We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorised as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyse the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customised advertisements based on the pages you visited previously and to analyse the effectiveness of the ad campaigns.

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Capacity: 15.77-210 m³/h

Max feeding size: 30-60 mm

Processing ability: 15.77-210 m³/h

Application: Ore, coal, cement chamotte, foodstuff, and so on

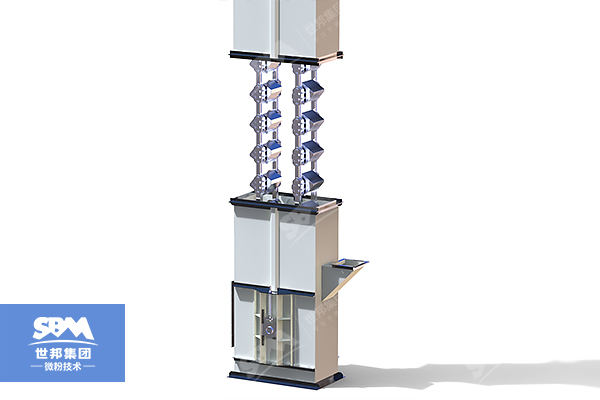

The TH bucket elevator is a kind of vertical conveying equipment, widely used in conveying powder, granule, and a small lump of no rub or small rub (material temperature under 250 ℃). Such as coal, cement, gravel, sand, fertilizer, food, etc.

The main performance and parameters meet the JB3926-85 vertical bucket elevator. The round-link chain accords with MT36-80 mineral high strength round-link chain.

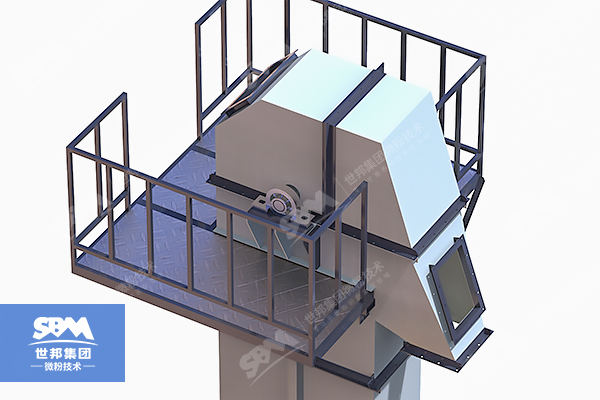

The bucket elevator consists of frame, drag part (conveyor chain), hopper, drive wheel (head wheel), feeding inlet (input inlet), and discharging outlet (output outlet).

The materials get into the bottom of the elevator through the chute, then scooped up by hoppers and elevated to the top along with the conveying chain.

After getting around the top wheel, the materials turn down into the discharging outlet, thereby conveyed to the required position. The whole process is accomplished inside the frame, preventing the dust from floating.

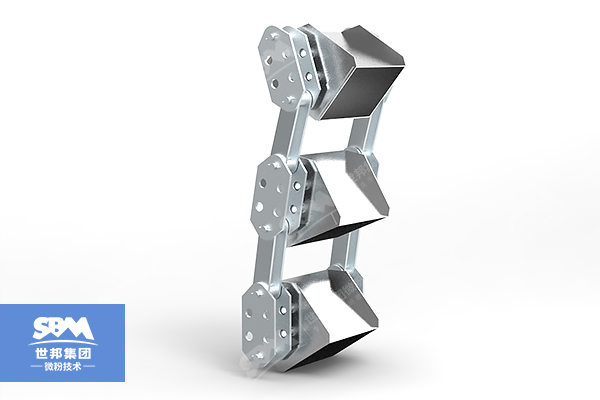

The drag part uses high strong high-quality alloy steel chain. The sprocket wheel with the sprocket rim composite structure has a long lifetime and is easy to replace.

The lower part using the gravity automatic devices can keep constant tension force, avoid skid or take off the chain and get certain yield ability, effectively protect lower shaft parts and other parts when hoppers get stuck accidentally.

1. High capacity. The capacity is 1 times higher than the HL bucket elevator in the same bucket width.

2. Adopt packaged sprocket, consisted of wheel body, sprocket rim which are connected by high strength bolt. It is convenient to unscrew the bolt and change the sprocket rim after the sprocket wheel wears to a certain degree, which can save material, reduce maintenance costs.

3. The heavy-duty lever tensioning device makes automatic tension be realized. Once installed, no need to adjust, and it can keep constant tension, ensure the normal operation and avoid the skid or take off the chain.

4. Stable lifting height, reliable operation, low noise, easy maintenance.

5. The conveying capacity of the improved model is 30% higher than normal models.

6. The drag part is high strength low alloy steel chain whose life is long. After proper heat treatment, the steel chain has very high tensile strength and wears resistance.

|

Link Chain Bucket Elevator Model |

TH160 |

TH200 |

TH250 |

||||

|

Hopper Type |

ZH |

SH |

ZH |

SH |

ZH |

SH |

|

|

Capacity/(m³/h) |

15.77 |

24.97 |

17.87 |

28.6 |

31.43 |

48.19 |

|

|

Hopper |

Volume (L) |

1.2 |

1.9 |

1.5 |

2.4 |

3.0 |

4.6 |

|

|

Interval (mm) |

500 |

|||||

|

Chain |

Round Steel Diameter*Pitch(mm) |

14*50 |

|||||

|

|

Single Load(KN) |

≥190 |

|||||

|

Hopper Running Speed/(m/s) |

1.2 |

1.2 |

1.2 |

||||

|

Drive Sprocket Rotation Speed(r/min) |

69.71 |

63.22 |

44.11 |

||||

|

Conveying largest size(mm) |

20 |

25 |

30 |

||||

|

Link Chain Bucket Elevator Model |

TH315 |

TH400 |

TH500 |

TH630 |

|

|||||||

|

Hopper Type |

ZH |

SH |

ZH |

SH |

ZH |

SH |

ZH |

SH |

|

|||

|

Capacity/(m³/h) |

35 |

59 |

58 |

93 |

81 |

130 |

145 |

210 |

|

|||

|

Hopper |

Volume (L) |

3.75 |

6 |

5.9 |

9 |

9.3 |

15 |

15 |

24 |

|

||

|

Interval (mm) |

512 |

688 |

|

|||||||||

|

Chain |

Round Steel Diameter*Pitch(mm) |

φ18*64 |

φ22*86 |

|

||||||||

|

Single Load(KN) |

≥320 |

≥480 |

|

|||||||||

|

Hopper Running Speed/(m/s) |

44 |

37.6 |

39.7 |

35.8 |

||||||||

|

Conveying largest size(mm) |

35 |

40 |

50 |

60 |

||||||||

Help customers to select equipment

Free arrangement of engineers to the site for actual survey and plan design

Strict implementation of quality standards, quality assurance of ex-factory products

Free logistics and transportation information, more choices for logistics and transportation

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

Free arrangements for engineers to guide the basic production of equipment

Provide free technical guidance for equipment installation and commissioning

The free on-site one-to-one operation, repair, maintenance, and other training

Professional after-sales service team, 24 hours response to customer needs

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

CE, ISO9001

factory sell directly

30 years experience, professional

Processing ability: 15.77-210 m³/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.