The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 1-20 T/H

Product features: higher capacity, better powder quality, better overall performance, a series of energy-saving, drying, and grinding functions.

The talc powder ultrafine vertical mill has stable operation, large output, the finished powder has high whiteness and good shape. It is intelligent, efficient, energy-saving, and environmentally friendly industrial milling equipment. It can grind talc up to 3000 mesh, and the fineness can be adjusted between 150-3000 mesh. The talc ultra-fine vertical mill can also be used to process other non-metallic ores (barite, kaolin, gypsum, carbon black, etc.), shells, bamboo, etc.

The CLUM ultrafine vertical mill is independently developed by SBM on the basis of many years of experience in mill production. Integrating ultrafine grinding, grading, and conveying, has become a better choice in the ultrafine grinding industry.

Output: 1-20TPH

Adjustable fineness: 150-3000 mesh

Processable materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

Features: higher capacity, better powder quality, better overall performance, a series of energy-saving, drying, and grinding functions.

Talc is a common silicate mineral, generally, in the block, leaf, fibrous or radial shape, and the color are white and off-white. It has a wide range of uses.

After being milled, its application value is greatly enhanced, such as various emollient powders and talcum powders in cosmetics.

Pharmaceutical tablets, powders, food additives, release agents, etc. White extender paint, primer, protective paint, etc. for coating products.

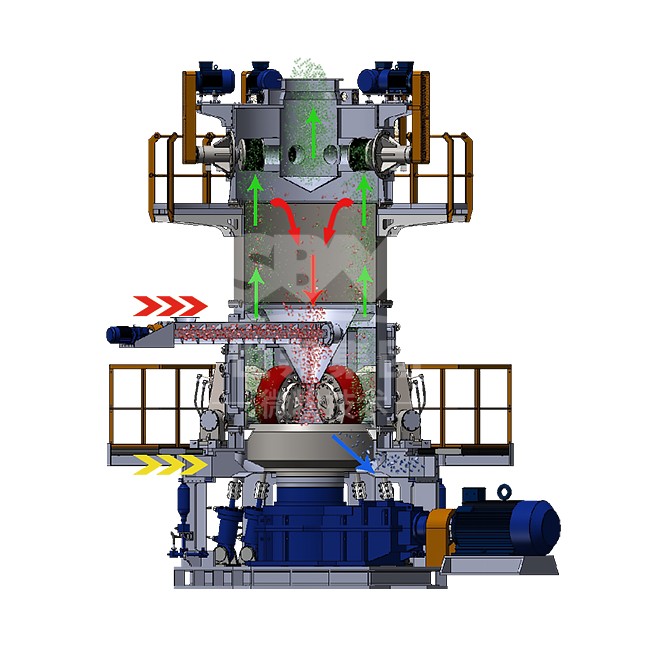

The ultrafine vertical mill system is composed of a host, a feeder, a classifier, a blower, a pipeline device, a storage hopper, an electric control system, and a collection system.

The material falls to the center of the CLUM ultrafine vertical grinding disc through the screw feeder. Driven by the host motor, the reducer drives the grinding disc to rotate, forming centrifugal force, forcing the material to move to the edge of the grinding disc.

When passing through the grinding zone between the drum and the grinding disc, the bulk material is directly crushed under the pressure of the drum. The fine-grained materials form a layer, and the materials crush each other.

The crushed material after pulverization continues to move to the edge of the grinding disc until it is carried away by the airflow and enters the powder separator. Under the action of the powder separator blade, the coarse particles that do not meet the fineness standard fall into the grinding disc for re-grinding, and the powder that meets the standard enters the powder collector as a finished product.

For the iron and other debris in the material, when they move to the edge of the grinding disc, they will fall into the lower cavity of the mill due to their heavyweight, and then be sent into the discharge port by the scraper installed at the bottom of the mill and finally discharged out of the mill.

① High grinding efficiency. Adopting the principle of material bed squeezing and crushing, the material is crushed, sheared, and impacted in the mill. The airflow in the mill can bring out the ground materials in time to avoid over-grinding.

② High drying efficiency. Hot air is sprayed from the annular slit, the wind speed is high, the ventilation section in the mill is large, and the resistance is small.

③ The granularity of the material to be milled is large, the equipment process performance is good, the single machine output is large, and the equipment operation rate is high.

④ The process flow is simple, the operation is intelligent, the daily maintenance is convenient, and the service life is long.

⑤ The overall airtight performance is good, the dust is small, the noise is low, and the working environment is good.

⑥ The granularity of the finished product can be adjusted flexibly, which facilitates the realization of intelligent and automated operations.

CLUM ultrafine vertical roller mill, talc powder ultrafine vertical mill

The talc ultrafine vertical mill, CLUM ultrafine vertical mill, with a capacity of 4-40 tons per hour, can produce ultrafine talcum powder from 150 mesh to 3000 mesh. Using new classification technology, multi-head fine powder analysis system. Using modern new technology electrostatic pulse dust removal system, the dust removal rate is 96%, environmental protection, and pollution-free.

CLUM talc powder ultrafine vertical mills can process high-end powders in the powder industry, thereby bringing more returns to customers. If you need to grind talc fine powder from 150 mesh to 3000 mesh, then the CLUM ultrafine vertical mill is the most accurate choice.

Model: CLUM

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.