The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Output Size: 0-200 mm

Feed size: 350 mm

Capacity: 90-450 t/h

Application: Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganeseore, refractory material, glass, etc.

The PFW series impact crushers are new high-efficiency hydraulic control impact crushers developed on the basis of international advanced technology for impact crushers, mainly to ease maintenance operation of impact crushers, improve the service life of wearing parts and the equipment performance, and simultaneously reduce the crusher, and simultaneously extend the service life of quick—wear parts, improve device performance and reduce the processing cost of soft materials.

The PFW series impact crushers have innovatively designed the rotors and impact frames, introduced a hydraulic system for adjustment control and top opening operation, and simultaneously developed coarse and intermediate crushing models according to users‘ demands to satisfy different job requirements.

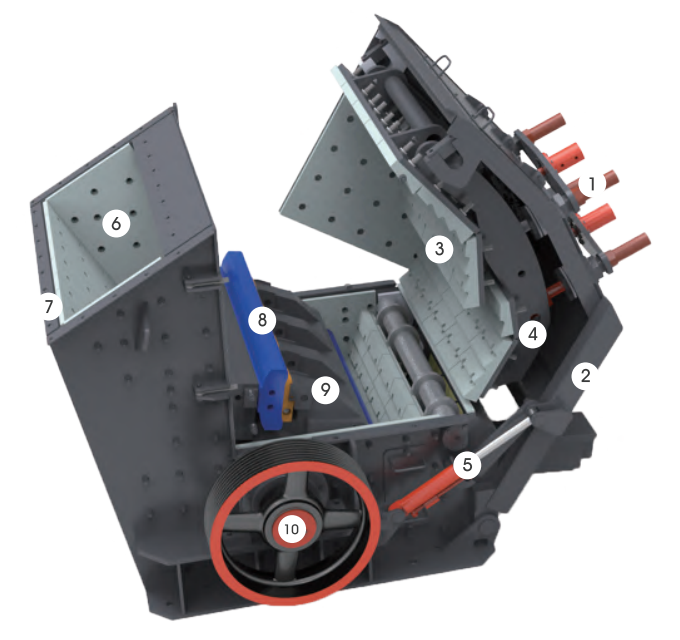

1. Hydraulic regulation device

2. Rear frame

3. Impact plate

4. Impact rear

5. Hydraulic jacking device

6. Lining plate

7. Front frame

8. Hammer bar

9. Rotor

10. Bearing house

● Advanced manufacture process and high—end fabrication material

Key components of the equipment are made of advanced machining and hot treatment processes. Counterattack board is cast by high wear resistant material and the impact face is provided with a lining structure, largely improving the wear resistance property of the impact plate.

Board hammer is poured by the process integrating with highchrome material and wear—resistant material and processed by the rigid thermal treatment, having fine machine impact resistance and thermal impact resistance properties. It makes the fullest use of the hammer bars with symmetric design, which can extend the working life about two times than the old design.

● Heavy rotor design and tight test method

The European style impact crusher adopts a rigid heavy rotor to gain more rotary inertia and counterforce to increase the crushing capacity; and is tested by the tight test method on the defect on the surface, near surface and inner surface to ensure its high quality and improve the rotor performance.

● Overall type cast steel structure bearing base

The overall cast steel bearing base is fully matched with the crusher, and largely increases the radial strength of the bearing base and improves anti load resistance capacity; while the split type bearing base is out of these advantages.

● Reliable wedge fixing mode

The flat hammer of PFW impact crusher is fixed on the rotor by a group of wedge blocks. The wedge block tightly locks the flat hammer from horizontal and vertical directions and needs more fastening torque to enable the flat hammer installed in a simple and convenient way and eliminate abrasions from the flat hammer fixed by bolts.

● Spring safety device

When iron or other hard material that can not be crushed, be fed in the crushing chamber, the front and rear impact shelves will be pushed back, so the hard material will be discharge, the impact crusher resume production and eliminate the blocking risk.

● Hydraulic jacking device and hydraulic regulated discharging port

PFW series impact crusher is installed with hydraulic system at both side. This system can be used for opening the cavity and adjusting the discharge port. It makes changing spare part more easy, reduce time and human labor.

| Model | Rotor Φ×L(mm) | Feed Opening(mm) | Max Feeding(mm) | Capacity(t/h) | Power(kw) | Motor Model | Machine Size(mm) |

|---|---|---|---|---|---|---|---|

| PFW1214II | F1150 × 1400 | 1100 × 1430 | 500 | 130-200 | 4-132 | Y315M-4/132 | 2400 × 2310 × 2550 |

| PFW1315II | F1300 × 1500 | 1200 × 1530 | 600 | 180-320 | 4-160 | Y315L1-4 / 160 | 2700 × 2570 × 2800 |

| PFW1318II | F1300 × 1800 | 1200 × 1830 | 700 | 240-400 | 4-200 | Y315L2-4 / 200 | 2700 × 2870 × 2800 |

| PFW1415II | F1400 × 1500 | 1450 × 1530 | 800 | 240-450 | 4-200 | Y315L2-4 / 200 | 3000 × 2700 × 3070 |

| PFW1214Ⅲ | F1150 × 1400 | 570 × 1430 | 250 | 90-170 | 4-132 | Y315M-4/132 | 2550 × 2310 × 2100 |

| PFW1315Ⅲ | F1300 × 1500 | 625 × 1530 | 300 | 180-270 | 4-160 | Y315L1-4 / 160 | 2960 × 2570 × 2380 |

| PFW1318Ⅲ | F1300 × 1800 | 625 × 1830 | 300 | 220-300 | 4-200 | Y315L2-4 / 200 | 2960 × 2870 × 2380 |

| PFW1415Ⅲ | F1400 × 1500 | 800 × 1530 | 350 | 280-350 | 4-200 | Y315L2-4 / 200 | 3120 × 2650 × 2660 |

Note: This specification is just referencing, any changes are subject to the products.

Model: PFW

Accepted delivery terms: FOB, CFR, CIF, EXW, CPT, DDU, express

Acceptable payment currency: USD

Acceptable payment methods: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.