The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <25 mm

Output: 0.5-45 T/H

Product features: High efficiency and low consumption Environmental protection Easy to operation Small footprint

Stone powder making machine is an industrial grinding mill that can grind solid materials into ultrafine powder. It is usually used in metallurgy, building materials, chemical, and mine industries.

It is suitable for the superfine grinding of all kinds of crisp materials whose Moh’s hardness is below 7, such as calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, white mud, mica, refractory material, glass, total about 1000 kinds of materials.

Finished production fineness: 250meshes-2500meshes, 5-74 micron.

The capacity (ton/hour) ranges from 0.4T/H to 45T/H.

Max feeding size: 20 mm.

● High efficiency

Under the same finished final size and the same motor power, the capacity of the zeolite grinding machine is twice as much as jet mill, mixing grinder, and ball mill.

● Long lifecycle of spare parts

● High safety and reliability

As no rolling bearings or screws in the grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

● High fineness and flexible adjustment

● Environment-friendly

The application of pulse deduster and muffler greatly alleviates dust pollution and noise.

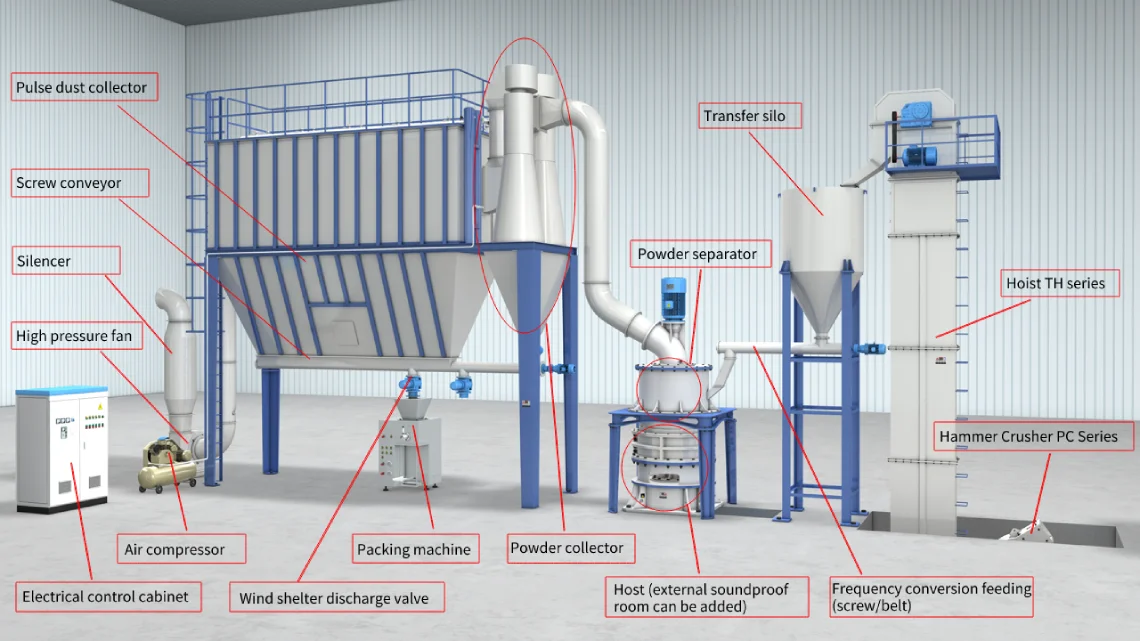

Stone powder making machine is mainly formed by mill body, blower fan, ultra-fine analyzer, finished product cyclone container, bag de-duster, and air pipe. The elevator, storage bin, electric control cabinet, powder feeder, and crusher are optional for the demands of customers.

Ultrafine grinding mill host

Hoist

Packing machine gas conveying

Superfine grinding mill dust collector powder collector

Superfine grinding mill tank

Packing Machine

After being crushed by hammer crusher, the big materials become small ones and are sent to storage hopper by elevator and further sent to the middle of the first dial evenly by the electromagnetic vibrating feeder and feeding pipe.

The materials will be driven to the edge of the dial by centrifugal force and fall down into the ring, crushed and ground by roller, and become powder after production of three rings.

The high-pressure centrifugal blower will inhale air from outside and blow the crushed materials to the classifier.

The rotating turbo in the powder concentrator will make the coarse powder return to the mill and reground, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it.

The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

① Integrated design, less comprehensive investment

The machine integrates crushing, grinding, powder selection, conveying, and packaging. The system is simple, and the layout is compact. The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costs. The system design is simple and reasonable, saving unnecessary equipment investment and reducing the total equipment investment.

② 24-hour continuous production without stopping

The grinding roller bearings and reducer of the main machine are all lubricated with thin oil, which can be used for 24-hour continuous production without stopping. The lubrication system is stable and reliable, and the maintenance is simple.

③ Intelligent control, simple and safe

Adopting PLC/DCS automatic control of grinding roller pressure control mode, basically no manual operation is required. The independent grinding roller lubrication station can not only fully lubricate but also prevent excessive oil leakage.

④ Using multi-head powder separator

Using the principle of multi-wheel powder selection, all rotors can be adjusted by frequency control, and the fineness of finished products can be realized within the selected range. The quality of multi-variety production is stable, and the reproducibility is high.

⑤ Environmentally friendly

The equipment is sealed as a whole, the system works under negative pressure, and the finished product is directly sent to the large finished product warehouse by the gas conveying equipment, without dust spillage, the production environment is clean and meets the environmental protection requirements.

⑥ Adapt measures to local conditions, plan optimization

The production line construction plan is designed by the professional team of SBM micro-powder technology according to the data of the field examination room and combined with the production needs of customers, and the production and operation process is smooth.

| Parameters of HGM series ultrafine mill | |||||||

|---|---|---|---|---|---|---|---|

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Crushing system: raw material silo→feeder→jaw crusher→belt conveyor→de-ironing separator→hammer crusher→elevator→dust collector→surge bin.

Grinding system: quantitative belt scale→elevator→spiral conveyor→de-ironing separator→ultrafine vertical mill→pulse dus collector→fan→air door.

Conveying system: elevator or pneumatic conveyor.

Auxiliary system: agent adding system, compressed air system, water cooling system.

CE, ISO9001

factory sell directly

30 years experience, professional

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Unio

A ring mill, also known as a ring roller mill, micro powder grinding mill, or ultrafine grinding mill, is a type of grinding equipment commonly used in the industrial production of ultrafine calcium carbonate.

The HGM ultrafine grinding mill is an excellent choice for grinding plagioclase to ultrafine powder. This mill is known for its high efficiency, precise control over particle size, and capability to produce extremely fine powders. Below is a detailed overview of the HGM ultrafine grinding mill, including its features, benefits, and specific application for plagioclase…

Choosing the right stone powder grinding mill for your needs is crucial in achieving optimal performance and efficiency in your operations. This detailed guide will help you understand the different types of grinding mills available, their features, applications, and how to select the most suitable one for your specific requirements. Stone powder grinding mills are…

Orthoclase powder making machines are a collection of specialized equipment designed to crush, grind, and process orthoclase minerals into finely ground powders, crucial for various industrial applications such as ceramics, glass manufacturing, and construction materials.

Crushing and grinding machines are used to reduce the size of the shale particles and prepare them for further processing.

The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, energy-saving capabilities, and ability to produce fine and ultrafine powders.

Model: HGM80, HGM90, HGM100, HGM125, HGM168L

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.