The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

23/11/2022 admin

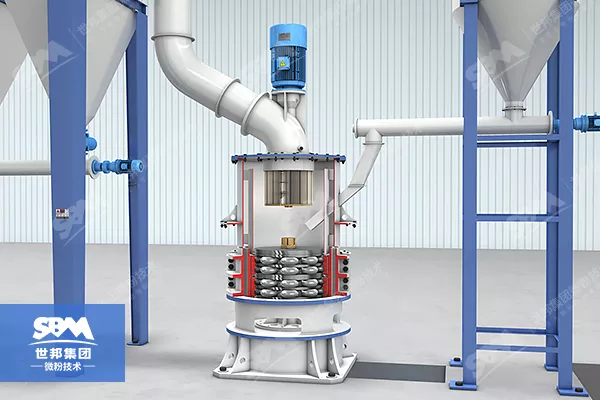

SBM Group CLUM ultra-fine vertical powder grinding mill as the crystallization of mid-end advanced technology has become the latest product leading the trend of mill machines in the world. It is widely used in non-flammable and explosive brittle materials, such as calcium carbonate, carbon black, mica, talc, graphite, quartz, fluorite, calcite, limestone, dolomite, coal and other fine powder and ultra-fine powder processing. Its extremely fine product fineness has become the iconic advantage of this series of equipment.

CLUM ultra-fine vertical powder grinding mill

Discharge fineness: 150-3000 mesh

Feed size: <15 mm

Output: 1-20 T/H

Range of application: Calcium Carbonate, Limestone, Gypsum, Kaolin, Dolomite, Barite, Feldspar…

Product features: It has high grinding efficiency, low energy consumption, uniform particle shape, narrow particle size distribution, good fluidity, and strong product adaptability.

The particle size of the CLUM ultra-fine vertical powder grinding mill can reach 150-3000 mesh, the fineness of the maximum up to 3500 mesh. An ordinary powder separator can not effectively select the powder in this fineness range. After the introduction of technology and field tests, SBM CLUM ultra-fine powder mill using multiple powder separator configuration, in the efficiency of powder selection and powder particle size distribution has obtained a breakthrough technical improvement. As the third generation of the efficient separator series, multi-head classifier has a breakthrough improvement in powder efficiency and powder fineness.

The multi-head classifier adopts the arrangement of multiple small-diameter cage separators, the impeller adopts horizontal structure, and all of them are controlled by frequency converter. Each impeller is equipped with a speed measuring device, through the feedback signal to accurately control the impeller speed, to ensure the stability of the powder fineness. When working, the motor drives the impeller to rotate through the shaft. Due to the suction effect of the external fan, the ground powder will go to the impeller with the wind. Because the wind from the impeller clearance flow, the powder will be through the impeller analysis and selection to go through the powder separator. Such a large powder is not easy to enter the impeller is thrown to the inner cylinder wall down to the top bulk tray, re-grinding.

According to the engineer of SBM Group mill, the multi-head classifier produced by German technology can effectively improve the precision of powder selection, the fineness of the product can be adjusted between 325 mesh and 3000 mesh, and the fineness of the product can reach d97≤5μm at one time.

At present, the CLUM ultra-fine vertical powder grinding mill is the company’s largest model of ultra-fine milling, and also the biggest micro-milling in the industry. Compared with other models, it was CLUM1736 Ultra-fine grinding not only uses multi-head separator, and each rotor can frequency control, the fineness of grinding products can be achieved in the selected range, but does not need to go through the secondary wind separation classification, there is no material.

According to the customer service department, a company producing ultrafine powder in Guangxi, China purchased two sets of CLUM ultrafine mill from Shanghai Shibang for processing calcium carbonate. Day operation 11 hours, the person in charge of the company said: “I have been engaged in the ultrafine grinding industry for more than ten years. Shanghai Shibang products are very good. Our finished products supplied to more than 60 manufacturers, widely used in paper, paint, paint, PVC and other industries, have been widely recognized by customers.” And this customer purchased grinding equipment from us again this year and added a new calcium carbonate powder grinding production line.

In the realm of industrial mineral processing, the demand for robust, high-output rock pulverizer machines has never been greater. Among the most advanced solutions in this field is the HGM series of ultrafine grinding mills, engineered to deliver precision, durability, and scalability for large-scale operations. This article delves into the flagship HGM125 model and its…

A ring mill, also known as a ring roller mill, micro powder grinding mill, or ultrafine grinding mill, is a type of grinding equipment commonly used in the industrial production of ultrafine calcium carbonate.

The CLQM series Airflow Vortex Mill Powder Micronizer is designed for processing a wide range of materials, offering uniform particle sizes that can be adjusted according to specific requirements. The CLQM airflow vortex mill powder micronizer is capable of grinding materials to micron and sub-micron levels, making it highly versatile and suitable for processing difficult-to-handle…

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultra-fine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying.

Ultrafine vertical mill is a high-efficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc

Carbon black is a light, loose and fine black powder that contains carbon substances. It can be used as a black dye to make ink, paint, rubber material, etc. Carbon black ultrafine mill is also called (three-ring four-ring) medium-speed ring roller micro-grinding machine. It adopts a graded continuous grinding method to grind the material multiple…

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.