housings.

Selected larger eccentric shaft bearing

All SBM PEW series jaw crushers incorporate larger and sturdier eccentric shaft bearings than competitors’ comparable sizes. The grease-lubricated bearings are kept free from contamination by means of well-proven labyrinth seals.

● Stable structure and reliable performance

The bearing seat of the PEW European version of the jaw crusher adopts an integral cast steel structure to avoid unnecessary burdens brought by the two-piece bearing chamber to the frame and improve the stability of the entire machine structure. In addition, the heavy-duty eccentric shaft is processed from forged blanks, making the PEW jaw crusher extremely reliable.

● V-shaped structure, toothed guard plate

The “V”-shaped crushing chamber and tooth-shaped guard plate of the PEW European version of the jaw crusher are designed more rationally to ensure the consistency between the actual feeding size and the theoretical feeding size, effectively increasing the crushing area, and the material does not remain in the crushing chamber. Blockage will occur, which will maximize the crushing rate and output, and improve the utilization rate of the jaw plate.

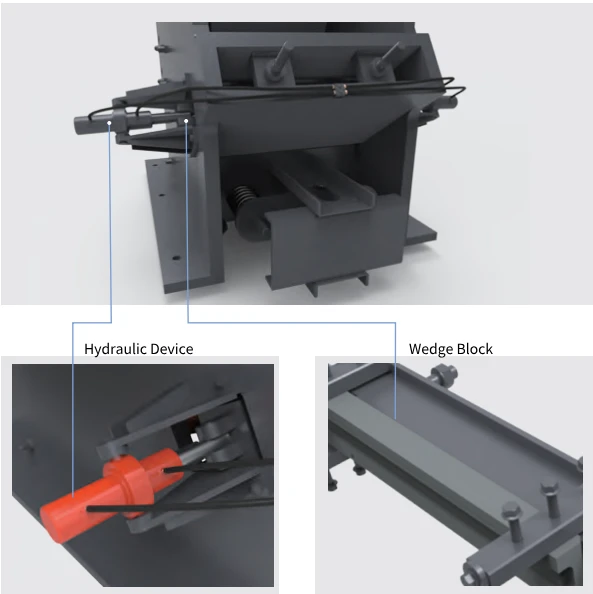

● Hydraulic control, easy to clean the cavity

The PEW European version of the jaw crusher is equipped with a hydraulic oil station to ensure that the machine’s lubrication system supplies oil to the parts that need to be lubricated, ensuring the safe operation of the machine. At the same time, if the crusher shuts down under load, the hydraulic cavity cleaning system can quickly clean the crushing cavity, greatly reducing downtime.

● Wedge device, quick adjustment

The PEW European version of the jaw crusher adopts a wedge discharge opening adjustment system. Even when idling, the discharge port can be adjusted to a predetermined value within a few minutes, and automation can be achieved with the cooperation of the hydraulic system. It is simpler, safer and faster than the old gasket type discharge opening adjustment system.

The crushing method of PEW European version jaw crusher is curved extrusion type. Its working principle is that the electric motor drives the belt and pulley, and the eccentric shaft makes the movable jaw swing back and forth up and down. When the movable jaw pushes the movable jaw plate to move toward the fixed jaw plate, the material is crushed or chopped. When the movable jaw and the movable jaw plate retreat under the action of the eccentric shaft and spring, the previously crushed or chopped materials are discharged from the lower discharge port of the jaw plate. As the motor continuously rotates, the movable jaw of the crusher periodically crushes and discharges materials to achieve mass production.

| Model | Length of feed (mm) | Width of feed (mm) | Maximum feeding size (mm) | Range of discharge opening (mm) | Capacity (t/h) | Speed (r/min) | Power (kw) | Overall dimension (mm) |

| PEW250×1000 | 1000 | 250 | 220 | 20-40 | 15-50 | 330 | 30 | 1400×1850×1310 |

| PEW250×1200 | 1200 | 250 | 220 | 20-40 | 20-50 | 330 | 37 | 1400×2050×1310 |

| PEW400×600 | 600 | 400 | 350 | 35-85 | 15-70 | 250 | 37 | 1920×1460×1840 |

| PEW760 | 1100 | 760 | 640 | 75-200 | 150-350 | 270 | 110 | 2600×2500×2200 |

| PEW860 | 1100 | 860 | 720 | 100-225 | 200-500 | 240 | 132 | 3300×2320×3120 |

| PEW1100 | 1200 | 1100 | 930 | 150-275 | 300-650 | 210 | 185 | 4140×2660×3560 |

PEW jaw crusher

Feed particle size: 0-720mm

Production capacity: 15-500 tons/hour

Applicable materials: granite, marble, basalt, limestone, quartz stone, river pebbles, iron ore, copper ore, etc.

Product features: European version V-shaped crushing chamber, cast-welded frame body, hydraulic double wedge adjustment, electric centralized lubrication

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.