The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

03/11/2021 admin

Phosphate rock is an important support for the phosphorous chemical industry. Phosphate mineral powder grinding mills are processing equipment for phosphate rock powders. Choosing a high-efficiency, intelligent, energy-saving, and environmentally friendly phosphate rock powder mill can greatly enhance the market competitiveness of phosphate rock powders and create more great value.

SBM is an excellent manufacturer of ore crushers and mills in China, specializing in the development and production of ore milling machinery. At present, for the field of non-metallic ore, there are ultrafine grinding mills, micro-pulverizers, superfine vertical roller mills, wet mills, and other industrial ore grinding equipment. It can be applied to different operating environments to meet different production needs.

Phosphate rock is a phosphate-hydrochloric acid mineral-rich in phosphorus, mainly represented by apatite. Based on phosphate rock, it can produce phosphate fertilizer, yellow phosphorus, and phosphide, phosphoric acid and phosphate, etc. The phosphorus chemical industry involves many industries, such as agriculture, medicine, national defense, metallurgy, coatings, textiles, daily chemicals, ceramics, paper, glass, ammunition, etc.

With the continuous development of technology and economy, the application of phosphorus chemical products has gradually deepened, and high-purity and high-precision products have been promoted and applied in cutting-edge science and the national defense industry. Such as electronic and electrical materials, sensor element materials, catalysts, artificial biological materials, optical materials, etc. Correspondingly, it is the higher standard requirement of phosphate rock powder grinding and purification technology.

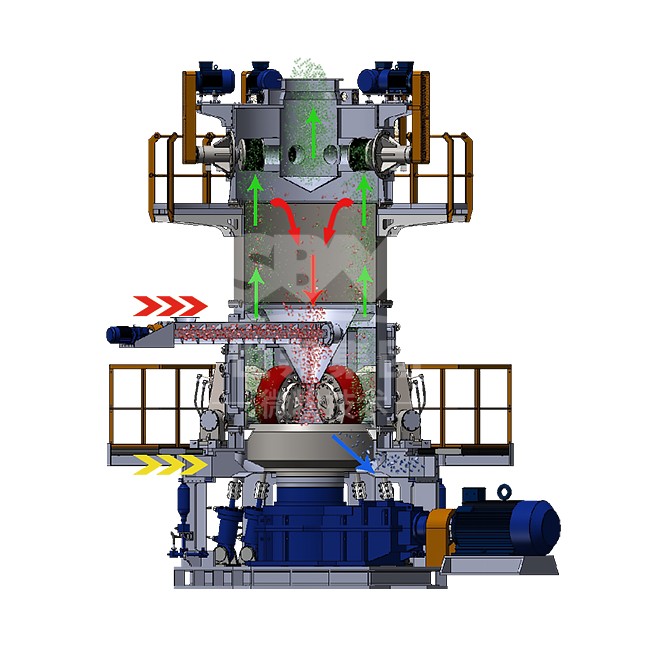

Phosphate ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation.

In the crushing process, the three-stage closed-circuit crushing is more modern and suitable for the crushing of high-hardness phosphate ore. It can complete the crushing and partial dissociation of the ore, thereby improving the subsequent grinding efficiency.

In the grinding process, the two-stage and one-closed grinding is an efficient grinding process, which can make the phosphorus ore grind more fully.

In the beneficiation process, the direct flotation process, reverse flotation, scrubbing sludge, heavy medium separation, and other process methods.

The first stage: the crushing of raw materials

Large chunks of phosphate ore are evenly sent to the jaw crusher (primary crushing) by the vibrating feeder through the silo for coarse crushing.

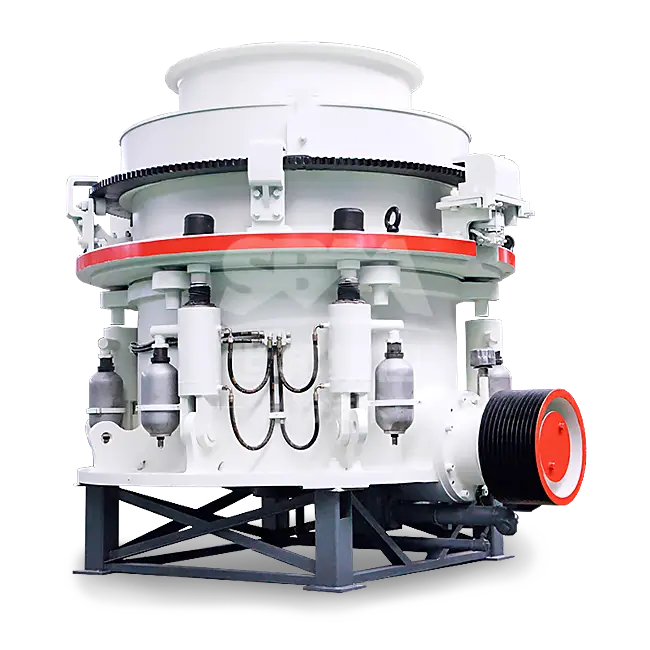

After the coarsely crushed phosphate rock is screened by a vibrating screen, it is sent to a single-cylinder hydraulic cone crusher (medium crushing) by a belt conveyor for medium crushing.

The medium crushed phosphate ore materials are sent to a multi-cylinder hydraulic cone crusher for fine crushing.

The second stage: milling

The crushed small phosphate ore materials are sent to the storage hopper by elevator and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

The third stage: classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

The fourth stage: the collection of finished products

The powder that conforms to the fineness is separated and collected in the dust collector through the pipeline with the airflow, and the collected product powder is sent to the finished product silo through the discharge port by the conveying device.

The fourth stage: magnetic selection

Send the phosphorous powder that meets the beneficiation requirements into the flotation machine for flotation to remove impurities

The fifth stage: drying

Phosphorus can be obtained through subsequent processes.

The equipment configuration of the complete phosphate powder production line is complicated, and the equipment selection can be planned and adjusted according to the actual production needs of customers, and the production line has a high degree of automation. The milling link in the production line is extremely important. Only by selecting the right equipment can we produce phosphate powder that meets the requirements, and can maximize efficiency and reduce energy consumption, so as to obtain ideal profits.

Jaw crushers are widely used as crushing equipment in the phosphate grinding production line. It is mainly used for the primary crushing operation of the raw material phosphate so that the crushed phosphate meets the particle size requirements required by the next construction. The equipment has the characteristics of a small footprint, simple operation, convenient maintenance, large processing capacity, energy-saving, and consumption reduction.

The cone crusher is excellent in crushing hard materials. The stable lubrication system and the excellent sealing system have significantly reduced the production cost. The overload protection system can effectively ensure the safety of the crusher. Using different crushing cavities and adjusting devices, it is easy to control the discharging particle size.

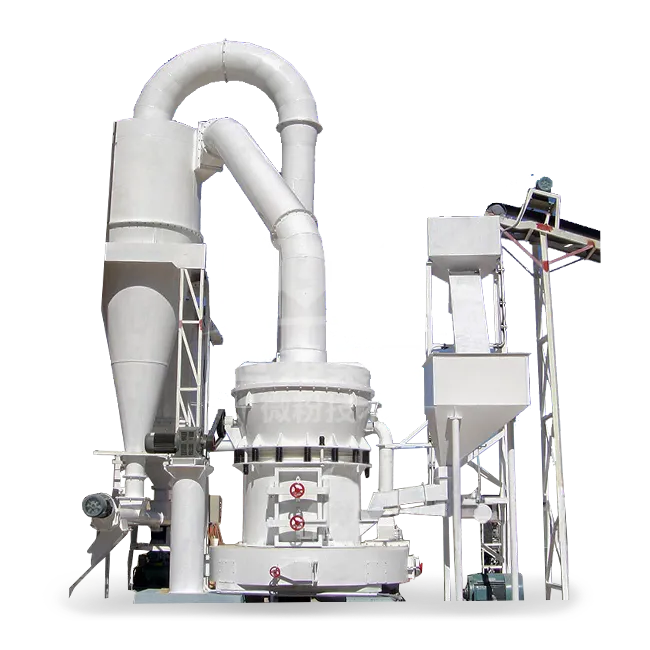

There are many models of phosphate rock powder mills. CLUM vertical roller mills, HGM ultrafine grinding mills, high-pressure mills, Raymond mills, etc. are all powerful tools for processing phosphate rock. Each series of pulverizers has different models, and suitable phosphate ore production lines can be configured for different capacity requirements. The production capacity ranges from a few tons to dozens of tons, and the fineness of the finished product can be adjusted from 80 mesh to 3000 mesh, high efficiency, and energy-saving, consumption reduction and environmental protection, simple operation, and convenient maintenance. The following is a detailed look at the technical parameters of different types of equipment.

>> 150-3000 mesh powder

Product features: ultrafine powder, wide application, the good environmental protection effect

Input size: 0-20mm

The fineness of the product: 150-3000mesh

Capacity: 0.5-25TPH

Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

HGM superfine powder mill

The newly designed grinding roller grinding ring grinding curve improves the grinding efficiency. The production capacity is 40% higher than that of jet mills and stirring mills, and the energy consumption is only 30% of that of jet mills.

Equipped with multi-head cage type powder concentrator. The fineness of the product can be adjusted arbitrarily between 150-3000 mesh, and the one-time screening rate can reach d97≤5μm.

The lubrication device is installed outside the main shaft, which can realize external non-stop lubrication and continuous production for 24 hours.

HGM ultrafine grinding mill is equipped with a high-efficiency pulse dust collector, so there will be no dust pollution during the operation of the entire crushing system. Equipped with silencer and anechoic room to reduce noise.

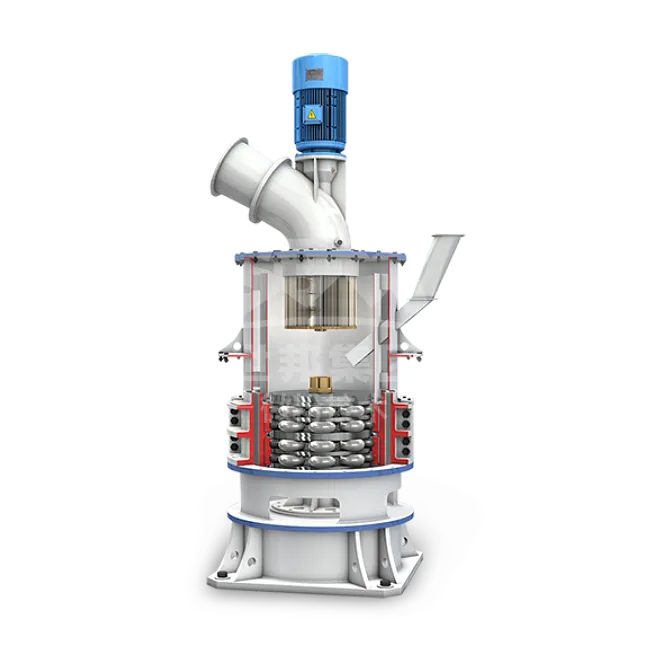

Product features: higher capacity, better powder quality, better overall performance

Input size: 0-10mm

Capacity: 5-18TPH

The fineness of the product: 150-3000mesh

Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

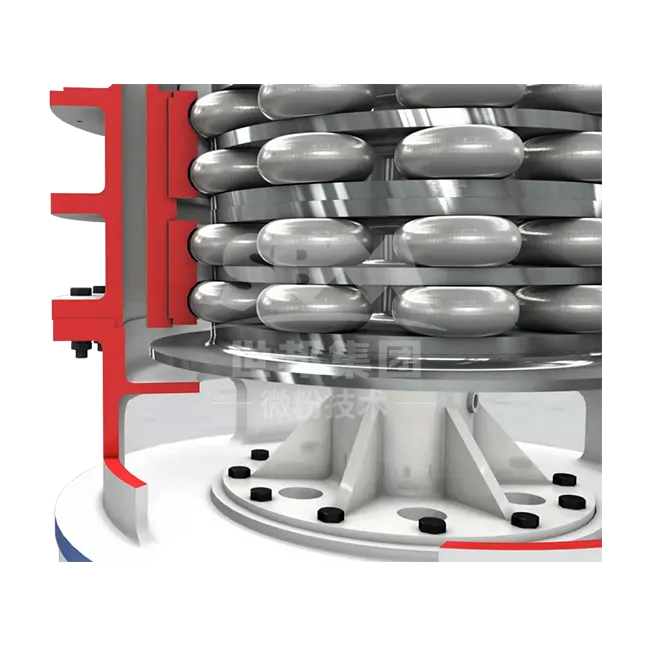

CLUM ultrafine vertical roller mill

SBM specially designed a unique roller shell and liner grinding curve, which can greatly improve the working efficiency of the mill and improve the whiteness and cleanliness of the finished product.

Using a PLC control system and multi-head powder selection technology, it can precisely control the working parameters of the equipment such as grinding pressure and speed. Compared with ordinary mills, the energy consumption of this mill can be reduced by 30%-50%.

The contact point between the roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive impact caused by machine vibration and ensure the stability of operation.

Through the reversible structure and hydraulic adjustment system, the operator can easily and quickly move the grinding roller out of the machine body, inspect and replace the roller shell and liner, and perform other maintenance operations to reduce downtime losses.

>> 50-325 mesh powder

Processing ability: 0-50tph

Max feeding size: 35mm

Product Fineness: 80-325Mesh

Range of application: Barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, marble, granite, fly ash, kaolin, calcium carbonate, slag, bauxite, glass, etc.

High-pressure Powder Mill

Vertical structure, so it has a small footprint, strong system. Compared with other mills, it has a high passing rate – 99%.

The main drive device of the high-pressure mill adopts an airtight gearbox and belt pulley, the transmission is stable and the operation is reliable.

Important components are made of high-quality castings and profiles, ensuring the durability of the whole equipment.

The centralized control is used in the electric system, the mill can basically realize unmanned operation, and the maintenance is convenient.

SBM provides non-metallic ore grinding/crushing and screening solutions.

The common choice of 1000+ customers, tailor-made solutions for you.

More than 30 years of R&D and manufacturing experience, covering 120+ countries and regions, witnessing high quality together.

Systematic and standardized process, from service to preparation and delivery, safer and more efficient.

The production capacity is strong, and the production department adopts digital processing with higher precision. The supply of spare parts is sufficient, and the operation is worry-free.

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

Phosphorus powder is a kind of phosphate rock powder. Phosphate rock powder is a representative species of relatively insoluble phosphate fertilizer. Phosphate powder can be produced by grinding phosphate rock.

Phosphate rock powder generally cannot be used directly. The phosphate rock powder that can be used directly is a variety that contains a relatively high amount of weakly acidic phosphate, but not all phosphate rock can be ground and used directly as a phosphate fertilizer.

The main component of phosphate rock powder is tricalcium phosphate or fluorinated calcium phosphate, with a phosphorus content of more than 14%. The level of phosphorus content is determined by the taste of the phosphate rock.

Phosphate rock powder is more suitable as base fertilizer on acid soil, but it cannot be used as a top dressing. The amount of phosphate rock powder used as base fertilizer should be determined by the content of phosphate rock powder.

Reasonable and correct use of phosphate rock powder can not only increase the yield of crops and improve the quality of crops but also make the grains of cereal crops full, such as promoting the flowering and fruiting of cotton, melons, solanaceous vegetables, and fruit trees.

Phosphate rock powder mainly depends on the acidity in the soil, soil microorganisms, weak acid secreted by crop roots, etc. to be transformed, and then absorbed and utilized by crops.

Mineral phosphate powder is the kind of fertilizer that absorbs relatively slowly. It can maintain a fertilizer effect for several years after one use.

The washing powder contains phosphorus compounds, which can combine with the calcium and magnesium ions in the water to reduce the hardness of the water, thereby improving the decontamination effect.

Apatite refers to phosphorous ore in which phosphorus exists in igneous and metamorphic rocks in the form of crystalline apatite. It is the general term for a series of calcium-containing phosphate minerals. The shape of apatite is glass-like crystals, blocks or nodules, with various colors, mostly hexagonal cylinders with cones. The Moss hardness is 5, and the specific gravity is 3.18~3.21. Phosphorescence can often appear after heating.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.