Foundation Requirements:

1. Construct a robust concrete foundation that can withstand dynamic forces during operation.

2. Dimensions should allow space for ancillary equipment like blowers and classifiers.

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Material: coal

Fineness: 80-400mesh

Capacity: 12 t/h

Purpose: Power Plants: Produces fine coal powder for efficient combustion in boilers. Cement Plants: Provides fuel-grade coal powder for kilns. Chemical Industry: Used as a raw material for various chemical processes.

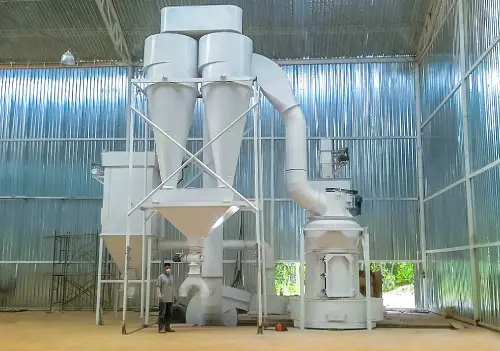

This Coal Powder Making Plant in Bhutan utilizes our CLRM1300 Raymond grinding mill to achieve 80-400 mesh coal powder production with high capacity.

The customer celebrated the factory’s commencement with prayers for a bright and successful future.

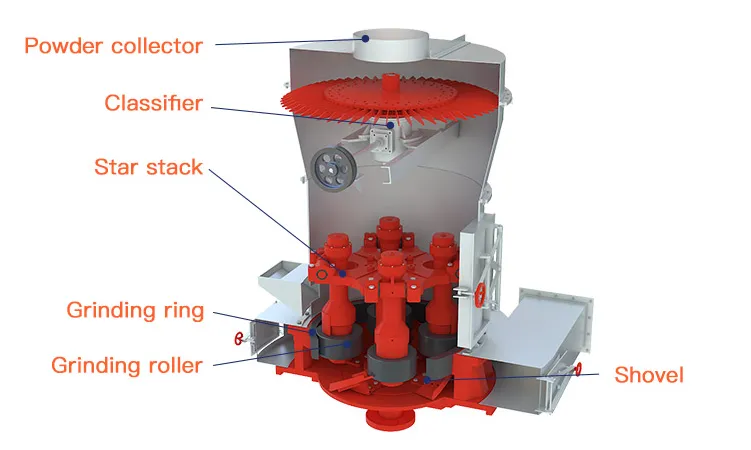

The Raymond mill is widely used for grinding coal into fine powder, making it ideal for use in industries such as power generation, cement manufacturing, metallurgy, and chemical processing.

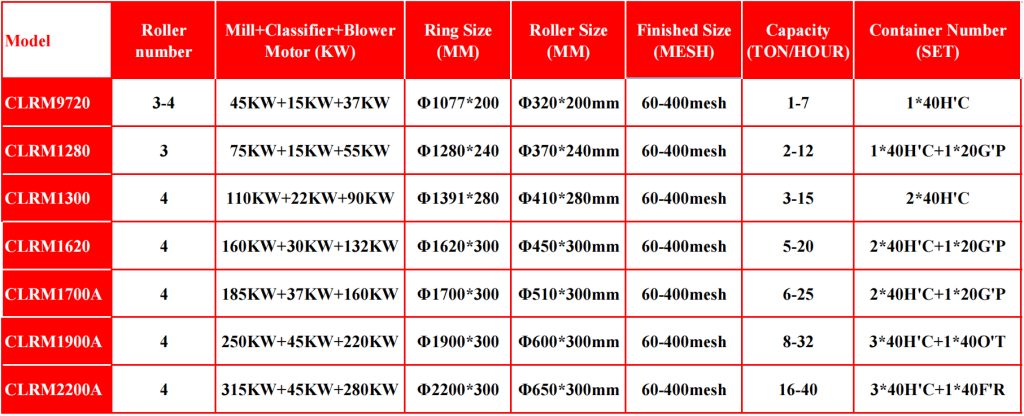

For coal powder production, your choice of Raymond Mill depends on the required capacity and application. Below are recommendations:

1. Construct a robust concrete foundation that can withstand dynamic forces during operation.

2. Dimensions should allow space for ancillary equipment like blowers and classifiers.

1. Ensure stable 3-phase industrial power supply (380V, 50Hz).

2. Use appropriate circuit breakers and surge protectors.

1. Install the mill indoors or under a covered structure to protect from environmental damage.

2. Allow for easy access to feeders, dust collectors, and maintenance areas.

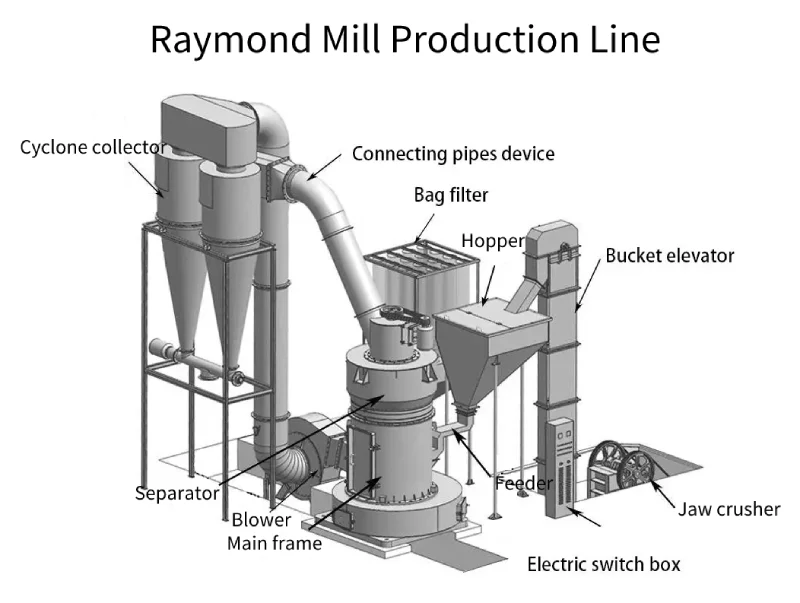

1. Use a vibrating feeder for consistent coal supply to the grinding chamber.

2. Pre-screen the coal to remove oversized particles (>30 mm).

1. Install a high-efficiency pulse dust collector to comply with environmental standards.

2. Position it downstream of the cyclone separator for maximum efficiency.

1. Perform a dry run before feeding coal.

2. Gradually introduce coal to check for system stability.

3. Monitor motor loads, temperature, and airflow rates to ensure optimal performance.

1. Install explosion-proof devices for handling coal powder, which is highly combustible.

2. Ensure proper grounding and regular checks for leaks in dust handling systems.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.