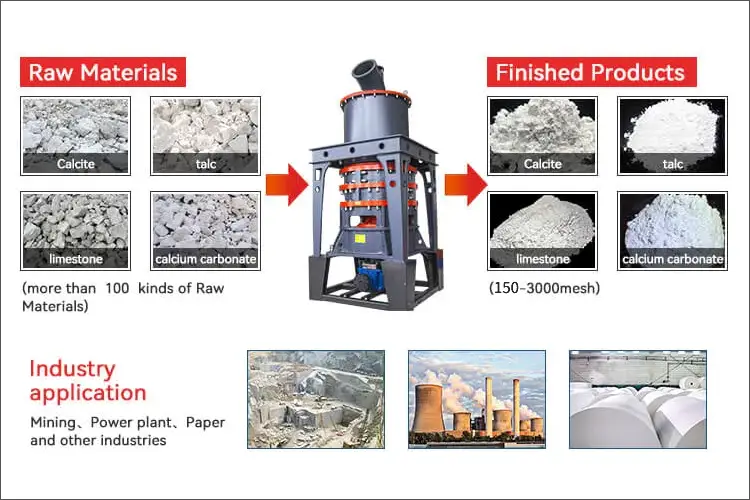

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

14/12/2023 admin

Five application scenarios of carbon black powder

At present, the refined cracked carbon black industry is in the development stage. The high added value brought by ultra-fine milling has made its industrial use increasingly widespread: mainly used as a key material for solar cells; highly adsorbent and used as a pollutant adsorbent, etc.

In 2018, a Turkish customer contacted SBMmill for the first time as a middleman and purchased equipment for the grinding link in the cracked carbon black production line and exported it to South Korea.

Based on specific needs, SBMmill selected the star product in the HGM series: HGM-100L-II ultra-fine grinding mill, and went to South Korea to help build the infrastructure of the local carbon material industry.

In South Korea, the smooth operation of the equipment impressed middlemen so much that Turkish customers proposed to purchase additional models of the same model this year.

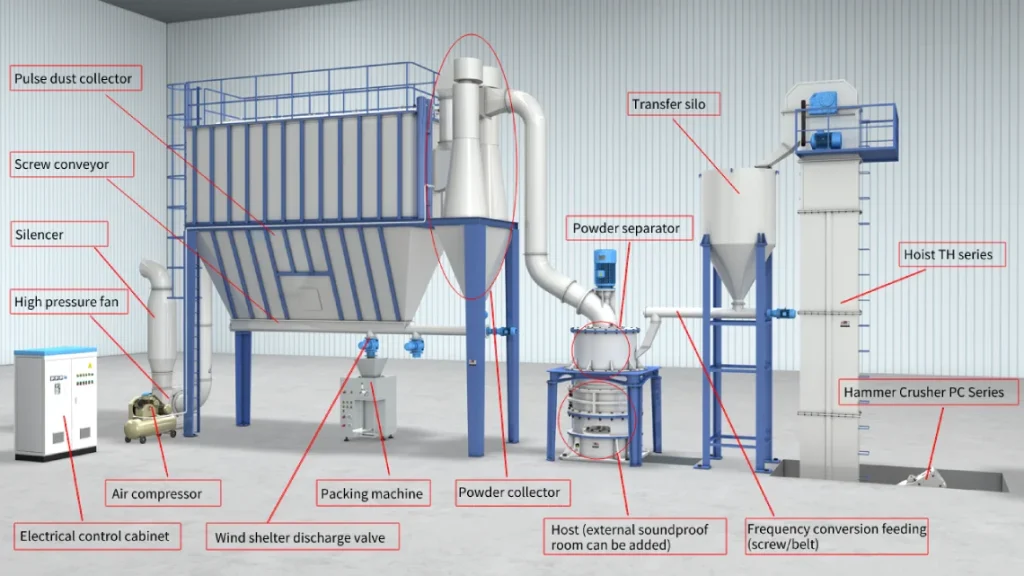

SBMmill is an important integrated production, research and marketing center for large-scale machinery and equipment in China. The production department attaches great importance to customers’ production timeliness requirements and expedites production arrangements. A heavy flour mill with an output capacity of 1-9 tons per hour, an adjustable fineness range of 200-2500 mesh (loaded with a powder separator), excellent finished grain shape, and a large specific surface area will go straight to Turkey on a starry night.

In order to ensure a smooth start-up, SBMmill technicians adhere to the service credo of full-time, full-time and dedication. In addition to providing remote guidance for independent installation, they also open a dedicated line for the technical department around the clock to ensure that problems are solved within a few hours.

During the test and debugging process, members of the after-sales team will go directly to the site after approval. The whole line of the project is a standardized HGM series 100L-II ultra-fine mill, used to produce ultra-fine carbon black powder.

SBMmill has never stopped on the road of exploring powder perfection. After five years of iterative upgrades, the HGM series has taken on a completely new look:

● Negative pressure throughout the entire process strengthens clean production capabilities

The non-contact grinding roller and grinding plate significantly reduces the vibration of equipment operation; the entire equipment is sealed, and the finished products are directly input into the finished product warehouse without dust spillage.

● 150-2500 mesh adjustable fineness range

The multi-stage powder selection and grading structure ensures the fineness of D975-45μm finished products; the precision rotor equipped with PLC frequency conversion control system adds high added value.

● Safe and reliable all-weather operation system

The PLC/DCS automatic control system is adopted to replace manual operation; the grinding roller sleeve and the grinding plate lining adopt electronic limit + mechanical limit dual protection, giving all-weather operation capability.

During the project return visit, Turkish customers spoke highly of SBMmill equipment and expressed that there is broad space for cooperation and a deep foundation for cooperation in future export sales. Five years have passed by, and SBMmill insists on using more sophisticated, refined and precise equipment to move forward together with Turkish customers.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.