The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Output Size: 2-150 mm

Feed size: 36-1000 mm

Capacity: 3-250 m³/h

Application: fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker...

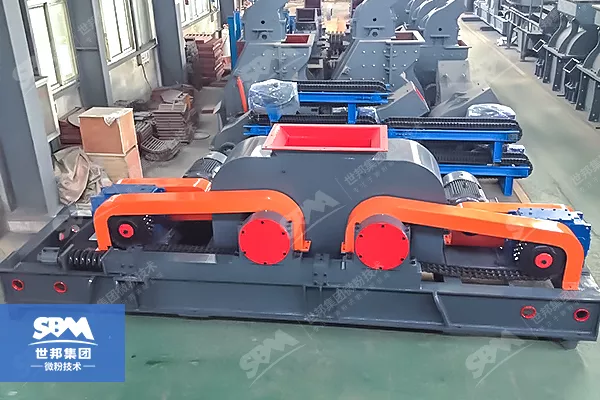

The heavy-duty roll crusher is a type of industrial machine used to crush large, hard materials into smaller pieces. These machines are typically used in industries such as mining, metallurgy, cement, recycling, and power generation for processing materials like ore, coal, limestone, and other aggregates.

Heavy-duty roll crusher is also named roller crusher or tooth roller crusher. The most commonly used one is the crusher with two rollers, it is called double roller crusher or twin roller crusher.

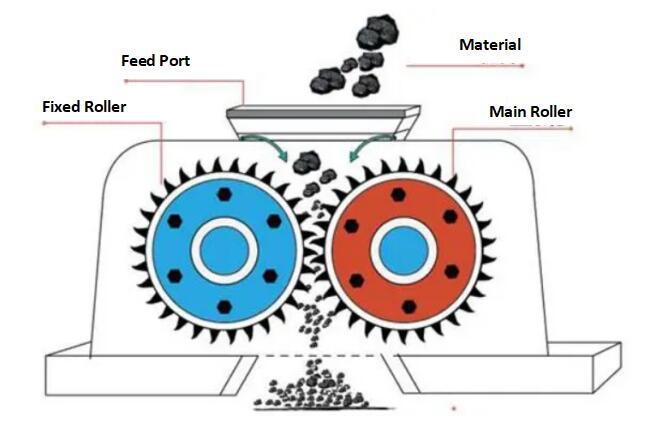

Roll crusher is mainly composed of the roller, the roller support bearings, the compaction and adjusting device, and driving unit, and other parts.

The roller crusher operates by squeezing materials at low rotating speed and high pressure. Materials fall vertically into the crushing chamber from the top of the crusher and are crushed between two rollers. Due to gravity, the crushed materials are discharged through the gap between the rollers. The discharging size can be adjusted using either a wedge or gasket adjustment device.

In the wedge adjustment device, an adjusting bolt at the top pulls the wedge upward to push the movable roller away from the fixed roller, increasing the gap and the discharging size. Lowering the wedge reduces the gap and the discharging size. The gasket adjustment device works by adding or removing gaskets. Adding gaskets increases the gap between the rollers, resulting in larger discharging granularity, while removing gaskets decreases the gap and the discharging granularity. These adjustment mechanisms ensure precise control over the size of the discharged materials.

Mining: Crushing of ores to extract valuable minerals.

Cement Industry: Crushing limestone and other materials to produce cement.

Power Generation: Reducing coal to a size suitable for burning in power plants.

Recycling: Crushing materials like concrete and asphalt for reuse.

High Capacity: Capable of processing large volumes of material.

Durability: Built to handle tough materials and harsh working conditions.

Adjustability: Gap settings can be adjusted for different material sizes.

Efficiency: Often designed to minimize fines and produce a uniform particle size.

A double roller crusher, also known as a double roll crusher or twin-roll crusher, is a type of crusher that features two parallel rollers mounted horizontally in a frame. These rollers rotate in opposite directions, crushing material between them. Double roller crushers are commonly used in the processing of various materials, including coal, limestone, clay, shale, and more.

Two parallel rollers that rotate in opposite directions.

Each roller typically has a series of teeth or ridges that grip and crush the material.

The distance between the rollers can often be adjusted to control the size of the crushed material.

Material is fed into the gap between the rollers by gravity or by a conveyor belt.

The rollers pull the material into the crushing zone where it is compressed and sheared.

Typically powered by electric motors, although hydraulic drives are also used in some applications.

Double rollers crush material more efficiently compared to single rollers, as the material is crushed twice during each rotation.

The adjustable gap allows for precise control over the size of the crushed material, resulting in a uniform particle size distribution.

Suitable for a wide range of materials, including coal, limestone, clay, and more.

Can handle both primary and secondary crushing duties.

Occupies less space compared to other types of crushers, making it suitable for installations with space constraints.

Coal Processing

Double roller crushers are commonly used in coal preparation plants to crush coal to a desired size for combustion.

Limestone and Clay Crushing

Used in cement plants and quarries to crush limestone, clay, shale, and other raw materials for cement production.

Minerals Processing

Used in various mineral processing applications to crush ores and minerals to a suitable size for further processing.

Recycling

Can be used to crush recycled materials such as concrete, asphalt, and bricks for reuse in construction projects.

| Type | Model | Input Size(mm) | Output Size(mm) | Capacity(m³/h) | Power(kw) | Dimenstion(mm) | Weight(kg) |

| Double Roll Crusher | 2PGQ 610*400 | < 36 | 2-9 | 3-9 | 22 | 1785*2365*1415 | 3800 |

| 2PGQ 750*500 | < 40 | 2-10 | 5-12 | 18.5*2 | 2720*2700*1400 | 10800 | |

| 2PGQ 750*700 | < 40 | 2-10 | 6-16 | 22*2 | 2800*3987*1705 | 12200 | |

| 2PGQ 900*500 | < 40 | 2-10 | 9-30 | 22*2 | 2750*1790*2065 | 15000 | |

| 2PGQ 900*900 | < 40 | 2-10 | 11-45 | ~ 37*2 | 2750*2180*2065 | 16800 | |

| 2PGQ 900*1200 | < 40 | 3-10 | 15-60 | ~ 55*2 | 2750*2480*2065 | 20800 | |

| 2PGY 1200*1000 | < 40 | 3-12 | 10-50 | 55*2 | 3690*3430*2700 | 46820 | |

| 2PGY 1200*1200 | < 40 | 3-12 | 18-68 | ~ 75*2 | 3690*3630*2700 | 48600 | |

| Four Roll Crusher | 4PG750*500 | 30-60 | 2-10 | 3-10 | 18.5+11/17 | 2760*3585*2650 | 19200 |

| 4PG900*700 | 40-100 | 2-10 | 16-20 | 30+12/24 | 3150*4175*3147 | 28700 | |

| 4PG900*900 | 40-100 | 2-10 | 20-25 | 45×2 | 3150*2650*3147 | 31386 | |

| 4PGY1200*1000 | 20-40 | 3-10 | 43-68 | 75+40/55 | 5410*5600*3600 | 67000 | |

| Double-geared Roller Crusher | 2PGC450*500 | 100-200 | 25-100 | 12-32 | <11 | 2260*2206*766 | 3100 |

| 2PGC600*750 | 300-600 | 50-125 | 50-75 | <22 | 3265*2850*1310 | 7400 | |

| 2PGC900*900 | <800 | 75-150 | 60-110 | <30 | 3945*3405*1895 | 13670 | |

| 2PGC920*1200 | <800 | 40-100 | 90-150 | <75 | 3848*3480*1394 | 16730 | |

| 2PGC1200*1500 | <1000 | -100 | 150-250 | 2*55 | 8010*4050*2050 | 52000 |

| Type | Model | Input Size(mm) | Output Size(mm) | Capacity(m³/h) | Power(kw) | Dimenstion(mm) | Weight(kg) |

| Double Roll Crusher | 2PGQ 610*400 | < 36 | 2-9 | 3-9 | 22 | 1785*2365*1415 | 3800 |

| 2PGQ 750*500 | < 40 | 2-10 | 5-12 | 18.5*2 | 2720*2700*1400 | 10800 | |

| 2PGQ 750*700 | < 40 | 2-10 | 6-16 | 22*2 | 2800*3987*1705 | 12200 | |

| 2PGQ 900*500 | < 40 | 2-10 | 9-30 | 22*2 | 2750*1790*2065 | 15000 | |

| 2PGQ 900*900 | < 40 | 2-10 | 11-45 | ~ 37*2 | 2750*2180*2065 | 16800 | |

| 2PGQ 900*1200 | < 40 | 3-10 | 15-60 | ~ 55*2 | 2750*2480*2065 | 20800 | |

| 2PGY 1200*1000 | < 40 | 3-12 | 10-50 | 55*2 | 3690*3430*2700 | 46820 | |

| 2PGY 1200*1200 | < 40 | 3-12 | 18-68 | ~ 75*2 | 3690*3630*2700 | 48600 | |

| Four Roll Crusher | 4PG750*500 | 30-60 | 2-10 | 3-10 | 18.5+11/17 | 2760*3585*2650 | 19200 |

| 4PG900*700 | 40-100 | 2-10 | 16-20 | 30+12/24 | 3150*4175*3147 | 28700 | |

| 4PG900*900 | 40-100 | 2-10 | 20-25 | 45×2 | 3150*2650*3147 | 31386 | |

| 4PGY1200*1000 | 20-40 | 3-10 | 43-68 | 75+40/55 | 5410*5600*3600 | 67000 | |

| Double-geared Roller Crusher | 2PGC450*500 | 100-200 | 25-100 | 12-32 | <11 | 2260*2206*766 | 3100 |

| 2PGC600*750 | 300-600 | 50-125 | 50-75 | <22 | 3265*2850*1310 | 7400 | |

| 2PGC900*900 | <800 | 75-150 | 60-110 | <30 | 3945*3405*1895 | 13670 | |

| 2PGC920*1200 | <800 | 40-100 | 90-150 | <75 | 3848*3480*1394 | 16730 | |

| 2PGC1200*1500 | <1000 | -100 | 150-250 | 2*55 | 8010*4050*2050 | 52000 |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.