The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

25/07/2022 admin

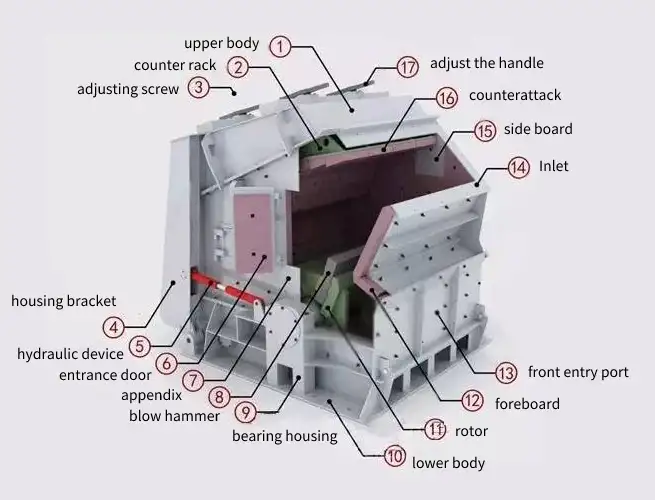

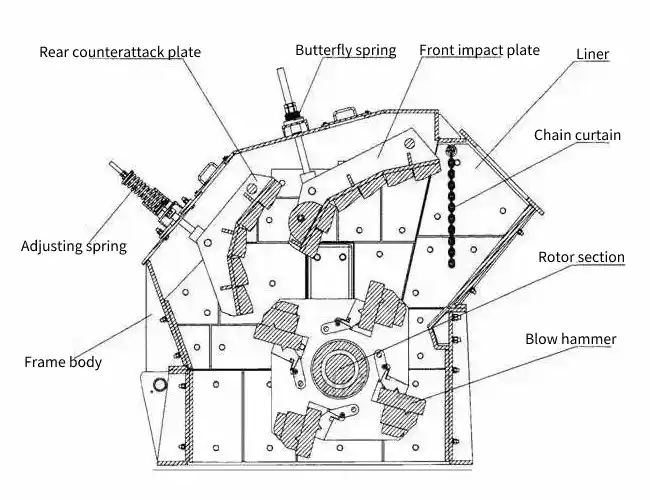

The impact crusher has a unique working mechanism and structural design features.

(1) The discharge granularity is uniform, the discharge is in the shape of a cube, and the content of fine powder and dust is low.

(2) Low operating cost and low investment cost. The total weight of the impact crusher is lighter than that of the hammer crusher, the external dimensions are small, and the dynamic and static load values are low, which can effectively reduce the civil construction cost. At the same time, the required motor power is low, which can effectively reduce the power consumption of the equipment and reduce the operating cost of the equipment.

(3) The wearing parts of the impact crusher have a long service life and low long-term operating costs.

PFW Impact Crusher

Output Size: 0-200 mm

Feed size: 350 mm

Capacity: 90-450 t/h

Application: Almost all minerals, such as quartz, mica, calcite, gypsum, limestone, marble, coal, slag, iron ore, copper ore, refractory material, glass, etc.

Through the above three analyses, the impact crusher has the following five advantages over the hammer crusher:

Advantage 1: It can handle materials with high moisture content and prevent clogging

The impact crusher can effectively deal with materials with large moisture content and prevent the blockage of the crusher.

When the water content of the material is too large, the feed chute and the impact plate of the impact crusher can be equipped with a heating device to prevent the material from sticking. The impact crusher does not need to be equipped with a bottom sieve plate, which can effectively prevent clogging. The hammer crusher cannot use heating to prevent the material from sticking, and must be equipped with a bottom screen, which increases the possibility of blockage.

Advantage 2: Wide material adaptability

The impact crusher is suitable for both soft and very hard materials.

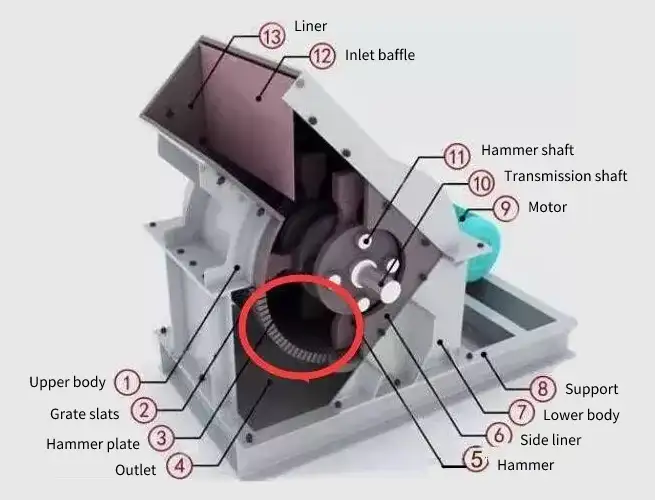

The plate hammer of the impact crusher is firmly fixed on the rotor by a mechanical clamping structure, and has a large moment of inertia when rotating with the rotor. Compared with the hammer crusher (the hammer head is in a suspended state), the rotor of the impact crusher has greater momentum, which is suitable for crushing harder materials and has lower energy consumption.

Advantage 3: Wider range of discharge adjustment

The impact crusher can easily and flexibly adjust the discharge particle size, and the adjustment range is wide.

The impact crusher can adjust the discharge particle size in various ways, such as adjusting the rotor speed, adjusting the gap between the impact plate and the grinding chamber, etc. The gap adjustment can be adjusted mechanically or hydraulically. The hydraulic adjustment system can easily adjust the gap through the local operation button or the travel control system. The hammer crusher can only adjust the discharge particle size by replacing the bottom sieve plate.

Advantage 4: Less wear and tear of wearing parts

The wear of the wearing parts of the impact crusher is smaller than that of the hammer crusher, and the metal utilization rate is higher.

The wear of the blow hammer of the impact crusher only occurs on the side facing the material. When the rotor speed is normal, the feed material will fall to the surface of the blow bar (strike surface), and the back and sides of the blow bar will not be worn. Even the side facing the material suffers very little wear. And the bottom grinding bar is also easy to replace. The metal utilization rate of the impact crusher plate hammer can be as high as 45%-48%. The hammer head of the hammer crusher is in a suspended state, and the wear occurs on the upper, front, rear and side surfaces. Compared with the plate hammer, the hammer head wears more seriously, and the metal utilization rate of the hammer head is only about 25%. Also the rotor body itself may be subject to wear. The sieve plate at the bottom of the hammer crusher is seriously affected by wear and tear.

Advantage 5: The replacement of spare parts is easy and the maintenance cost is reduced accordingly

Only 6 blow bars are installed on the rotor of the impact crusher, and it takes a short time to replace a set of blow bars. The replacement of the grinding rod in the bottom grinding chamber only takes tens of minutes, which greatly reduces the time and cost of inspection and maintenance. The hammer crusher has more than 100 hammer heads. It takes a lot of time and manpower to replace a set of hammer heads, and the repair and maintenance costs are high.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.