The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 325-6000 mesh

Feed size.: 200-400 mesh

Output: 0.6-5 T/H

Product features: With its flexible system in parallel or in series, it is capable of meeting the diversified needs of the clients. The fineness can reach 2 microns with a 90% passing through rate per single mill one time.

The LXMC ultra fine wet stirring mill is wet mill equipment developed by SBM. The ultrafine wet stirring mill is very flexible in use and can be formed into a parallel or series system to meet the diverse needs of customers. The finished product’s fineness can reach 2 microns, and the single-pass rate is 90%.

The ultra-fine wet stirring mill can be used to grind calcium carbonate, soft and hard kaolin, coal water slurry, mica, barite, gypsum, rare earth, magnesium oxide, aluminum oxide, iron oxide red, and magnetic materials. The product fineness can reach the micron and sub-micron levels.

papermaking

The final products obtained by an ultra-fine wet stirring mill can be directly used in paper fillers and coatings.

Or used in coatings, paints, cosmetics, diapers, plastics, PVC, rubber fillers, wires, and cables after drying.

coating

pigment

rubber

PVC

plastic

Ink

The multi-stage mixer is driven by the transmission device of the ultra-fine wet mill to generate multi-dimensional rotation power.

The mixer tank is made by high resist abrasion with an odd shape. Materials are grind by weight and pressure of smooth surface balls and the stress of screw rotating centrifugal stress produced by friction, extrusion and shear, gentle rub and under the action of impact force, effectively.

The mixer is made of tungsten carbide alloy, which is called “industrial teeth”. Reasonable linear velocity can effectively reduce the starting torque. Greatly reduce the wastage of the mill grinding meson balls, the pulp whiteness no effect. Improve equipment operation efficiency and prolong the service life. The material properties will do not change.

The feed size of the wet grinding mill is 200-400 mesh, and the single machine can grind products below 2 microns or D90 (6000 mesh). Optimization of the length to diameter ratio for pulp residence time is long, the material running route is long, high crushing ratio, uniform particle size distribution, particle shape is spherical.

Related knowledge: Characteristics and Application of Wet Superfine Crushing Process

1. Ultrafine powders, the finest powders, reach 2 microns with a content of 90% for milling one time.

2. Widely used in many industries:

Products can be directly used for paper filling, coating, or after drying for coatings, paints, cosmetics, disposable diapers, plastic, PVC, and rubber filler wire and cable. Has a large output, high efficiency, low energy consumption, environmental protection, and other features.

3. High productivity, high grinding efficiency, low energy consumption.

4. Reliable and stable mechanical properties. Vertical-shaped star wheel reducer higher transmission efficiency, run more smoothly.

5. Low consumption of grinding media, non-polluting. The temperature is low for finished products, good liquidity.

6. The components inside the mill with high hardness wear-resistant materials, long service life.

7. Compact structure, suitable height, easy operation and maintenance, stable production, automatic controlling is optional.

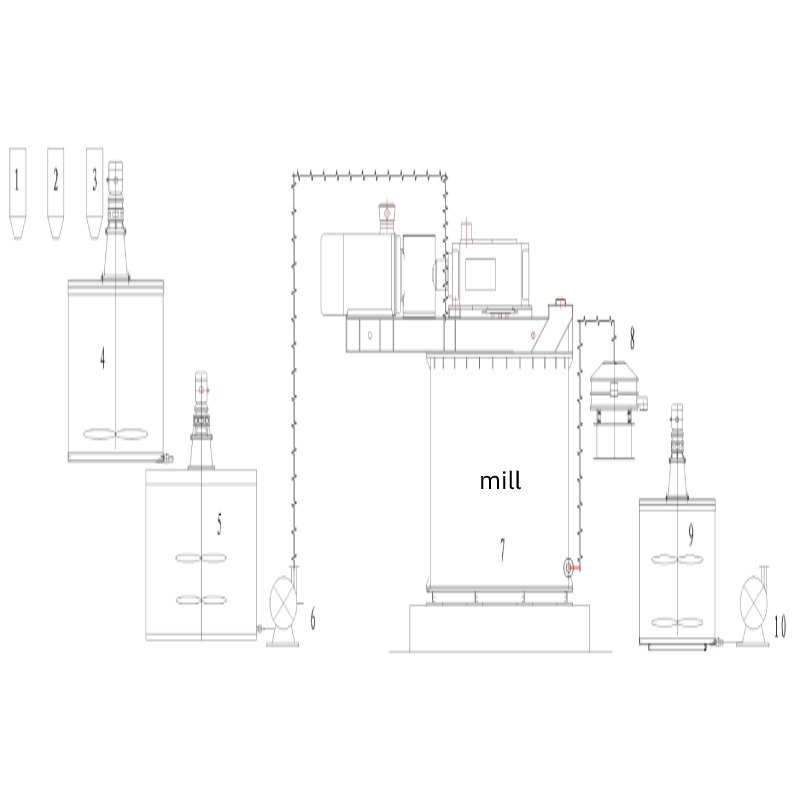

1. Powders

2. Water

3. Disperse

4. Slurry pump

5. Buffering pump

6. Pump

7. Wet stirring mill

8. Vibrating feeder

9. Barrel to be checked

10. Pump

There are 3 models of LXMC ultra fine wet stirring mill.

Model 1: LXMC1000

Product standard: National Q/AEHM001-2010

Overall dimensions: 2700 mm (Length) x2200mm (Width) x4500mm (Height)

Motor: 132KW 380V

Cooling method & Volume: Cooling and Flow: water cool 10M3/h (Recycle)(recyclable).

Feeding method: bottom side tangential feed.

Meson ball first installed capacity: about 1T (specific gravity 3.2).

Quality of equipment: about 7T without load, about 11T heavy load.

LXMC1000 Technical Specification:

| Technique | Single mill | Two mills in Series | |

| Powder finness -2 micron | D60 | D90 | D95 |

| Solid content | 70%-75% | 70%-75% | 70%-75% |

| Capacity per hour (dry materials) | 1.4-1.8 | 0.6-0.8 | 0.7-0.9 |

| The dosage of dispersants(Kg/t) | 4 | 10 | 14 |

| Grinding meson balls loss(Kg/t) | 0.2-0.4 | 0.5-0.6 | 0.8-1.2 |

| Power consumption(KW/t) | <45 | <130 | <170 |

Model 2: LXMC3600

Product standard: National Q/AEHM001-2010

Overall dimensions: 3600 mm (length)×3600 mm (width)×8700 mm (height)

Motor: 250kw 380V

Cooling method & Volume: Cooling and Flow: water cool 15M3/h (recyclable)

Feeding method: bottom side tangential feed.

Meson ball first installed capacity: about 3.5T (specific gravity 3.2)

Quality of equipment: about 12T without load, about 20T with a heavy load.

LXMC3600 Technical Specification:

| Technique | Single mill | Two or more mills in series | ||

| Powder finness -2 micron | D60 | D90 | D95 | D98 |

| Solid content | 70-76% | 70-76% | 70-76% | 70-76% |

| Capacity per hour (dry materials) | 3-3.8 | 1-1.5 | 1.8-2.2 | 1.5-1.8 |

| The dosage of dispersants(Kg/t) | 4 | 8 | 12 | 15 |

| Grinding meson balls loss(Kg/t) | 0.3-0.4 | 0.5-0.6 | 0.8-1.0 | 0.8-1.2 |

| Power consumption(KW/t) | <40 | <125 | <145 | <180 |

Model 3: LXMC5600

Product standard: National Q/AEHM001-2010

Overall dimensions: 4200 mm(Length)×2380 mm(Width)×3500 mm(Height)

Motor: 355kw 380V

Cooling method & Volume: Cooling and Flow: water cool 15M3/h (Recycle)(recyclable)

Feeding method: bottom side tangential feed

Meson ball first installed capacity: about 4.5T (specific gravity 3.2)

Quality of equipment: about 15T without load, about 25T heavy load

LXMC5600 Technical Specification:

| Technique | Single Mill | Two or more mills in series | |

| Main unit quantity | 1 mill | 2 mills | 3 mills |

| Solid content | 70%-76% | 70%-76% | 70%-76% |

| Powder finness -2 micron | D60 | D75 | D98 |

| Capacity per hour(dry materials) | 4.5-5 | 4.5-5 | 4.5-5 |

| The dosage of dispersants(Kg/t) | <5 | <6 | <15 |

| Grinding meson balls loss(Kg/t) | 0.3-0.4 | 0.4 | 1-1.2 |

| Power consumption(KW/t) | <40 | <50 | <185 |

Help customers to select equipment

Free arrangement of engineers to the site for actual survey and plan design

Strict implementation of quality standards, quality assurance of ex-factory products

Free logistics and transportation information, more choices for logistics and transportation

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

Free arrangements for engineers to guide the basic production of equipment

Provide free technical guidance for equipment installation and commissioning

The free on-site one-to-one operation, repair, maintenance, and other training

Professional after-sales service team, 24 hours response to customer needs

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

CE, ISO9001

factory sell directly

30 years experience, professional

Particle size is adjusted primarily by a change in feed rate. When the rate is reduced, finer particles result because there is more energy available per particle to accelerate the particles and the entire fluid mass. Collisions become more violent and pressure gradients become larger.

8 years. Since the foundation of our company, we have been manufacturing the machine, which updated many times, now the machine runs stable and of high quality.

We have passed CE&ISO9001:2008, and our crushers & mills have been exported to Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, America, etc.

Model: LXMC1000, LXMC3600, LXMC5600

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.